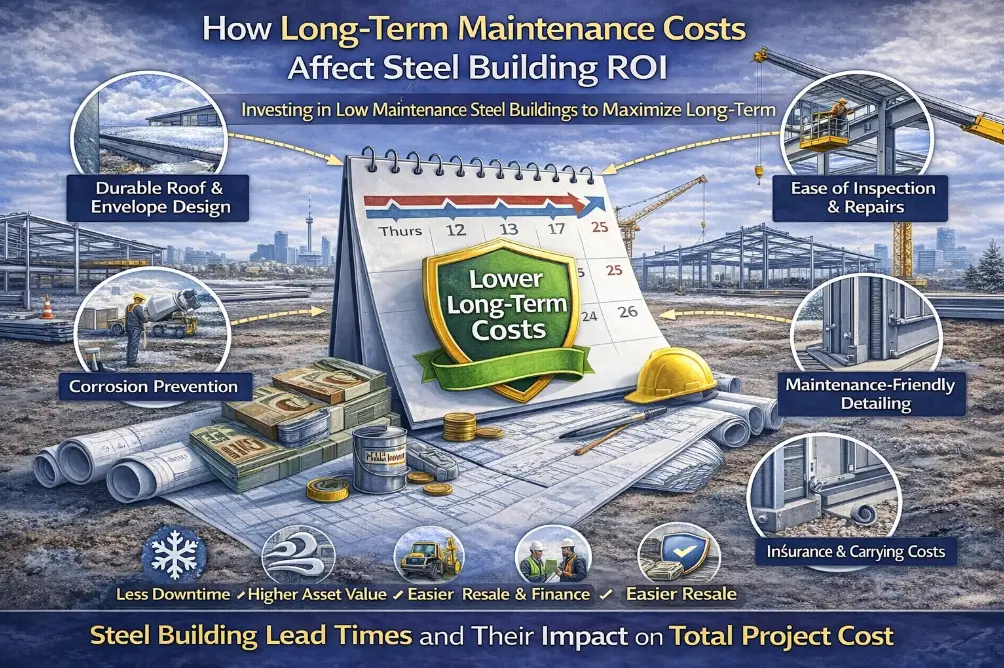

In steel construction, the initial purchase price is often the most visible number and the least meaningful one. While upfront cost matters, it represents only a fraction of what a building will actually cost over its working life. For owners planning permanent steel buildings in Canada’s variable climates, long-term performance, durability, and predictability typically determine whether a project becomes a reliable asset or a recurring expense.

Paying more upfront does not automatically mean better value. But investing selectively in the right areas often reduces maintenance costs, avoids disruptions, and protects the building’s functional and financial lifespan over several decades. The challenge is knowing where additional upfront investment produces real long-term return, and where it does not.

This article explains when higher initial steel building costs lead to lower total ownership cost over a 40-year horizon, and when they do not.

Why Upfront Cost Is a Poor Measure of Long-Term Value

Steel buildings are frequently compared using headline prices that focus on material quantities or basic dimensions. These comparisons often overlook factors that determine how the building performs over time, including structural detailing, environmental exposure, construction quality, and coordination between design and use.

Over a 40-year period, operating costs, maintenance, repairs, downtime, and modifications often exceed the original construction cost. Owners who analyze true steel building pricing beyond upfront quotes typically achieve significantly lower total ownership cost. Decisions made during design and procurement quietly shape these costs long after construction is complete.

The goal is not to minimize upfront cost, but to minimize total cost of ownership.

The Difference Between Cost and Investment in Steel Buildings

An upfront expense becomes an investment only when it reduces future costs or risk. In steel construction, this distinction matters.

Examples of upfront spending that often produces long-term savings include:

- Engineering that reflects real site conditions rather than minimum assumptions

- Protective coatings selected for actual exposure, not just compliance

- Structural allowances for future equipment, loads, or expansion

- Proper envelope detailing that reduces condensation and corrosion risk

- Construction sequencing that prevents rework and inspection failures

By contrast, paying more for features that do not align with use, exposure, or lifecycle requirements rarely improves return.

Structural Engineering Accuracy and Lifecycle Cost

Accurate engineering is one of the most reliable drivers of long-term savings. Structural design in Canada is governed by climate-specific loading requirements published in the National Building Code of Canada (structural load provisions).

Many long-term overruns occur when early assumptions are wrong, which is why engineering errors that increase steel building costs must be identified before design is finalized.

Buildings designed too lightly may meet minimum code requirements but experience deflection issues, fatigue, or serviceability problems that require correction later. Buildings designed excessively heavy may carry unnecessary material cost without corresponding benefit.

The most cost-effective structures are engineered precisely for:

- Actual loads, not generic assumptions

- Regional snow, wind, and seismic conditions

- Equipment placement and operational use

- Foundation interaction and settlement tolerance

Long-term steel building performance in Canada is regulated under CSA A660 steel building system standards.

Over decades, accurately engineered steel structures require fewer reinforcements, experience less distortion, and maintain predictable performance under repeated loading. These benefits compound over time.

Foundations and Early Coordination Pay Back for Decades

Foundation issues are among the most expensive problems to correct after construction. Small compromises during early stages often result in recurring costs through settlement, cracking, drainage issues, and structural adjustment.

Long-term performance is heavily influenced by ground conditions, making soil conditions affecting steel building foundations in Canada a major factor in ownership cost.

Upfront investment in:

- Proper geotechnical investigation

- Foundation coordination with steel reactions

- Drainage and grading planning

- Frost protection appropriate to Canadian climates

reduces long-term repair costs and prevents performance degradation that accelerates maintenance spending.

Foundations rarely fail suddenly. They fail gradually, quietly increasing cost and operational disruption over decades.

Envelope Performance and Long-Term Operating Cost

The building envelope plays a major role in long-term operating expense, particularly in Canadian climates. Buildings designed with accurate climate data in mind, especially Canada’s steel building snow load zones, consistently experience lower repair and energy costs.

Investing upfront in:

- Correct insulation strategy for the building’s use

- Vapour control appropriate for occupancy and internal conditions

- Condensation-resistant detailing

- Durable roof and wall systems suited to snow, wind, and moisture exposure

often reduces heating costs, minimizes corrosion, and extends component life.

Envelope failures do not usually appear immediately. They reveal themselves through rising energy bills, condensation damage, corrosion, and interior deterioration over time.

Protective Coatings and Environmental Exposure

Steel durability depends heavily on environmental exposure. Buildings located near roadways, agricultural operations, industrial processes, or lake-influenced environments experience accelerated corrosion if coatings are not selected appropriately.

Upfront investment in coating systems matched to exposure conditions often:

- Extends repainting cycles

- Reduces corrosion repair

- Preserves structural capacity

- Protects resale value

Choosing coatings based solely on minimum specification often leads to higher cumulative maintenance costs over decades.

Designing for Adaptability and Future Use

Buildings that can adapt retain value longer. Many steel buildings outlive their original purpose, but only if they can accommodate change.

Upfront design decisions that support adaptability include:

- Clear spans where operational flexibility matters

- Allowance for future cranes, equipment, or mezzanines

- Roof and wall capacity for additional services

- Foundation design that accommodates expansion

The cost of accommodating future change during initial construction is often far lower than retrofitting later. Over 40 years, adaptability protects both function and value.

Construction Quality and Inspection Outcomes

Paying more upfront for disciplined construction practices often reduces long-term cost in ways that are not immediately visible.

Projects that prioritize:

- Proper sequencing

- Clear erection procedures

- Trade coordination

- Inspection readiness

experience fewer corrections, fewer compromised details, and fewer hidden defects.

Many costly performance issues originate during erection, which is why understanding steel building erection timelines and what slows projects down is essential for long-term value.

Deficiencies concealed during construction often surface years later through leaks, corrosion, misalignment, or operational limitations. Correcting these issues after occupancy is almost always more expensive.

Downtime and Operational Disruption

For commercial, agricultural, and industrial owners, downtime is often the most expensive hidden cost.

Buildings that experience:

- Roof leaks

- Structural deflection

- Envelope failure

- Equipment interference

can interrupt operations repeatedly over decades.

Even a single roof leak in an operational facility can disrupt production, inventory storage, or livestock protection. These impacts often cost far more than the repair itself and tend to compound when disruption becomes recurring rather than isolated.

Upfront investment that reduces the likelihood of these issues often saves far more than the initial premium when measured against lost productivity and operational instability.

Maintenance Predictability and Budget Stability

Well-designed steel buildings do not eliminate maintenance, but they make it predictable.

Predictable maintenance allows owners to:

- Budget accurately

- Schedule work efficiently

- Avoid emergency repairs

- Preserve asset value

Buildings constructed to minimum standards often experience irregular, reactive maintenance that increases both cost and uncertainty over time. Long-term performance data shows that steel building maintenance ROI over decades strongly favours durability-focused design.

Resale Value and Long-Term Asset Performance

Buildings with documented performance, predictable maintenance history, and durable construction consistently retain higher resale and refinancing value.

Buyers and lenders evaluate:

- Structural condition

- Envelope integrity

- Maintenance records

- Remaining service life

Upfront investments that improve these factors protect long-term asset value and financial flexibility.

When Paying More Upfront Does Not Make Sense

Not every upgrade produces return. Paying more upfront rarely makes sense when:

- The structure is temporary

- The building will be relocated or removed

- Operational demands are minimal

- Exposure conditions are low

- The ownership horizon is short

The key is aligning investment with intended use and ownership duration.

Making Cost Decisions with a 40-Year Perspective

The most successful steel building projects begin with a clear understanding of how the building will be used, maintained, and adapted over time. Projects delivered through turnkey steel building solutions consistently achieve better lifecycle cost control and fewer coordination failures.

Owners who evaluate decisions through a 40-year lens tend to:

- Experience fewer surprises

- Spend less on corrections

- Preserve operational continuity

- Retain asset value longer

In steel construction, initial price is a moment. Lifecycle cost is the story that follows.

Final Perspective

Paying more upfront only saves money when it is spent intentionally, in the right places, for the right reasons. Over 40 years, steel buildings reward accuracy, coordination, durability, and foresight.

Over decades of ownership, steel buildings do not reward the lowest bid. They reward foresight.

Reviewed by the Tower Steel Buildings Engineering Team

This article was reviewed by the Tower Steel Buildings engineering team, drawing on decades of combined experience in structural steel design, fabrication coordination, and long-term performance evaluation of steel buildings across Canada. The review focused on lifecycle cost accuracy, maintenance realities, and how early design decisions affect building performance over extended ownership periods.

1. Does paying more upfront always mean a better steel building?

No. Higher upfront cost only creates value when it is directed toward elements that reduce long-term maintenance, operational disruption, or performance risk. Spending more on features that do not align with actual use or exposure rarely improves return over time.

2. What upfront investments have the biggest impact on long-term cost?

Accurate structural engineering, foundation coordination, envelope design suited to climate and use, and protective coatings matched to environmental exposure tend to produce the greatest long-term savings. These elements reduce corrective work and unpredictable maintenance over decades.

3. How does climate affect long-term steel building costs in Canada?

Canadian climates expose buildings to snow, wind, freeze-thaw cycles, and moisture. Buildings designed with these conditions in mind typically experience lower maintenance escalation and fewer performance issues over time compared to structures designed only to minimum assumptions.

4. Can long-term maintenance costs exceed the original building price?

Yes. Over a 40-year ownership period, cumulative maintenance, repairs, and operational disruptions can exceed the original construction cost if early design and construction decisions are not aligned with lifecycle performance.

5. Does better engineering reduce future renovation costs?

In many cases, yes. Buildings engineered for future loads, equipment, or expansion typically require fewer structural modifications later. This reduces both direct renovation costs and operational downtime during changes.

6. How does long-term performance affect resale value?

Buildings with predictable maintenance histories, durable construction, and documented performance tend to retain higher resale and refinancing value. Buyers and lenders place significant weight on long-term condition and remaining service life.