When buyers evaluate a steel building project, most focus on the quoted price of the structure itself. Size, clear span, insulation, doors, and finishes usually dominate early discussions. What often receives far less attention is lead time, even though it can quietly become one of the most expensive variables in the entire project.

Steel building lead times affect far more than delivery dates. They influence financing costs, insurance requirements, construction scheduling, labour availability, foundation timing, seasonal risk, and overall project predictability. In many cases, poorly managed lead times add more cost than upgrading the building itself.

This guide explains how steel building lead times work in Canada, why they vary, and how they directly impact total project cost from planning through completion.

What Does “Lead Time” Mean in a Steel Building Project?

In steel construction, lead time refers to the period between final approval of engineered drawings and delivery of the steel package to site. Lead time officially begins after steel building engineering approval is completed and drawings are finalized. It does not begin at contract signing.

Lead time typically includes:

- Final engineering and structural review

- Shop drawings and approvals

- Material procurement

- Fabrication and quality control

- Packaging, logistics, and transport

Each step must occur in sequence. Delays in any one phase can affect the entire construction schedule.

This distinction matters because many first-time buyers assume lead time starts when a deposit is paid. In reality, fabrication does not begin until engineered drawings are fully approved. Engineering approval timelines align with requirements in the National Building Code of Canada.

Typical Steel Building Lead Times in Canada

While every project is different, most Canadian steel building projects fall within these general ranges after drawings are approved:

- Simple agricultural or storage buildings: 6 to 10 weeks

- Standard commercial or warehouse buildings: 8 to 14 weeks

- Large span or heavily engineered buildings: 12 to 20 weeks

These timelines assume design decisions are finalized early and material supply remains stable. Structural standards and fabrication guidance are supported by research from the National Research Council Canada. Design changes after approval almost always extend lead times.

Seasonality also plays a role. Spring and early summer typically bring the longest queues as buyers aim to start construction. Winter orders may move faster through fabrication but introduce weather-related risks later in the project.

Why Lead Times Vary Between Steel Building Suppliers

Not all steel building suppliers operate the same way. Lead times can vary significantly depending on how a manufacturer controls engineering, fabrication, and scheduling.

Key differences include:

Engineering Capacity

Suppliers with in-house engineering teams typically move faster and with fewer revisions. Outsourced engineering often introduces back-and-forth delays that extend timelines.

Fabrication Control

Manufacturers that fabricate steel internally control production schedules and quality. Suppliers relying on third-party fabricators compete for shop time, especially during peak seasons.

Material Sourcing

Steel availability, coatings, fasteners, and specialty components affect procurement timelines. Established supply chains reduce uncertainty.

Production Scheduling Discipline

High-volume suppliers may offer lower pricing but longer waits. Balanced scheduling often produces better overall project economics.

How Lead Times Increase Total Project Cost

Extended lead times do more than delay construction. They introduce secondary costs that are often underestimated or overlooked entirely.

Financing and Carrying Costs

Projects financed through loans or development capital accrue interest regardless of site activity. Delays between foundation completion and steel delivery can add weeks or months of carrying costs.

Extended lead times can also affect insurance binders and lender draw schedules, increasing administrative burden and holding costs for developers and commercial owners.

Foundation Timing and Exposure

Foundations poured too early may shown weather exposure, surface degradation, or require reinspection if steel delivery is delayed. These delays are often caused by incomplete steel building site preparation before delivery. This can lead to remediation costs or inspection delays.

Labour Availability and Rescheduling

Erection crews and trades are often booked months in advance. Delays can force rebooking at higher rates or create gaps that push construction into less favourable seasons. These issues often compound during steel building erection planning.

Seasonal Construction Risk

Missing a delivery window may shift erection into colder months, increasing costs related to heating, snow removal, weather protection, and reduced productivity.

Design Changes Are the Most Common Lead Time Disruptor

Late design changes remain the single biggest cause of extended lead times. Schedule resets caused by revisions are explained in design changes that affect steel building pricing.

Common examples include:

- Adding crane loads after engineering approval

- Changing door sizes or locations

- Modifying clear height or roof slope

- Upgrading insulation systems mid-process

Even small changes can trigger revised calculations, new drawings, and re-approval, often resetting the fabrication queue.

From a cost perspective, design certainty early in the project is one of the most effective ways to control total spend.

Imported Steel vs Canadian-Manufactured Lead Times

Imported steel buildings often appear cost-competitive on paper but introduce additional schedule risk. International transport timelines are influenced by regulations overseen by Transport Canada.

Common issues include:

- Longer transit times

- Port congestion and customs delays

- Limited recourse for missing components

- Extended replacement timelines

Canadian-manufactured steel buildings typically offer more predictable lead times and faster resolution if issues arise. The scheduling advantages of domestic supply are outlined in Canadian-manufactured steel buildings. When total project cost is considered, domestic production often proves more economical.

Lead Times and Foundation Coordination

Steel building foundation design and construction should be coordinated directly with expected steel delivery. Foundation timing must align with delivery schedules established during steel building foundation design.

Best practice includes:

- Completing geotechnical review early

- Finalizing foundation drawings alongside steel engineering

- Aligning foundation pour dates with confirmed fabrication schedules

Poor coordination can result in foundations sitting idle or being rushed prematurely, both of which increase cost and risk.

Speed vs Quality Control

Shorter lead times are not always better if they are achieved by bypassing normal engineering review or quality control. Structural review and quality benchmarks are aligned with standards published by CSA Group.

Compressed schedules that shortcut structural review or fabrication checks often result in:

- Field fit-up issues

- Missing components

- Rework during erection

These issues introduce costs far greater than the time saved. Proper quality assurance protects both schedule and budget.

Transparency Is a Cost-Control Tool

Suppliers who clearly explain how lead times work allow buyers to plan realistically. Clear scheduling communication is a core part of professional steel building services.

Reliable lead time communication includes:

- Written schedules tied to drawing approval milestones

- Clear definition of when fabrication begins

- Honest discussion of seasonal constraints

- Guidance on how design decisions affect timelines

This clarity allows better financing planning, contractor coordination, and risk management.

Why the Lowest-Priced Building Often Costs the Most

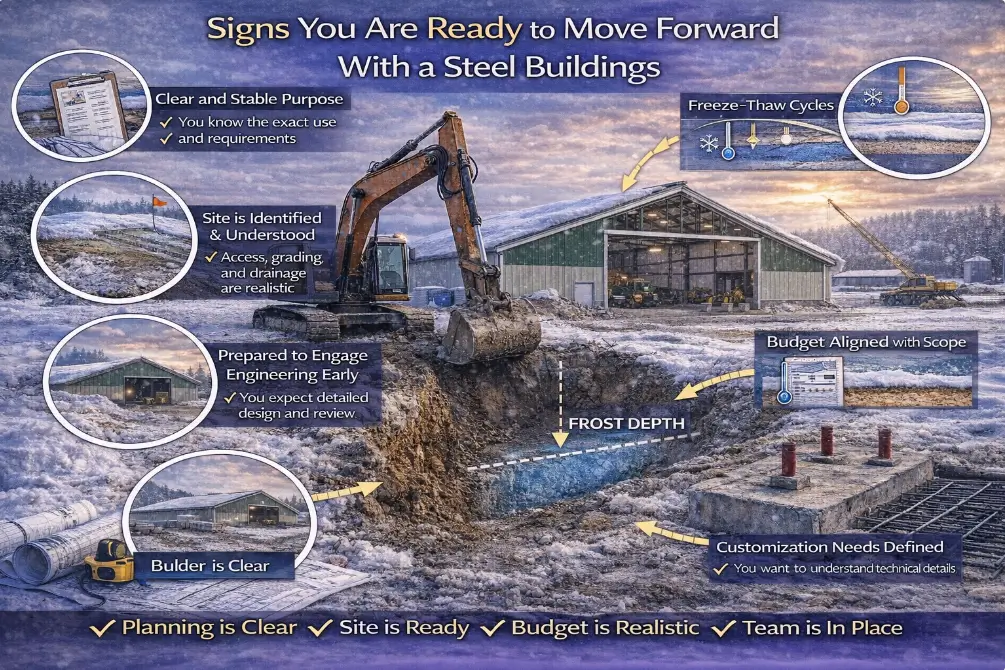

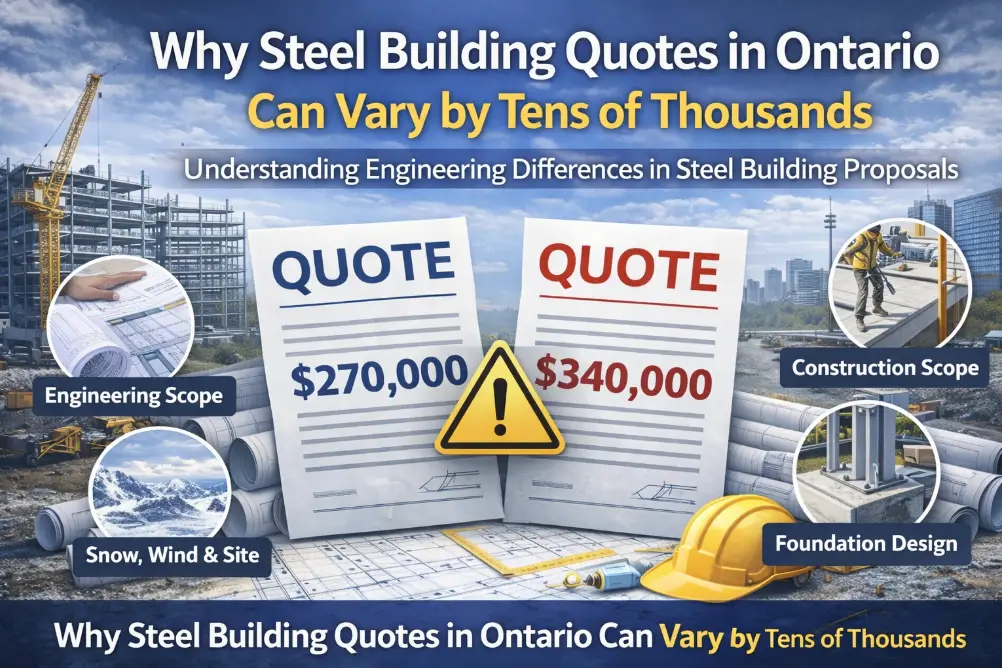

Buyers sometimes choose suppliers based solely on quoted price, only to discover that extended lead times inflate costs elsewhere. This is a common issue when comparing quotes, as explained in why steel building quotes vary.

The cheapest steel building on paper can become the most expensive project once financing, labour, seasonal exposure, and rescheduling are considered.

Experienced buyers evaluate:

- Total project timeline

- Lead time reliability

- Engineering and fabrication control

- Quality assurance processes

Predictability consistently outperforms speed when it comes to total project cost.

Managing Lead Time as a Strategic Advantage

Smart steel building projects treat lead time as a design and planning variable, not an afterthought.

Effective strategies include:

- Finalizing design decisions early

- Avoiding mid-stream changes

- Confirming lead times in writing

- Coordinating foundations, permits, and trades around delivery

When lead time is managed intentionally, projects stay predictable, costs remain controlled, and construction proceeds smoothly.

Final Perspective for Canadian Buyers

Steel building lead times are not just a scheduling detail. They are a primary driver of total project cost.

The cheapest steel building contract is rarely the lowest-cost project.

Projects that respect the realities of engineering, fabrication, and logistics consistently deliver better outcomes than those chasing the shortest promised delivery date.

In steel construction, predictability protects budgets, and disciplined planning almost always pays for itself.

Reviewed by the Tower Steel Buildings Engineering Team

This article has been reviewed by the Tower Steel Buildings Engineering Team to ensure technical accuracy, alignment with Canadian construction practices, and consistency with real-world steel building manufacturing, scheduling, and erection conditions across Canada.

Our engineering review process reflects decades of combined experience working with commercial developers, agricultural operators, industrial owners, and municipal authorities nationwide.

1. When does steel building lead time officially start?

Steel building lead time typically begins after final engineered drawings are approved, not at contract signing. Fabrication cannot start until structural shows, connection details, and load calculations are finalized and approved.

2. How long are steel building lead times in Canada?

Lead times vary by project complexity and season. Most Canadian steel buildings fall between 6 and 14 weeks after drawing approval, with larger or highly engineered structures requiring additional time.

3. Can lead times affect financing or insurance?

Yes. Extended lead times can impact lender draw schedules, interest carrying costs, and insurance binders. Delays between foundation completion and steel delivery often increase administrative and holding expenses.

4. Do faster lead times always reduce total project cost?

Not necessarily. Accelerated schedules that bypass normal engineering review or quality control often result in erection delays, rework, or missing components. These issues usually cost more than the time saved.

5. How can buyers reduce lead time risk?

Buyers can reduce risk by finalizing design decisions early, avoiding mid-project changes, coordinating foundation schedules with confirmed delivery dates, and working with manufacturers that control both engineering and fabrication.

6. Are Canadian-manufactured steel buildings delivered faster than imported kits?

In many cases, yes. Canadian manufacturing typically offers more predictable lead times, shorter replacement cycles, and faster issue resolution compared to imported steel packages.