Construction risk is not an abstract concept in steel building projects. It is a measurable, predictable set of conditions that influence cost, schedule, safety, and long-term performance. In Canada, where steel buildings must contend with climate extremes, regulatory oversight, and complex coordination between disciplines, unmanaged risk is one of the primary reasons projects experience delays, redesigns, and cost escalation.

Climate data published by Environment and Climate Change Canada influences structural design assumptions and construction planning.

Managing construction risk does not mean eliminating uncertainty. It means identifying where risk typically originates, understanding how it propagates through a project, and making informed decisions early enough to control outcomes rather than react to them.

This article explains how construction risk appears in steel building projects, why it often goes unnoticed until it becomes expensive, and how disciplined planning and coordination reduce exposure without inflating cost.

Who This Article Is For

This article is intended for owners, developers, contractors, and project managers planning permanent steel buildings in Canada where schedule certainty, regulatory approval, and long-term asset performance matter.

It may not apply to temporary structures or lightly engineered enclosures where long-term durability, inspection approval, and lifecycle cost are not critical considerations.

Understanding Construction Risk in Steel Building Projects

Construction risk in steel buildings is rarely caused by steel itself. It is caused by decisions made before steel arrives on site, often long before erection crews are involved.

Risk typically emerges when assumptions replace verification. When site conditions are inferred rather than confirmed. When engineering scope is incomplete. When coordination between trades is deferred. When schedules are driven by optimism rather than prerequisites.

Unlike some construction systems, steel structures are highly precise. They depend on accurate load transfer, alignment, and sequencing. This precision delivers strength and efficiency, but it also means that errors are exposed quickly and visibly.

Managing construction risk begins with recognizing that steel building projects reward preparation far more than acceleration.

The Primary Sources of Construction Risk

While every project is unique, construction risk in steel buildings consistently originates from a small number of sources.

Incomplete or Misaligned Engineering Scope

One of the most significant risk factors is engineering scope that does not align with actual building use or site conditions.

This includes:

- Structural design based on assumed loads rather than confirmed equipment, racking, or crane requirements

- Foundation reactions prepared without finalized steel framing

- Connection design deferred until fabrication

- Erection sequencing not considered during structural design

When engineering scope is incomplete, risk is transferred downstream to permitting, fabrication, or erection where changes are more costly and disruptive.

This is why professional steel building engineering plays a critical role in defining load assumptions, structural behaviour, and long-term performance expectations.

Site Conditions Not Fully Resolved

Steel buildings rely on accurate foundations and stable bearing conditions. Proper foundation design ensures that structural loads are transferred safely into the ground and helps prevent long-term movement and performance issues. Construction risk increases sharply when site realities are not fully addressed before design is finalized.

Common issues include:

- Incomplete geotechnical information

- Frost depth assumptions based on regional averages rather than site specifics

- Drainage paths not clearly defined

- Access constraints not considered for crane setup or delivery

Site-related risks often appear as foundation redesigns, inspection failures, or erection delays rather than immediate structural problems. Careful planning of foundation installation procedures helps reduce inspection failures, alignment issues, and construction delays.

Permitting and Regulatory Assumptions

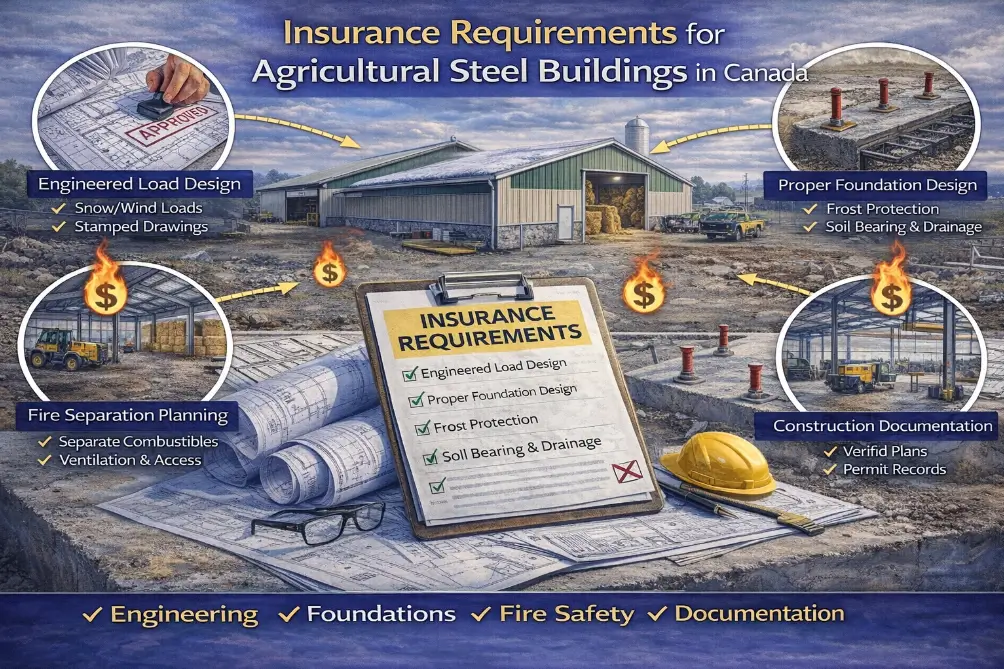

In Canada, regulatory compliance is not uniform across jurisdictions. National requirements such as the National Building Code of Canada establish baseline standards for structural safety and performance. Construction risk increases when projects assume approval rather than confirming requirements early.

Examples include:

- Zoning constraints affecting setbacks or building height

- Fire separation requirements impacting wall design

- Environmental review requirements affecting site work sequencing

- Municipal interpretation differences within the same province

Permitting delays are often treated as administrative issues, but they are a direct construction risk because they affect scheduling, mobilization, and material pricing.

Risk Transfer Versus Risk Management

A common misconception is that construction risk can be transferred entirely through contracts. In practice, risk can be allocated but not eliminated.

When risk is transferred without being managed, it often reappears later in the form of:

- Change orders

- Schedule extensions

- Disputes between trades

- Quality compromises

- Increased insurance scrutiny

These issues frequently arise from design changes and steel building pricing decisions that occur after engineering or fabrication has begun. Effective risk management focuses on reduction, not deflection. It seeks to resolve uncertainty early, when solutions are least expensive and most flexible.

The Role of Early Coordination

Coordination is the most effective risk control tool in steel building projects. Effective coordinating trades during steel building construction prevents conflicts between structural, mechanical, and operational requirements.

Engineering and Foundation Coordination

Steel design and foundation design must evolve together. Separating them increases the likelihood of mismatched reactions, anchor layouts, or load assumptions.

Early coordination allows:

- Foundation sizing to reflect actual steel loads

- Anchor bolt placement to align with framing

- Slab flatness and thickness to support intended use

- Frost protection to be designed once rather than revised later

Trade Coordination Before Fabrication

Many construction risks emerge when mechanical, electrical, or process requirements are introduced after steel fabrication has begun.

Examples include:

- Roof penetrations not coordinated with purlin layout

- Suspended loads added after framing design

- Equipment requiring clearances not reflected in structural drawings

Once steel is fabricated, flexibility is reduced. Coordination before fabrication is not a delay. It is risk prevention.

Schedule Risk and the Illusion of Speed

Construction schedules often focus on erection duration while underestimating prerequisites. Proper steel building site prep ensures foundations, access routes, and grading conditions are ready before erection begins.

In steel building projects, most delays occur before erection begins. Understanding steel building erection timelines and delays helps owners plan sequencing realistically and avoid schedule disruptions.

Common schedule risks include:

- Foundations not ready when steel arrives

- Access routes unsuitable for delivery

- Cranes unable to mobilize due to site conditions

- Inspections delayed due to incomplete documentation

Starting early does not compensate for starting unprepared. Schedule reliability depends on completing prerequisites in the correct sequence.

Financial Risk and Cost Escalation

Construction risk and financial risk are tightly linked.

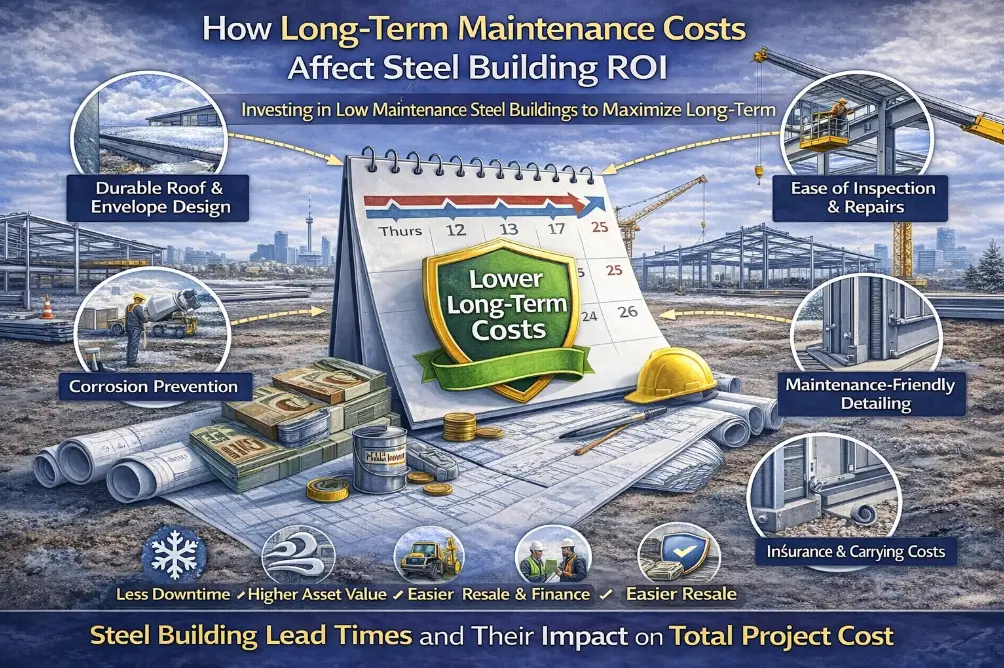

When risk is not managed, cost impacts often appear as:

- Redesign fees

- Re-inspection costs

- Idle labour and equipment

- Extended general conditions

- Financing and insurance adjustments

These costs are rarely visible in initial quotes but can exceed the perceived savings of a lower upfront price.

Many of these expenses originate from hidden costs after signing a steel building contract that were not identified during early planning.

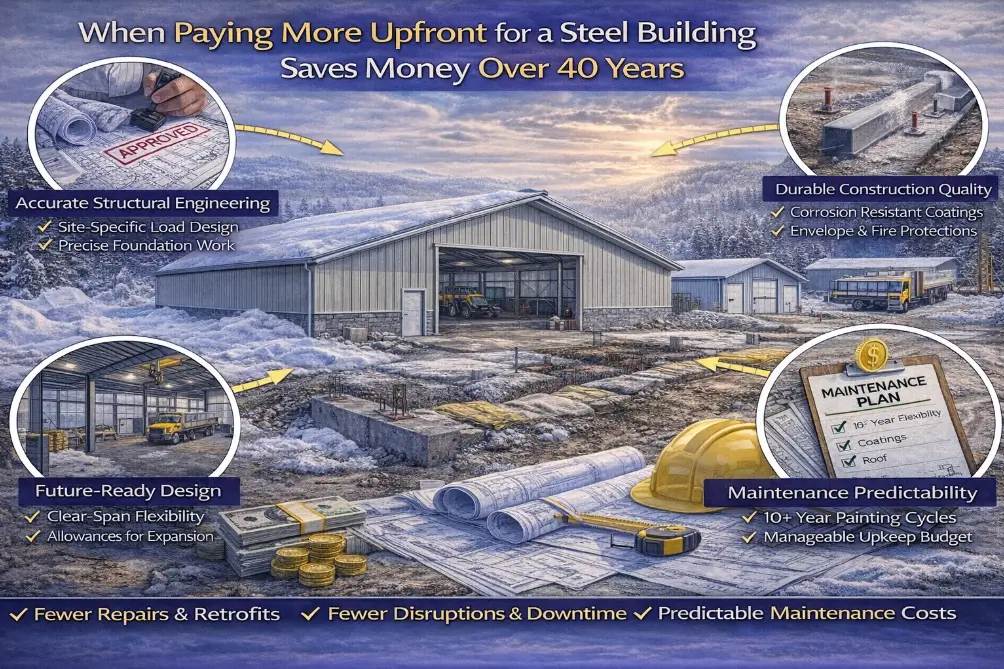

Risk-managed projects tend to experience fewer surprises, even if initial costs appear higher. Over the full project lifecycle, predictability is often less expensive than correction.

Safety Risk as a Construction Variable

Safety is not separate from construction risk. It is a direct outcome of planning quality.

Temporary bracing, erection sequencing, crane access, and site organization all influence safety outcomes. Proper planning of temporary bracing requirements improves structural stability during erection and reduces construction risk.

Projects that rush to erection without resolving:

- Foundation readiness

- Access and laydown planning

- Weather exposure

- Coordination between crews

often experience increased safety incidents and work stoppages. These interruptions affect schedule, cost, and morale.

Managing construction risk includes treating erection safety as an operational requirement, not a procedural afterthought.

Construction Risk and Long-Term Performance

Some construction risks do not appear during the build phase. They emerge years later.

Examples include:

- Misaligned foundations causing differential movement

- Inadequate drainage leading to corrosion or slab damage

- Improper detailing creating condensation issues

- Structural systems not aligned with actual use patterns

These issues increase maintenance costs and reduce asset value. Risk management is not only about getting the building up. It is about ensuring it performs as intended over decades of service.

A Practical Summary of Risk Control

Steel building construction risk is manageable when addressed systematically.

Key principles include:

- Define engineering scope early and fully

- Confirm site conditions rather than assuming them

- Coordinate disciplines before fabrication

- Align schedule with prerequisites, not optimism

- Treat safety and erection planning as design inputs

- View cost through lifecycle impact, not initial price

Projects that follow these principles tend to experience fewer delays, fewer disputes, and more predictable outcomes.

Construction Risk Is a Planning Issue, Not a Steel Issue

Steel buildings are often chosen for their strength, efficiency, and predictability. Those advantages are realized only when construction risk is managed deliberately.

Risk is not reduced by speed or optimism. It is reduced by clarity, coordination, and disciplined decision-making.

In steel construction, the most reliable projects are not the fastest to start. They are the best prepared to proceed.

Reviewed by the Tower Steel Buildings Engineering Team

This article has been reviewed by the Tower Steel Buildings Engineering Team to ensure technical accuracy, alignment with Canadian building practices, and consistency with real-world steel building project execution across Canada.

1. What are the biggest construction risks in steel building projects?

The most common construction risks include incomplete engineering scope, unresolved site conditions, poor coordination between trades, permitting delays, and unrealistic schedules. In steel buildings, these risks often surface early because the system relies on precise foundations, alignment, and sequencing.

2. When does construction risk usually appear in a steel building project?

Most construction risk appears before steel arrives on site. Issues related to foundations, access, approvals, and coordination typically cause more delays and cost escalation than the erection process itself.

3. Who is responsible for managing construction risk on a steel building project?

Construction risk is shared. Owners, designers, engineers, and contractors each influence risk through decisions they control. Risk increases when responsibilities are assumed rather than clearly defined and coordinated early in the project.

4. How does incomplete engineering increase construction risk?

Incomplete engineering can lead to redesigns, permit revisions, fabrication changes, and erection delays. When structural loads, connections, or foundations are not fully coordinated upfront, corrections later become costly and disruptive.

5. Can construction risk be transferred entirely through contracts?

No. Contracts can allocate responsibility, but they cannot eliminate risk. Professional standards from Engineers Canada emphasize verification, accountability, and coordinated design responsibility. Unresolved technical or coordination issues will still affect schedule, cost, and performance regardless of contractual language.

6. How do site conditions affect construction risk in steel buildings?

Steel buildings depend on accurate foundations and stable bearing conditions. Inadequate geotechnical information, incorrect frost depth assumptions, drainage issues, or limited crane access can all create significant construction delays and redesign costs.

7. Why do permitting and inspections increase construction risk?

Permitting and inspections directly affect scheduling. Differences in municipal requirements, review timelines, and interpretation can delay foundation work or erection if assumptions are made instead of confirmed early.

8. How does poor coordination between trades create risk?

When mechanical, electrical, or process requirements are introduced after steel fabrication begins, modifications often require cutting, reinforcement, or redesign. Early coordination reduces these conflicts and protects schedule and warranties.

9. Does faster erection reduce construction risk?

Not necessarily. Speed without preparation increases risk. Steel erection proceeds smoothly only when foundations, access, documentation, and coordination are complete. Preparation determines speed, not the other way around.

10. How does construction risk affect long-term building performance?

Some risks do not appear during construction but emerge years later as maintenance issues, corrosion, settlement, or operational limitations. Managing risk early improves durability, reduces lifecycle costs, and protects asset value.

11. Is managing construction risk worth the upfront effort?

Yes. Projects that invest time in early planning, coordination, and verification typically experience fewer delays, fewer change orders, and more predictable outcomes over the life of the building.