Ontario’s construction industry continues to evolve, and steel has emerged as the backbone of modern infrastructure. Whether it’s a warehouse, commercial facility, or industrial workshop, steel building construction offers unmatched strength, speed, and efficiency.

The process, however, is far more sophisticated than simply assembling panels and frames. From design and engineering to fabrication and erection, each stage requires careful coordination and precision.

Tower Steel Buildings, based in Ontario, has refined this process into a full-service system – offering clients seamless management from the first design draft to a fully completed structure.

This guide walks through every stage of steel building construction in Ontario, explaining what happens behind the scenes and why a turnkey approach delivers better results.

Stage One: Planning and Concept Development

Every successful project begins with clear planning. In this early phase, the client’s vision, site conditions, and budget are translated into technical parameters.

Key steps include:

- Site Evaluation: Assessing the land for grading, drainage, and access.

- Project Scope: Defining the building’s use – warehouse, workshop, office, or agricultural.

- Budget Alignment: Setting realistic expectations based on Ontario steel building costs.

- Design Goals: Identifying functional needs such as clear spans, insulation, or mezzanine levels.

Tower Steel Buildings conducts a site consultation to ensure zoning compliance, setback requirements, and local permit expectations are accounted for before design begins.

This groundwork minimizes costly design revisions later and helps secure faster permit approval.

Stage Two: Design and Engineering

Once the scope and site are approved, the project moves into design and engineering. This phase transforms ideas into certified construction drawings that meet the Ontario Building Code (OBC) and local regulations.

Key components of this stage include:

a. Structural Design

The engineering team calculates loads for snow, wind, and seismic conditions based on the building’s exact location in Ontario. This ensures each frame member is optimized for both strength and cost efficiency.

b. Architectural Layout

Building dimensions, bay spacing, door locations, and interior flow are finalized. Optional elements like insulation systems, skylights, and ventilation are integrated into the plans.

c. Foundation Coordination

Engineers prepare foundation details and anchor bolt plans to match the steel framing system precisely. Coordination between structural and civil engineers ensures long-term stability.

d. Building Code Compliance

All designs are reviewed by Tower Steel’s licensed engineers and stamped for OBC compliance, ready for submission to municipal authorities.

This design process ensures that every element – from base plates to roof panels – fits perfectly during assembly.

Stage Three: Fabrication and Quality Control

After engineering approval, the project transitions into fabrication – the manufacturing of all structural components.

At Tower Steel Buildings’ Ontario manufacturing facility, each part is fabricated using precision CNC machinery for accurate cutting, drilling, and welding.

Typical components include:

- Primary frames (columns, rafters)

- Secondary members (purlins, girts, bracing)

- Roof and wall panels

- Trim, flashing, and accessories

Before shipment, each piece undergoes rigorous quality control, including dimensional verification, coating checks, and alignment testing.

Because everything is prefabricated, there are no on-site surprises – just efficient assembly. This step is what makes steel construction faster and more predictable than traditional building methods.

Stage Four: Delivery and Site Preparation

Once fabrication is complete, materials are delivered directly to the project site.

Before delivery, Tower Steel’s project managers coordinate logistics to align with the foundation and site readiness schedule. Trucks are loaded in sequence to match the erection order, which minimizes handling on-site.

Site preparation typically includes:

- Grading and compacting the soil.

- Pouring the concrete foundation.

- Installing anchor bolts and verifying alignment.

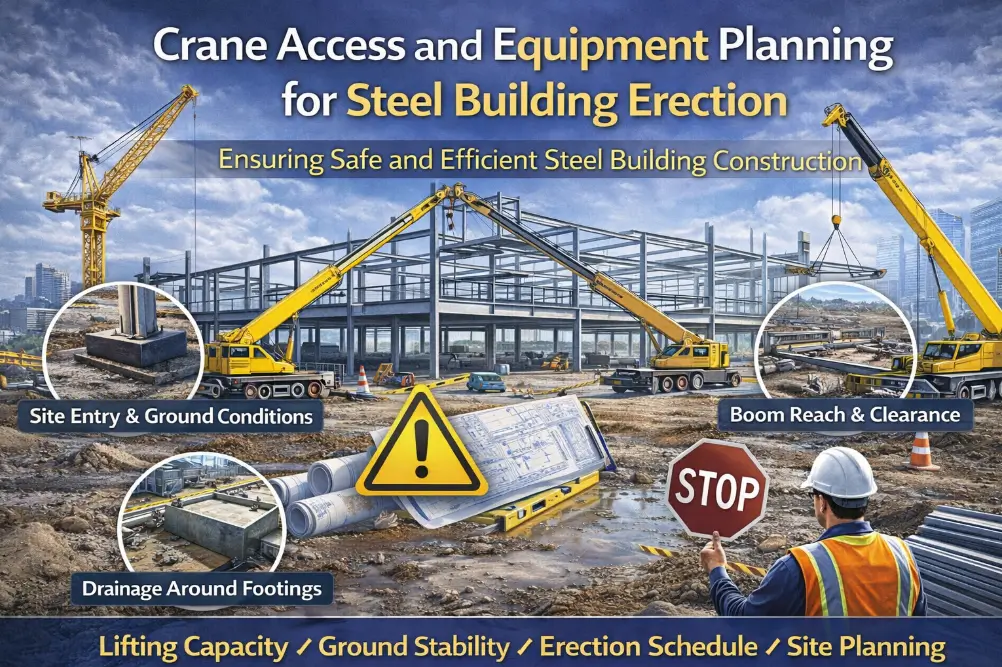

- Preparing access routes for delivery trucks and cranes.

Proper scheduling at this stage ensures the steel erection team can begin work immediately upon material arrival.

Stage Five: Erection and Assembly

The erection phase is where design and planning come to life. Certified crews assemble the steel framework, install wall and roof systems, and complete all fastening and alignment work.

A typical erection sequence includes:

- Erecting main columns and rafters.

- Installing bracing and secondary framing.

- Placing roof purlins and wall girts.

- Installing roof and wall cladding panels.

- Adding insulation, windows, and doors.

- Finalizing trim and flashing details.

Safety is critical during this stage. Tower Steel’s erection crews are trained in fall protection, crane operation, and proper load handling. Each bolt and weld is verified to meet structural design specifications.

By following this structured process, most small-to-medium steel buildings can be erected within a few weeks – far faster than conventional concrete or wood construction.

Stage Six: Finishing and Interior Work

Once the main structure is complete, finishing touches begin. Depending on the project type, this may include:

- Electrical and plumbing installations.

- Insulation and vapour barrier placement.

- Interior partitions and office spaces.

- Concrete floor finishing and polishing.

- Mechanical ventilation systems.

Tower Steel Buildings often collaborates with mechanical and electrical contractors to ensure these systems integrate seamlessly with the steel framework.

For clients who choose a turnkey solution, Tower Steel manages this phase entirely – coordinating trades, scheduling inspections, and ensuring all components align with the engineered design.

Stage Seven: Final Inspection and Handover

Before handover, every building undergoes a comprehensive inspection to verify quality, alignment, and compliance.

Checklist items include:

- Bolt tightening and torque checks.

- Structural alignment verification.

- Door and window operation tests.

- Sealant and flashing review.

- Drainage and slope inspection.

- Municipal inspection sign-off.

Once the structure passes all evaluations, Tower Steel provides the client with a Project Completion Package, which includes as-built drawings, warranty information, and maintenance guidelines.

This documentation ensures transparency and simplifies future modifications or additions.

The Advantages of a Turnkey Steel Construction Partner

Coordinating multiple contractors often leads to communication issues and unexpected costs. By contrast, a single-source construction partner like Tower Steel Buildings offers full accountability from start to finish.

Benefits include:

- Streamlined communication and scheduling.

- Accurate cost control with no hidden extras.

- Faster project delivery.

- Consistent quality through all stages.

- Simplified permit and engineering coordination.

Clients save both time and administrative effort while ensuring their project stays on schedule and within budget.

Tower Steel Buildings’ Integrated Construction System

Tower Steel Buildings’ process is designed for efficiency and precision at every step.

Their integrated system includes:

- In-House Design & Engineering: Certified engineers use advanced CAD and 3D modeling software to optimize structure and cost.

- Fabrication: Controlled Ontario facility ensuring accuracy and consistency.

- Foundation Drawings: Coordination with concrete contractors for perfect bolt placement.

- Delivery & Logistics: Sequenced shipping for smooth on-site assembly.

- Erection Crews: Certified teams following engineered plans and safety standards.

- Project Management: Dedicated supervision from start to finish.

This full-service approach has made Tower Steel Buildings one of Ontario’s most trusted names in prefabricated steel construction.

Example Project: Manufacturing Facility in Mississauga

A manufacturing company in Mississauga needed a 10,000-square-foot production facility with integrated office space.

Tower Steel Buildings handled the entire process – from design to turnkey completion.

Highlights included:

- Custom-engineered frames designed for crane loads.

- Insulated metal wall and roof systems for energy efficiency.

- Foundation design and bolt alignment provided in-house.

- Building erected and finished within 12 weeks.

By managing every phase internally, Tower Steel delivered the facility two months faster than the client’s previous general contractor experience.

Why Steel Construction Leads Ontario’s Future

As Ontario continues to modernize its industrial and commercial infrastructure, steel remains the most efficient and durable choice for construction.

The combination of engineering precision, speed, and low life-cycle cost positions steel as the foundation for sustainable growth.

Turnkey steel construction reduces project risk, eliminates coordination gaps, and provides clients with predictable timelines and transparent pricing.

Whether for manufacturing, logistics, or community facilities, companies across Ontario are choosing Tower Steel Buildings for their proven expertise and commitment to excellence.

Conclusion

From concept to completion, steel building construction in Ontario represents the perfect balance of strength, innovation, and efficiency.

Every phase – planning, design, fabrication, erection, and finishing – plays a critical role in ensuring long-term structural performance and client satisfaction.

With Tower Steel Buildings, Ontario businesses gain more than a supplier. They gain a trusted partner dedicated to delivering projects that meet code, budget, and performance expectations – every single time.

Reviewed by the Tower Steel Buildings Engineering Team

This article has been reviewed by the Tower Steel Buildings Engineering Team to ensure accuracy in construction process details and compliance with Ontario Building Code standards.