Steel building construction is often viewed as a linear process: design, fabricate, erect, and finish. In practice, successful projects depend far more on how well multiple trades are coordinated than on how quickly any single phase moves. Poor coordination is one of the most common reasons steel building projects experience delays, cost overruns, inspection failures, and rework.

In Canada, steel building construction timelines are shaped as much by trade sequencing, inspections, and site readiness as by fabrication or erection speed itself. Coordination is not an administrative task. It is a technical requirement that directly affects cost, schedule, and long-term building performance.

Who This Article Is For

This article is intended for building owners, developers, farmers, fleet operators, and project managers planning permanent steel buildings in Canada where schedule certainty, inspections, and multi-trade coordination matter. It may not apply to temporary storage structures or lightly engineered enclosures where full coordination and inspection requirements are limited.

Why Trade Coordination Matters More in Steel Construction

Steel buildings differ from many other construction systems because they rely on precise load paths, defined connection points, and engineered tolerances. These requirements are governed nationally under the National Building Code of Canada, which establishes engineering and inspection standards for permanent construction. Once steel is erected, changes become more difficult, more expensive, and more visible to inspectors.

Unlike wood framing, steel structures do not tolerate improvisation well. Openings, penetrations, attachments, and service routes must be planned before fabrication, not discovered during installation. When coordination fails, problems surface quickly and often halt progress.

The Trades Involved in a Typical Steel Building Project

A steel building project typically involves coordination between:

- Structural steel engineering and fabrication

- Foundation and concrete contractors

- Steel erection crews

- Mechanical trades

- Electrical trades

- Plumbing and fire protection trades

- Roofing and cladding installers

- Insulation and vapor barrier installers

- Municipal inspectors and third-party reviewers

Each trade impacts the others. Delays or assumptions at any point can cascade through the entire project. This pattern is common when early site planning and sequencing are overlooked, as explained in steel building site preparation.

Where Trade Coordination Commonly Breaks Down

Foundation and Steel Interface

One of the most frequent coordination failures occurs between foundation design and steel reactions. Anchor bolt placement, elevation tolerances, and embedment details must align exactly with the steel design. When foundation work proceeds without confirmed steel reactions, corrections are often required after concrete is poured.

Many of these issues arise from poor alignment between structural loads and footing design, which is why proper steel building foundation design is essential for preventing costly rework.

Envelope and Penetrations

Roof and wall systems require early coordination for vents, ducts, piping, and electrical penetrations. Once cladding or roofing is installed, retrofitting penetrations introduces weatherproofing challenges, inspection review, and warranty exposure.

For example, it is common for structural steel to be erected on schedule, only for mechanical trades to later discover that required roof penetrations or service routes were never coordinated. At that stage, cutting through completed framing or roof assemblies introduces delays, additional inspection review, and potential warranty concerns that could have been avoided through early trade coordination.

Equipment Loads and Attachments

Manufacturing equipment, cranes, lifts, and mezzanines often impose loads that exceed generic assumptions. When these loads are identified late, steel reinforcement or redesign becomes necessary, affecting both schedule and cost.

Late design changes are a major contributor to overruns, which is why understanding how engineering errors increase steel building costs is critical early in planning.

Coordination Is Not Speed

A common misconception is that starting earlier compensates for incomplete coordination. In steel construction, this is rarely true.

Starting fabrication or erection without complete trade coordination often results in stoppages later, when changes are more disruptive. In steel construction, starting early does not compensate for starting unprepared. Coordination determines speed, not the other way around.

Who Is Responsible for Trade Coordination

Responsibility for coordination depends on the project delivery model. It may involve the owner, general contractor, design-build team, or steel supplier. What matters most is not who is named responsible, but whether responsibility is clearly defined and actively managed.

In practice, coordination often fails when each party assumes another is responsible, rather than confirming responsibility contractually and procedurally at the outset.

Clear coordination requires documented scope, confirmed interfaces, and active communication between trades before work begins.

Inspections and Trade Sequencing in Canada

Canadian inspection processes reinforce the need for coordination. Inspectors review not only structural compliance, but also envelope integrity, fire separation continuity, drainage performance, and service penetrations, all of which depend on prior trade coordination.

When trades work out of sequence or without coordination, inspections are delayed or failed. Each failed inspection introduces rebooking delays, administrative costs, and schedule compression that compounds across trades.

How Poor Coordination Increases Project Costs

Coordination failures increase costs through:

- Rework of completed steel or concrete

- Extended equipment rentals and labour downtime

- Additional engineering reviews

- Inspection re-submissions

- Schedule compression costs

- Warranty and performance risk

These costs are rarely visible in initial budgets but often exceed the savings from rushing early phases. Over time, coordination failures also increase lifecycle expense, which is why long-term maintenance costs and steel building ROI depend heavily on early planning accuracy.

Coordination During Steel Erection

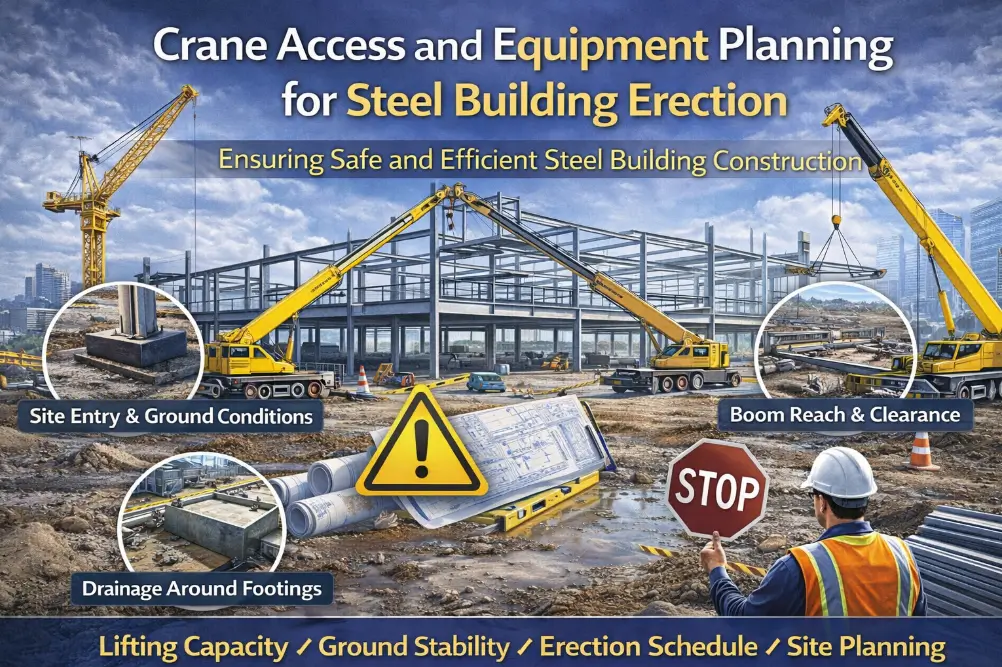

Steel erection is one of the most sensitive phases for coordination. Crane access, sequencing, temporary bracing, and access routes must align with foundation readiness and site conditions.

Poor crane planning is one of the most common erection delays, particularly when crane access and equipment planning for steel building erection are not addressed early.

If other trades are not aligned with erection sequencing, steel crews may be forced to stop, re-sequence, or return later, increasing risk and cost. This frequently occurs when temporary bracing requirements during steel building erection are underestimated during design.

The Role of Pre-Planning and Documentation

Effective coordination depends on:

- Complete engineering documents

- Confirmed foundation drawings

- Clear erection sequencing plans

- Defined penetration locations

- Trade coordination meetings before fabrication

Documentation does not slow projects. It prevents delays later when changes are far more expensive.

Coordination Across Commercial, Agricultural, and Industrial Projects

Trade coordination challenges affect all building types, but the risks increase with building complexity.

- Agricultural buildings often involve future equipment loads and phased installations

- Commercial buildings require careful fire separation and service routing

- Industrial buildings demand strict coordination for machinery, cranes, and utilities

In all cases, early coordination reduces cost and improves long-term performance.

Coordination and Long-Term Building Performance

Poor coordination does not only affect construction schedules. It also impacts long-term performance through:

- Improper load transfer

- Increased maintenance exposure

- Reduced envelope durability

- Service access limitations

Steel buildings perform best when coordination decisions are made early and documented clearly.

Coordinating Trades Is a Management Discipline

Trade coordination is not a software problem or a scheduling exercise. It is a management discipline that requires technical understanding, clear communication, and accountability.

Successful steel building projects treat coordination as a design requirement, not a construction afterthought.

Coordinating Trades in Practice

Organizations with experience delivering steel buildings across Canada recognize that coordination must begin before fabrication and continue through erection and finishing. Integrating engineering, fabrication, and site coordination early helps ensure that steel buildings perform as intended under real operating conditions.

Steel Building Coordination in Summary

- Coordination failures originate before steel arrives on site

- Foundations, access, and approvals control schedules

- Most delays are avoidable with early planning

- Steel buildings reward preparation and penalize assumptions

In steel construction, coordination is not an optional layer added after design. It is the framework that allows engineering, fabrication, and erection to function as a single system. Projects that invest in coordination early experience fewer delays, fewer change orders, and more predictable outcomes across Canadian construction environments.

In steel construction, coordination is not a layer added after design. It is the system that allows the building to function as intended.

Reviewed by the Tower Steel Buildings Engineering Team

This article was reviewed by the Tower Steel Buildings engineering team, drawing on decades of combined experience delivering steel building projects across Canada. The review reflects real-world coordination challenges observed during foundation work, steel erection, trade sequencing, and municipal inspections in commercial, agricultural, and industrial projects.

The intent of this review is to ensure technical accuracy, practical relevance, and alignment with Canadian construction practices, permitting requirements, and site realities.

1. Who is typically responsible for coordinating trades on a steel building project?

Responsibility depends on the project delivery model. In many projects, coordination is led by the general contractor or design-build team. In others, owners or developers retain responsibility for coordinating foundation, mechanical, and electrical trades. What matters most is that coordination responsibility is clearly defined and actively managed, rather than assumed.

2. When should trade coordination begin on a steel building project?

Coordination should begin before fabrication and well before steel erection. Penetrations, equipment loads, service routes, and foundation interfaces should be confirmed during design, not after materials are ordered or steel is erected.

3. Can steel erection proceed if other trades are not ready?

Steel erection can technically proceed, but doing so often increases risk. If penetrations, attachments, or equipment requirements are unresolved, erection may need to stop or be re-sequenced. This commonly results in delays, additional crane time, and rework.

4. How do coordination issues affect inspections in Canada?

Municipal inspectors review not only structural compliance, but also envelope integrity, drainage, fire separation, and service penetrations. Poor coordination often leads to failed inspections, rebooking delays, and additional review cycles that extend project timelines.

5. Are coordination issues more common in certain types of steel buildings?

Coordination challenges increase with building complexity. Manufacturing facilities, fleet maintenance buildings, and commercial projects with multiple services face higher coordination risk than simple storage buildings. Agricultural buildings can also face challenges when future equipment loads are not planned early.

6. Can poor coordination affect long-term building performance?

Yes. Inadequate coordination can lead to compromised load paths, reduced envelope durability, limited service access, and increased maintenance exposure. These issues often appear years after construction, long after initial cost savings are forgotten.