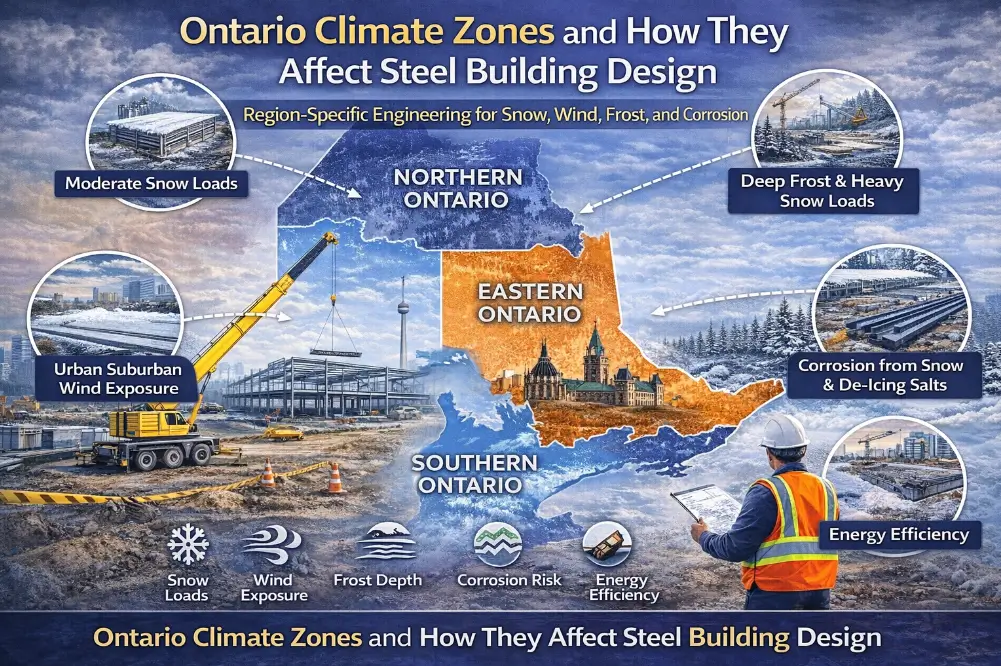

Designing steel buildings in Northern Ontario is not simply a colder version of building elsewhere in the province. The region presents a distinct set of structural, logistical, and regulatory challenges that must be addressed early in the design process. Projects that succeed in Northern Ontario are those planned with climate realism, site access limitations, and long-term performance in mind.

Northern Ontario regions such as Sudbury, Thunder Bay, Timmins, and surrounding remote areas experience conditions that differ significantly from southern Ontario construction environments. Longer winters, deeper frost penetration, heavier snow accumulation, and extended freeze thaw cycles all place additional demands on steel building design and coordination.

While steel construction is well suited to cold climates, Northern Ontario requires a more deliberate approach. Treating these conditions as minor adjustments rather than primary design drivers often leads to redesign, permit delays, and higher long-term costs.

Who This Article Is For

This article is intended for owners, developers, municipalities, and operators planning permanent steel buildings in Northern Ontario where durability, inspection approval, and long-term reliability matter. It may not apply to temporary structures, seasonal storage shelters, or lightly engineered enclosures that do not require full code compliance.

Climate Is the Starting Point, Not an Adjustment

Climate is not a secondary variable in Northern Ontario steel building design. It defines the baseline assumptions for structural loading, foundation design, and construction feasibility.

Snow Loads Are Higher and More Variable

Snow load design is one of the most significant challenges in Northern Ontario. Ground snow loads are higher, and drifting effects are often more severe due to open terrain, wind exposure, and limited natural wind breaks.

Roof geometry, parapets, adjacent structures, and drift zones frequently govern design more than average snow depth. This is why understanding steel building snow load zones across Canada is essential when engineering northern structures for extreme winter conditions. Buildings that appear similar in size and use can require very different structural solutions depending on orientation and exposure.

Designing conservatively in this context does not mean over-engineering. It means accounting accurately for site conditions rather than correcting assumptions later at a higher cost.

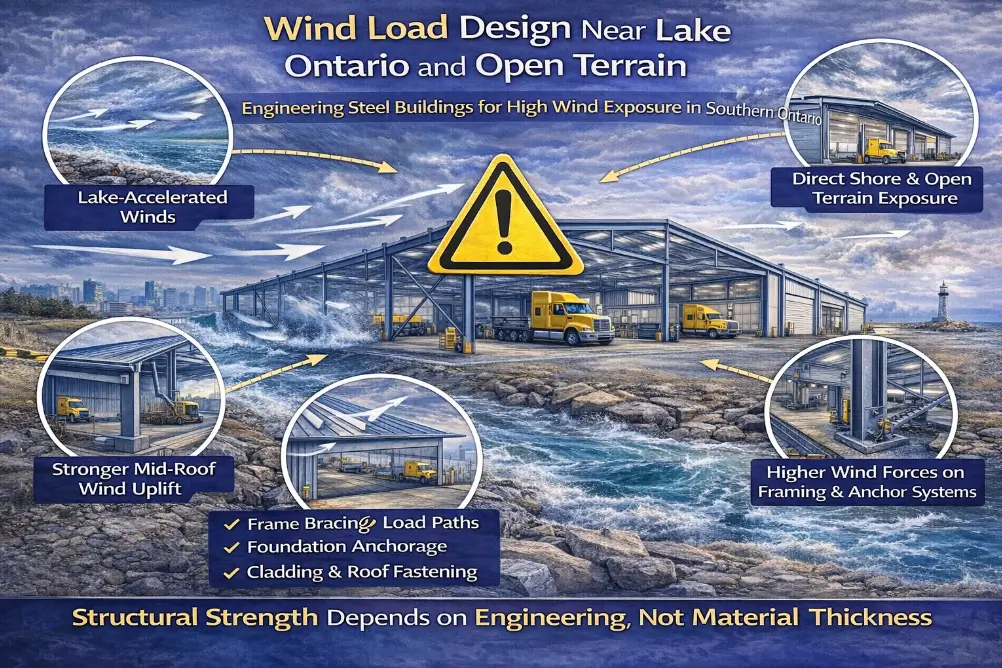

Wind Exposure Is Often Underestimated

Many Northern Ontario sites are located in open or semi-open terrain where wind speeds are higher and surface roughness is lower. This increases lateral load demands on frames, bracing systems, and foundations.

Steel buildings designed using assumptions from sheltered southern locations may not perform adequately when exposed to sustained northern wind pressures. Proper exposure classification and site-specific assessment are essential.

Wind behaviour in open terrain is explored further in wind load design for steel buildings near exposed environments, where sustained pressures govern structural performance.

Foundation Design Is More Complex in Northern Regions

Foundation design is one of the most common sources of cost escalation and delay in Northern Ontario projects.

Frost Depth and Freeze Thaw Effects

Frost depth in Northern Ontario often exceeds that of southern regions by a wide margin. Foundations must be designed to prevent frost heave, differential movement, and long-term settlement.

Shallow foundations that perform well in warmer regions may be unsuitable. Insulated footings, deeper foundations, or specialized frost protection measures are frequently required.

Failure to address frost depth early often leads to foundation redesigns, additional excavation, or delayed inspections. Professional steel building foundation design helps prevent frost-related movement and long-term structural issues in northern climates.

Soil Conditions Vary Widely

Northern Ontario includes areas with bedrock, clay, silts, and mixed soils. Bedrock may be close to the surface in some locations and far below in others. This variability complicates excavation planning, bearing capacity assumptions, and foundation detailing.

Geotechnical investigation is particularly important. Northern projects are especially sensitive to soil conditions and steel building foundations in Canada, where bearing capacity and frost behaviour vary dramatically by location. Assumptions based on nearby projects are often unreliable due to localized soil changes.

Common Early Mistakes in Northern Ontario Steel Building Projects

Many project issues arise not during construction, but during early planning. Common mistakes include:

- Using southern Ontario frost depth assumptions

- Deferring geotechnical investigation until after design

- Scheduling foundation work too late in the season

- Designing steel framing before confirming crane access

- Assuming site access and staging will be “worked out later”

These oversights often trigger redesigns, inspection delays, or winter shutdowns that could have been avoided with early coordination.

Construction Season Limitations Affect Design and Scheduling

Northern Ontario offers a shorter and less predictable construction season. Weather conditions can delay excavation, concrete placement, and steel erection.

Cold Weather Concrete Constraints

Concrete work is sensitive to temperature. In Northern Ontario, cold weather protection measures are often required earlier in the fall and persist later into the spring.

Foundation design and scheduling must account for heating, curing protection, and inspection timing. These factors directly influence cost and feasibility.

Steel Erection Windows Are Narrower

Steel erection in cold, windy, or snowy conditions presents safety and productivity challenges. Ice accumulation, frozen ground, and limited daylight hours can slow progress.

Design decisions that simplify erection, reduce on-site welding, and minimize rehandling are especially valuable in northern projects.

Logistics and Access Are Design Constraints

Northern Ontario projects frequently involve remote or semi-remote sites where logistics play a major role.

Transportation and Delivery Planning

Steel components must be designed with transportation constraints in mind. Oversized members, complex assemblies, or non-standard shipping requirements can increase cost and risk.

Delivery schedules must also account for weather disruptions, road conditions, and limited staging space.

Crane Access and Site Preparation

Crane access is often constrained by terrain, weather, and site layout. Design assumptions should reflect realistic erection sequencing and equipment access.

Poor coordination between structural design and site logistics is a common cause of erection delays once steel arrives on site. Many of these delays are detailed in steel building erection timelines and what actually slows projects down.

Regulatory and Inspection Expectations Remain Strict

Despite the remote nature of many northern sites, regulatory expectations remain unchanged. Buildings must comply with the Ontario Building Code and applicable CSA standards.

These structural design requirements are rooted in the National Building Code of Canada, which establishes snow, wind, and safety load standards nationwide.

While the Ontario Building Code establishes baseline requirements, climate-related design values are applied on a site-specific basis using local reference data.

Municipal inspectors will not approve foundations or structures where frost protection, drainage, or load assumptions are unclear, regardless of location.

Durability and Long-Term Performance Matter More

Buildings in Northern Ontario are exposed to harsher environmental conditions throughout their service life. Durability failures rarely appear immediately, but they compound over years through corrosion, condensation, and escalating maintenance requirements.

Corrosion Protection and Coatings

Cold temperatures, snow retention, and moisture exposure can accelerate corrosion if protective systems are inadequate. Coating selection should reflect environmental exposure, not just initial cost.

Thermal Performance and Condensation Control

Temperature differentials increase the risk of condensation within steel buildings. Proper insulation design, vapour control, and ventilation are essential to prevent long-term damage.

Ignoring these factors can reduce building lifespan and increase operating costs.

Insurance and Lifecycle Considerations

Climate-appropriate design reduces insurance scrutiny and long-term maintenance exposure. Insurers increasingly assess whether buildings are engineered for actual site conditions rather than minimum assumptions.

Buildings designed specifically for Northern Ontario conditions typically experience fewer claims and more predictable lifecycle performance.

When Northern Ontario Design Is Done Well

Successful steel building projects in Northern Ontario share common traits:

- Site-specific climate data is incorporated early

- Foundation and superstructure design are coordinated

- Logistics and crane access are planned realistically

- Construction season limitations are respected

- Long-term performance is prioritized over short-term savings

Organizations such as Tower Steel Buildings apply this approach by integrating engineering, fabrication, and site coordination early, ensuring steel buildings perform as intended under real northern conditions.

Final Perspective

Steel buildings perform exceptionally well in Northern Ontario when designed correctly. Most problems arise not from steel itself, but from assumptions carried over from milder regions.

Northern Ontario demands deliberate engineering, realistic scheduling, and early coordination. Projects that respect these realities experience smoother approvals, fewer delays, and stronger long-term performance. Early coordination around climate data is also critical in Ontario climate zones and steel building design considerations.

In Northern Ontario steel construction, preparation is not a luxury. It is the difference between predictable performance and persistent problems.

Reviewed by the Tower Steel Buildings Engineering Team

This article has been reviewed by the Tower Steel Buildings engineering team to ensure technical accuracy, alignment with Canadian building practices, and consistency with real-world design, permitting, and construction conditions across Northern Ontario. The insights reflect practical experience with steel building projects in cold climates, remote regions, and inspection-driven environments.

1. How is designing steel buildings in Northern Ontario different from southern Ontario?

Northern Ontario projects must account for higher snow loads, deeper frost penetration, longer freeze periods, and more limited construction seasons. These factors directly affect structural design, foundation depth, scheduling, and long-term durability.

2. Does conservative design in Northern Ontario mean higher costs?

Not necessarily. Conservative design in Northern Ontario means accurate design based on real site conditions. This approach often reduces overall project cost by avoiding redesigns, foundation corrections, and delays caused by incorrect assumptions.

3. Why is geotechnical investigation more important in Northern Ontario?

Soil conditions in Northern Ontario vary widely, including bedrock, clay, and mixed soils. Early geotechnical investigation helps ensure foundations are designed correctly and prevents costly changes once construction begins.

4. Are steel buildings suitable for extreme cold climates?

Yes. Steel buildings perform very well in cold climates when properly designed. The key is addressing snow loads, wind exposure, frost protection, insulation, and condensation control during the design stage.

5. How do shorter construction seasons affect steel building projects?

Shorter construction seasons require careful scheduling of excavation, concrete work, and steel erection. Designs that simplify erection and account for weather limitations help keep projects on track.

6. Do Northern Ontario steel buildings face stricter inspections?

Inspection standards are consistent across Ontario. However, inspectors in Northern Ontario pay close attention to frost protection, drainage, load assumptions, and site readiness due to the higher risk of climate-related failures.