Design changes are one of the most common reasons steel building projects exceed their original budget. In most cases, the cost increase does not come from material price spikes or contractor behaviour. It comes from decisions made after pricing assumptions are already in motion.

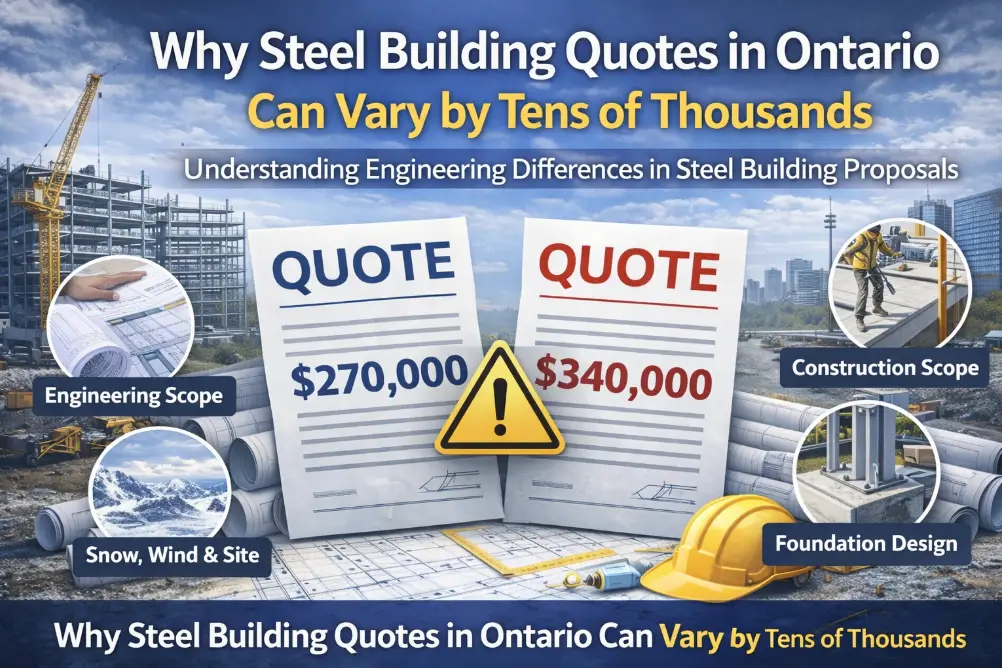

For steel buildings in Canada, steel building pricing is directly tied to engineering assumptions, manufacturing scope, and coordination timing. Even small changes can ripple through design, fabrication, foundations, and erection sequencing.

Understanding how and when design changes affect steel building pricing allows buyers to make informed decisions early and avoid avoidable cost escalation later.

This guide explains where design changes create cost impacts, why those impacts occur, and how experienced project planning reduces exposure without restricting flexibility.

Why Steel Building Pricing Is Design-Driven

Steel building pricing is not based on square footage alone. It is the result of a fully engineered system where each component is sized, coordinated, and fabricated to match a defined set of parameters.

Those parameters include:

- Building dimensions and clear spans

- Roof slope and geometry

- Snow, wind, and seismic loads

- Wall heights and interior clearance needs

- Door, opening, and crane loads

- Insulation systems and thermal performance

- Foundation reactions and anchor layouts

When any of these parameters change, the pricing model must change with them.

Unlike modular products, steel buildings are engineered systems. Design drives material weight, connection detailing, fabrication time, and erection sequencing. That is why design stability matters more than most buyers expect.

Early Design Changes vs Late Design Changes

Not all design changes carry the same cost impact. Timing matters more than the change itself.

Early-Stage Design Adjustments

Changes made before engineering is finalized usually have limited cost impact. At this stage, adjustments affect calculations rather than manufactured components.

Examples include:

- Minor building length or width adjustments

- Door size revisions before framing is finalized

- Roof slope changes before member sizing

- Wall height adjustments prior to foundation design

When these changes happen early, the cost difference is often marginal and predictable.

Late-Stage Design Changes

Changes introduced after engineering, detailing, or fabrication begins have far greater cost consequences.

Examples include:

- Increasing clear span after frames are designed

- Adding crane loads after columns are sized

- Relocating large openings after wall girts are detailed

- Changing insulation systems after panel procurement

- Adjusting building height after foundation drawings are issued

At this point, changes can trigger reengineering, scrap material, production delays, and coordination conflicts. Pricing impact escalates quickly.

Structural Changes and Their Cost Effects

Some design changes affect pricing more than others because they alter the primary structural system.

Clear Span Increases

Increasing clear span often requires heavier frames, deeper rafters, and stronger connections. Even a modest span increase can significantly raise steel tonnage and fabrication complexity.

This also affects:

- Foundation reactions

- Anchor bolt sizing

- Erection equipment requirements

Clear span changes are among the highest-impact pricing adjustments in steel buildings.

Roof Slope and Geometry

Changing roof slope alters load distribution, frame geometry, and purlin design. Steeper slopes may reduce snow accumulation in some cases, but they often increase material quantity and fabrication complexity.

Roof geometry changes can also impact:

- Panel systems

- Bracing layouts

- Drainage and snow drift behavior

Column Height and Interior Clearance

Increasing wall height increases column size, bracing requirements, and foundation loads. Clearance changes for forklifts, racking and forklift clearance, or equipment often require stronger framing and larger footings.

Height changes are rarely isolated. They cascade into multiple design elements.

Architectural Changes That Affect Pricing

Not all cost impacts come from structural steel. Architectural and functional changes can also influence pricing.

Door and Opening Revisions

Large doors require additional framing, reinforced headers, and bracing modifications. Changing door size or location after detailing can require redesign of entire wall bays.

This affects:

- Material usage

- Fabrication sequencing

- Erection order

Insulation and Thermal Performance Upgrades

Higher insulation values increase material costs and may require deeper girts or modified wall assemblies. Roof insulation changes can alter purlin spacing and load assumptions.

Thermal upgrades should be finalized early to avoid redesign costs.

Interior Build-Out and Future-Proofing

Adding mezzanines, partitions, or future expansion allowances later in the process often costs more than planning for them upfront. Designing for future loads is typically more economical than retrofitting after fabrication.

Foundation Design Changes and Cost Exposure

Steel building pricing is closely linked to foundation design. Changes to the superstructure often force changes to the foundation.

Examples include:

- Increased column loads requiring larger footings

- Revised anchor bolt layouts

- Additional frost protection

- Slab thickening for higher point loads

Foundation redesign affects engineering fees, concrete quantities, and inspection timelines. These costs compound when changes occur after permits are issued.

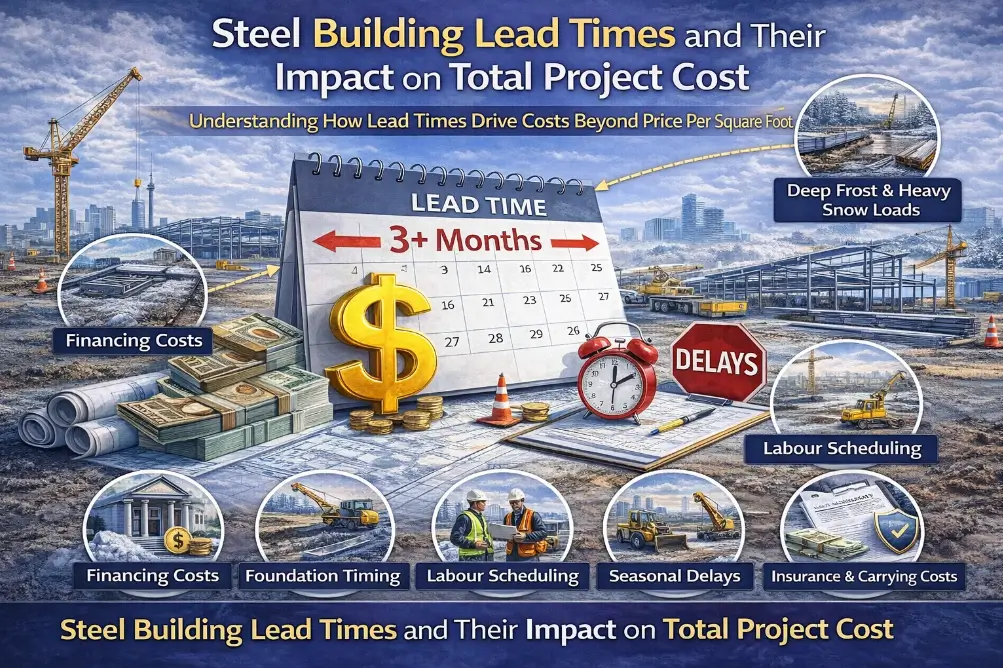

Coordination Costs and Schedule Impacts

Design changes do not only affect materials. They affect coordination.

Late changes often lead to:

- Reissued drawings

- Permit amendments

- Fabrication delays

- Erection rescheduling

- Extended equipment rentals

Schedule disruptions create indirect costs that are not always visible in initial change orders. Carrying costs, labour inefficiencies, and lost operational time often exceed material cost differences.

Who Typically Bears the Cost of Design Changes

In most steel building projects, the cost responsibility follows the timing and origin of the change.

- Owner-initiated changes typically result in price adjustments

- Code-driven changes identified during review may require shared coordination

- Errors or omissions by consultants depend on contractual responsibility

Clear communication and early design coordination reduce disputes and protect project budgets.

Why Accurate Early Design Costs Less Than Correction

Over-engineering increases upfront cost. Under-engineering increases downstream cost. Accurate engineering minimizes both.

Canadian building codes establish minimum acceptable performance, not optimal material efficiency. The most cost-effective steel building designs are those that match loads, usage, and site conditions precisely without unnecessary conservatism or risky assumptions.

Accuracy costs less than correction.

How Experienced Planning Reduces Pricing Volatility

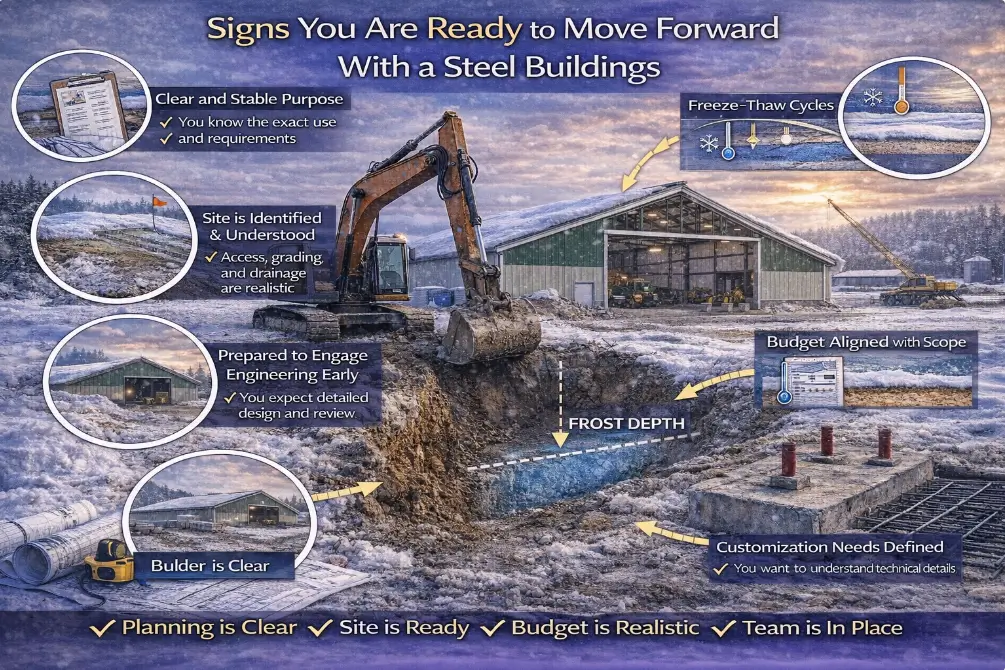

Projects with stable pricing typically share common traits:

- Clear functional requirements defined early

- Coordination between owner, engineer, and building supplier

- Realistic allowance for future expansion

- Early consideration of equipment, racking, and loads

- Site conditions reviewed before final design

Steel building pricing is predictable when design intent is stable.

Design Changes Are Not the Enemy. Unplanned Changes Are.

Design flexibility is one of the strengths of steel buildings. The key is knowing when flexibility is inexpensive and when it becomes costly.

Most pricing surprises are not caused by bad decisions. They are caused by late decisions.

Understanding how design changes impact steel building pricing allows buyers to protect budgets while still achieving the building they need.

Reviewed by the Tower Steel Buildings Engineering Team

This article has been reviewed by the Tower Steel Buildings Engineering Team to confirm technical accuracy, real-world relevance, and alignment with Canadian steel building design, manufacturing, and construction practices.

The review reflects hands-on experience with pricing impacts caused by design changes across commercial, industrial, agricultural, and specialty steel building projects throughout Canada. All scenarios discussed are based on common field conditions, engineering workflows, and fabrication realities.

1. Do small design changes really affect steel building pricing?

Yes. Even minor changes can affect engineering calculations, material quantities, connection details, or fabrication sequencing. While early-stage changes are usually manageable, late-stage adjustments often trigger redesign and rework that increase costs.

2. When do steel building lead times officially begin?

Lead times typically begin only after final engineered drawings are approved, not at contract signing. Design changes made before approval usually have limited pricing impact compared to changes introduced after fabrication has started.

3. Who usually pays for design changes on a steel building project?

In most cases, owner-requested design changes result in price adjustments. Changes driven by code compliance, site conditions, or coordination issues may involve shared responsibility depending on contract terms and timing.

4. Can design changes affect foundation costs as well?

Yes. Changes to the steel structure often alter column reactions and load paths, which can require larger footings, revised reinforcement, or updated anchor layouts. Foundation redesign adds both material and engineering costs.

5. Are design changes more expensive for steel buildings than other systems?

Steel buildings are highly engineered systems. Standards such as CSA A660 influence quality control, manufacturing discipline, and pricing stability. While they offer precision and efficiency, that precision means changes propagate quickly through the design. This makes timing and coordination especially important for cost control.

6. How can buyers reduce the risk of pricing increases from design changes?

Defining functional requirements early, coordinating equipment and clearance needs upfront, and allowing engineers to design accurately from the start reduces the need for late-stage changes. Stable design intent leads to more predictable pricing.

7. Is it better to slightly over-design a building to avoid changes later?

Not necessarily. Over-engineering increases upfront cost without guaranteeing future flexibility. Accurate, well-coordinated design usually delivers better long-term value than either over-designing or under-designing.