Building with steel is one of the most efficient ways to create a durable, low-maintenance structure in Ontario’s climate. Yet even the strongest building starts with careful planning. Whether you are constructing a garage, warehouse, or manufacturing facility, success depends on following a logical sequence-from early concept to final inspection.

This expert guide breaks down how to plan a steel building project in Ontario from start to finish. It is based on the proven workflow that Tower Steel Buildings uses across the province to deliver safe, code-compliant, and cost-effective results.

Define Your Project Goals and Requirements

Every project begins with a clear understanding of purpose and performance. Take time to define what your building must achieve and what constraints exist.

Clarify your goals

- How will the building be used-storage, workshop, commercial, or mixed use?

- What clear height, span, and layout are needed for your operations?

- Will it be heated, insulated, or left unconditioned?

- How much floor area and door access do you need for equipment or vehicles?

Establish key constraints

- Zoning limits, property setbacks, and height restrictions

- Site conditions such as slope, drainage, and soil bearing capacity

- Budget range and available utilities (hydro, gas, water, sewer)

Documenting these requirements early provides a design brief that your engineering team can turn into an accurate Ontario prefab design and cost estimate.

Develop a Realistic Budget

Your budget should account for much more than the steel package. Include all project costs from land preparation to final occupancy.

Typical categories

- Site clearing, grading, and foundation work

- Steel structure, cladding, doors, and windows

- Insulation, vapor barriers, and interior finishes

- Mechanical, electrical, and plumbing systems

- Permits, engineering, and municipal fees

- Erection labour and equipment rental

- Contingency allowance for unforeseen conditions

A detailed budget helps prevent mid-project delays and ensures that financing aligns with actual timelines. Tower Steel Buildings provides transparent, itemized quotes tied to design drawings-not generic allowances-so you know exactly what is included.

Evaluate and Prepare Your Site

Before design begins, assess your site to confirm it can support your building safely and efficiently.

Site evaluation checklist

- Soil testing (geotechnical report) for bearing capacity and frost depth

- Survey to establish property lines and legal access

- Drainage review to plan swales, ditches, or storm connections

- Utility mapping for hydro, water, and gas locations

- Driveway and turnaround design for trucks or equipment

Good preparation now avoids expensive excavation changes later. Many municipalities in Ontario also require a grading plan as part of the permit application.

Engage an Experienced Steel Building Partner

Choosing the right manufacturer and engineer is the most important decision you will make. Work with a company that designs, fabricates, and supplies steel structures in compliance with Ontario Building Code and CSA standards.

Look for

- Ontario-licensed engineers who seal structural drawings

- In-house design and detailing team for faster turnaround

- Proven track record with similar building types

- Local fabrication or delivery capability

- Transparent communication and project documentation

Tower Steel Buildings meets these criteria through its Ontario-based engineering and manufacturing operation, giving clients full accountability from design through installation.

Concept Design and Engineering

With requirements defined, the engineering phase begins. This is where ideas become detailed, code-compliant drawings.

Engineering tasks include

- Load analysis: snow, wind, seismic, and occupancy loads

- Frame design: rigid, multi-span, or hybrid systems

- Foundation sizing based on soil data and reactions

- Layout optimization for door placement, workflow, and efficiency

- Envelope design: insulation type, wall and roof panels, vapor barrier strategy

Outcome:

Engineer-stamped structural and foundation drawings ready for municipal submission. Tower Steel’s engineers use advanced 3D modelling software to ensure precision and seamless coordination between analysis and fabrication.

Obtain Permits and Approvals

In Ontario, nearly all new buildings require a municipal building permit. Each municipality has its own forms and timelines, but most follow similar steps.

Permit submission package

- Application form and fee

- Site plan and property survey

- Engineer-stamped structural and foundation drawings

- Energy compliance summary (if heated or cooled)

- Drainage or grading plan where required

Processing typically takes three to eight weeks depending on the municipality and complexity. Starting early avoids schedule bottlenecks later in your steel project schedule Ontario.

Finalize Contracts and Schedule Fabrication

Once permits are in hand, finalize your purchase order or construction contract. Confirm lead times for manufacturing and delivery.

Checklist before fabrication

- Approve final drawings and specifications

- Review colour selections and door configurations

- Confirm insulation, liner panels, and accessories

- Verify foundation pour dates and anchor bolt templates

- Align delivery with on-site readiness

Fabrication of pre-engineered components usually takes four to six weeks. During this stage, Tower Steel Buildings’ production team runs quality checks on each frame and panel to ensure perfect fit on site.

Prepare the Foundation and Utilities

While steel components are in production, your site crew can proceed with groundwork and concrete.

Foundation tasks

- Excavation to proper depth and soil bearing

- Footings and piers formed and reinforced

- Anchor bolts set with templates provided by Tower Steel

- Slab reinforcement, vapor barrier, and pour sequence

- Underground utilities installed before slab pour

A precise foundation is vital; small errors in anchor bolt layout can delay erection. Always have the engineer verify placement before concrete is poured.

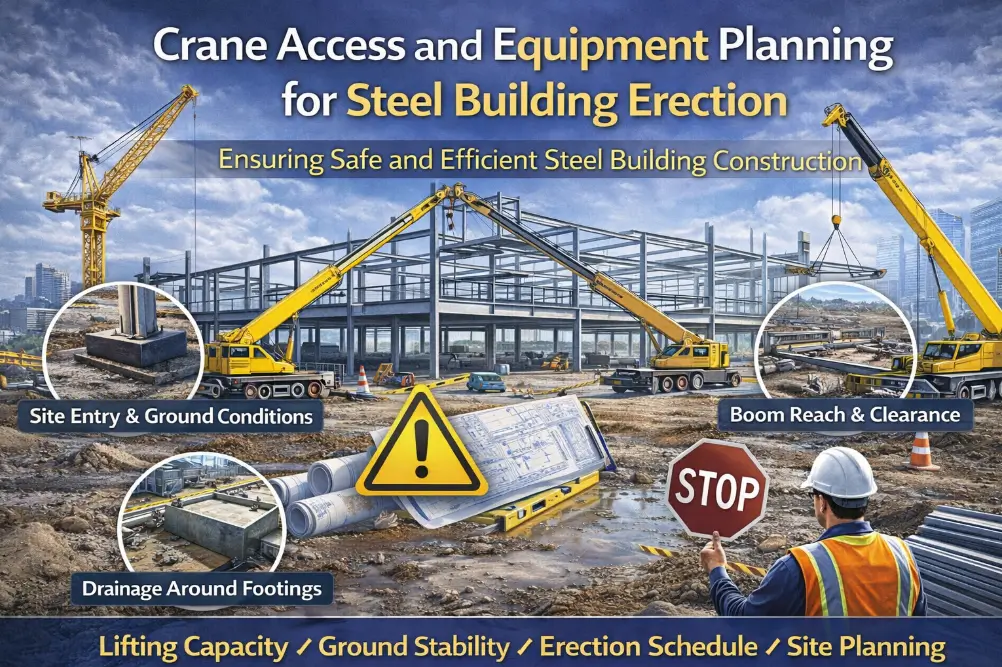

Delivery and Material Handling

Steel buildings are delivered as labelled packages ready for assembly. Proper handling keeps components safe and speeds up erection.

Delivery checklist

- Clear access route for long trailers and cranes

- Flat, dry lay-down area near the foundation

- Forklift or telehandler for unloading

- Secure storage for panels and fasteners away from standing water

Tower Steel Buildings coordinates delivery directly from its Ontario facility and provides an unloading plan that matches the erection sequence.

Erection and On-Site Assembly

This phase turns drawings into a finished structure. Erection time varies by building size but is generally 30–50 percent faster than conventional framing.

Steps in assembly

- Position anchor bolts and base plates.

- Erect main frames and temporary bracing.

- Install purlins, girts, and secondary framing.

- Add roof and wall panels, fasteners, and trim.

- Set doors, windows, and accessories.

- Complete insulation and interior liner panels.

- Finish flashings and sealant details.

Safety first: follow all Ontario construction regulations and manufacturer guidelines. Tower Steel Buildings can connect clients with experienced erection crews who specialize in pre-engineered systems.

Interior Work and Systems

Once the shell is closed in, mechanical and electrical trades can begin. Coordination here ensures that services integrate smoothly with the structure.

Interior sequence

- Heating or ventilation systems

- Lighting and power distribution

- Plumbing and drains (if required)

- Interior partitions or office framing

- Finishes, painting, and flooring

Plan these trades in your Ontario construction planning schedule to avoid conflicts and delays.

Inspections and Quality Assurance

Municipal inspectors will check key stages to verify compliance with permits and code.

Typical inspections

- Footings before concrete pour

- Anchor bolt placement

- Structural framing

- Insulation and vapor barrier

- Final occupancy inspection

Keep all approved drawings and shop prints on site. Tower Steel Buildings’ engineering team provides letters of review or field reports when required to close permits smoothly.

Handover and Closeout

After completion, gather all documentation and warranties. This package confirms compliance and simplifies future maintenance.

Closeout items

- As-built drawings showing field revisions

- Material warranties and paint finish data

- Maintenance instructions for cladding and doors

- Engineer’s completion letter (if requested by the municipality)

Proper documentation protects your investment and helps maintain resale value.

Post-Construction Maintenance Plan

Steel buildings require minimal maintenance, but a routine plan extends service life and preserves appearance.

Annual tasks

- Inspect roof fasteners and sealants for tightness and wear

- Clear debris from gutters and downspouts

- Wash cladding in spring to remove road salt

- Check insulation and vapor barrier in heated spaces for moisture

- Touch up paint where mechanical damage occurred

With these simple checks, your building can remain functional and attractive for fifty years or more.

Realistic Project Timeline for Ontario

A well-planned project follows a predictable schedule. Average durations vary, but this outline helps you estimate milestones.

| Phase | Typical Duration |

| Concept & Budget | 2–3 weeks |

| Engineering & Permitting | 5–10 weeks |

| Fabrication | 4–6 weeks |

| Foundation & Site Prep | 3–5 weeks |

| Erection | 3–6 weeks |

| Interior & Finishing | 2–4 weeks |

| Total Project Window | 4–6 months |

Factors such as municipal review speed, winter weather, and site complexity may adjust this timeline, but consistent communication with your engineer keeps progress on track.

Common Planning Mistakes to Avoid

- Starting design before confirming zoning and setbacks

- Underestimating site preparation costs

- Ignoring permit timelines in scheduling

- Ordering materials before engineering is finalized

- Neglecting snow-drift detailing on multi-level roofs

- Failing to plan for future expansion or utilities

Early coordination and clear documentation prevent these issues and protect your investment.

Tower Steel Buildings – Ontario’s Turnkey Project Partner

With decades of experience, Tower Steel Buildings provides a fully integrated process that eliminates guesswork.

What clients gain

- Local engineering stamped by Ontario-licensed professionals

- In-house design drawings and fabrication control

- Permit assistance and municipal coordination

- Pre-engineered kits that simplify scheduling

- Reliable delivery across Ontario

From concept sketches to final inspection, Tower Steel keeps every stage connected and accountable.

Reviewed by the Tower Steel Buildings Engineering Team

This guide was reviewed by the Tower Steel Buildings Engineering Team, ensuring all planning steps align with Ontario code requirements and current construction practices.

How early should I start planning my steel building project?

Begin at least six months before you want construction to start. This allows time for engineering, permitting, and site work.

Do I need a building permit for a small garage?

Yes. Ontario municipalities require permits for almost all new structures, regardless of size.

How long does it take to get a quote?

Tower Steel Buildings typically provides detailed quotes within five business days once site and design information are available.

Can I make changes after fabrication starts?

Minor changes are possible, but major structural revisions may delay delivery. Always finalize design drawings before approval.

Does Tower Steel handle installation?

Tower Steel supplies engineered buildings and can recommend trusted erection contractors for projects throughout Ontario.