Loading docks are one of the most operationally critical and most underestimated components of a steel warehouse building. While they occupy a relatively small portion of the footprint, dock design directly affects throughput, safety, labour efficiency, equipment lifespan, and long-term maintenance cost.

In Canadian warehouse projects, dock performance is shaped not only by truck traffic and material flow, but also by climate, frost depth, snow management, and inspection requirements. Poor dock design rarely fails immediately. Instead, it creates daily friction that compounds over time through delays, damage, and operational inefficiencies.

In Canada, steel warehouse performance is influenced as much by permitting, inspections, climate exposure, and seasonal construction realities as by structural capacity alone. Structural and operational requirements are guided by the National Building Code of Canada, which establishes baseline performance standards for safety and durability.

Who This Article Is For

This article is intended for owners, developers, and operators planning permanent steel warehouse buildings where logistics efficiency, safety, and durability matter. Many of these operational principles are directly influenced by how modern steel warehouse buildings are designed, engineered, and constructed for Canadian logistics environments.

It is especially relevant for distribution centres, manufacturing warehouses, cold storage facilities, and regional logistics hubs.

It may not apply to temporary storage structures or lightly used loading areas with minimal truck traffic.

Dock Design Intensity Should Match How the Building Is Used

Not all loading docks serve the same function, and dock design requirements should scale with how the facility operates.

In practice, docks generally fall into broad use categories such as:

- High-throughput distribution centres with constant trailer turnover

- Manufacturing facilities with intermittent loading and unloading

- Cold storage operations with environmental separation requirements

- Mixed-use facilities combining shipping, receiving, and internal production

A dock designed for occasional loading may technically function in a high-volume environment, but it will introduce congestion, safety risk, and accelerated wear. Dock design should reflect how the building is actually used, not just how it looks on a site plan.

Why Loading Dock Design Matters More Than Most Owners Expect

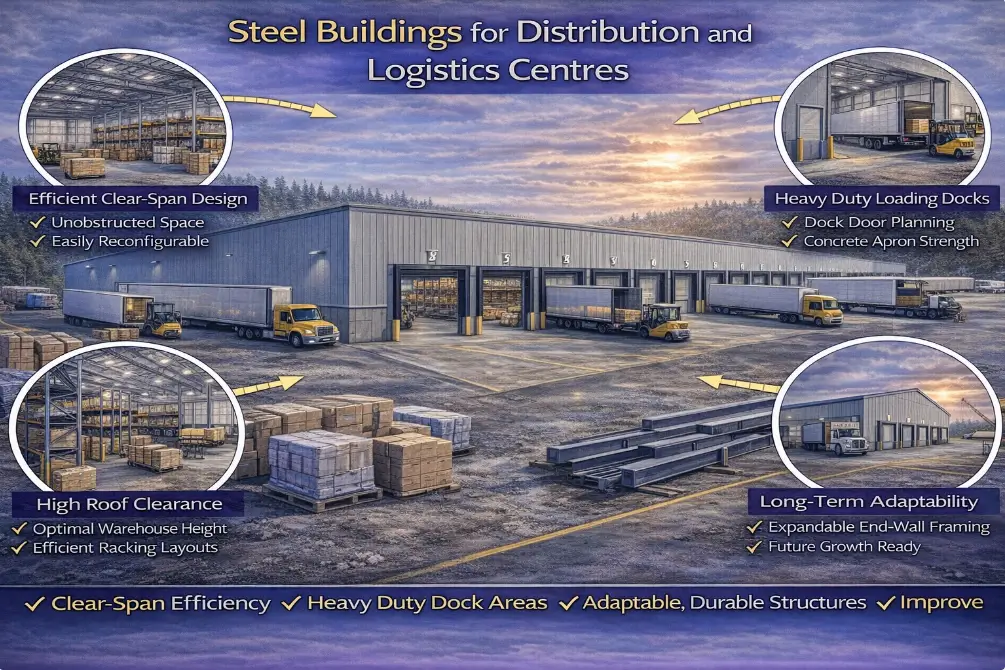

Loading docks are where buildings meet vehicles, people, and schedules. This interface is especially critical in steel buildings for distribution and logistics centres, where dock performance directly determines throughput efficiency. Every inefficiency at the dock multiplies across shifts, trucks, and years of operation.

In steel warehouse buildings, dock design affects:

- Truck turn times and congestion

- Worker safety and ergonomics

- Damage to doors, levelers, and trailers

- Energy loss and moisture intrusion

- Snow, ice, and drainage management

- Long-term slab and foundation performance

Because steel buildings rely on precise structural coordination, dock elements must be integrated into the building design early rather than treated as accessories added later.

How Loading Docks Integrate With Steel Warehouse Structures

Steel warehouse buildings transfer loads through frames, foundations, and slabs that must accommodate dock openings without compromising structural performance. Proper structural detailing also supports structural redundancy and safety in steel building design, ensuring performance even under localized stress.

Dock design affects the building through:

- Large wall openings that influence lateral bracing and load paths

- Dock equipment that introduces concentrated and dynamic loads

- Apron slabs and dock pits exposed to frost and water

- Canopies and seals that affect snow drift and wind exposure

Performance in these areas depends heavily on soil conditions for steel building foundations in Canada, which influence frost heave and long-term settlement behaviour. In Canadian climates, these interactions must be engineered deliberately rather than assumed.

Regional climate data published by Environment and Climate Change Canada informs snow, temperature, and weather exposure assumptions.

Dock Positioning and Building Layout

Relationship to Interior Workflow

Dock placement should align with interior material flow rather than site convenience alone. Poor alignment increases forklift travel, congestion, and safety conflicts.

Effective layouts consider:

- Racking orientation and aisle geometry

- Forklift turning radii and travel distances

- Separation of inbound and outbound movements

- Cross-dock versus storage-based operations

Steel buildings allow long clear spans, but that flexibility only delivers value when dock placement supports real operational patterns.

Exterior Circulation and Yard Geometry

Dock efficiency depends on exterior truck movement as much as interior layout.

Common issues include:

- Insufficient trailer depth at dock faces

- Conflicts between dock traffic and parking or access roads

- Inadequate turning radii for longer trailers

- Poor snow storage planning near dock aprons

These problems are expensive to correct once foundations and slabs are complete.

Dock Door Spacing and Bay Configuration

Door Width and Height

Dock doors must reflect the actual trailer types serving the facility. Standard assumptions do not always apply.

Door sizing is influenced by:

- Trailer height variation

- Liftgate use

- Specialized cargo handling

- Anticipated future operations

In steel buildings, door openings directly affect framing and bracing design. Industry design guidance for these structural considerations is provided by the Canadian Institute of Steel Construction. Oversized or poorly coordinated openings can increase structural cost or reduce stiffness.

Door Spacing and Utilization

Door spacing controls how many docks can be used simultaneously.

For example, misaligned door spacing can restrict trailer positioning, slow loading cycles, and increase wear on doors and levelers even when the total door count appears adequate.

Dock Levelers, Pits, and Structural Coordination

Dock levelers are not simply equipment items. They impose loads, create slab penetrations, and interact with foundations.

Key considerations include:

- Pit geometry and depth

- Load transfer into slab edges

- Frost protection and insulation detailing

- Drainage around recessed areas

In Canadian conditions, dock pits are particularly vulnerable to freeze-thaw cycles and water intrusion if not detailed correctly.

Slab Design at Dock Areas

Concentrated Loads and Impact Forces

Dock slabs experience higher stresses than typical warehouse floors due to trailer wheels, forklift impact, and repeated vibration.

Slab design must account for:

- Concentrated wheel loads

- Impact and dynamic forces

- Differential settlement risk

- Integration with foundations

Steel buildings amplify alignment issues. Slab movement at docks can affect door operation and envelope performance.

Frost and Subgrade Conditions

Dock aprons are exposed elements. Understanding frost depth and climate interaction in steel buildings is essential when designing exterior dock slabs in Canadian environments. Applying interior slab assumptions to dock areas is a common and costly mistake in Canadian projects.

Drainage and Grading at Dock Areas

Loading docks are highly sensitive to water accumulation. Many long-term operational issues originate from drainage and grading mistakes that delay steel building projects and affect dock performance.

Effective planning includes:

- Positive grading away from dock faces

- Clear meltwater paths

- Protection of dock pits and equipment

- Integration with site stormwater systems

Water issues at docks frequently trigger inspection failures and operational downtime long after construction is complete.

Safety Considerations at Loading Docks

Dock safety issues often develop gradually and are rarely caused by a single design error.

Common risks include:

- Pedestrian and forklift conflict zones

- Trailer creep during loading

- Uneven settlement at dock aprons

- Ice accumulation at dock lips and levelers

These conditions increase injury risk, equipment damage, and insurance exposure. Safety performance at docks depends as much on geometry and grading as on procedures.

Construction Sequencing and Coordination

Dock construction involves foundations, slabs, steel erection, envelope work, and equipment installation.

A common failure pattern is slab pours completed before dock pit and equipment details are finalized, forcing demolition or compromised solutions later.

Most dock-related delays originate from incomplete coordination well before steel arrives on site. This is why coordinating trades during steel building construction is essential to avoid sequencing conflicts and redesign.

Long-Term Maintenance and Lifecycle Cost Impacts

Poor dock design increases long-term cost through:

- Repeated repairs to levelers and doors

- Slab cracking and settlement

- Premature seal and shelter replacement

- Energy loss and moisture damage

Well-designed dock systems support predictable maintenance and lower lifecycle cost over decades of use.

When Dock Design Deserves Extra Attention

Dock design is especially critical when:

- Truck volumes are high

- Multiple trailer types are served

- Automation or material handling systems are used

- Operations continue year-round

- Future expansion is anticipated

In these cases, docks function as infrastructure rather than accessories.

Final Perspective

Loading docks determine how a warehouse actually operates. In steel warehouse buildings, dock design influences structural performance, workflow efficiency, safety, and lifecycle cost.

Docks are infrastructure, not accessories. Most dock problems are designed in early and paid for daily through inefficiency, repairs, and risk. When docks are planned as integral building systems, steel warehouses perform predictably under real operating conditions.

Reviewed by the Tower Steel Buildings Engineering Team

This article has been reviewed by the Tower Steel Buildings Engineering Team to ensure technical accuracy, alignment with Canadian construction practices, and relevance to real-world warehouse operations and permitting requirements.

1. How many loading docks should a steel warehouse building have?

The number of loading docks depends on throughput, trailer turnover, and operational workflow rather than building size alone. High-volume distribution centres often require more docks with tighter spacing, while manufacturing warehouses may function efficiently with fewer, strategically placed docks.

2. Do loading dock requirements differ for steel buildings compared to other construction types?

Yes. Steel buildings rely on precise structural coordination, so dock openings, pits, and canopies must be integrated into the structural design early. Late dock changes can affect framing, bracing, slab performance, and long-term alignment.

3. How does Canadian climate affect loading dock design?

In Canada, loading docks must account for frost depth, freeze-thaw cycles, snow accumulation, and ice formation. Dock aprons, pits, and drainage systems require detailing that prevents heaving, water intrusion, and winter safety hazards.

4. Who is responsible for loading dock design coordination?

Responsibility is typically shared, but problems occur when accountability is unclear. Effective projects define coordination responsibilities early between the structural engineer, dock equipment supplier, site civil designer, and general contractor.

5. Can poor dock design delay inspections or occupancy approvals?

Yes. Inspectors commonly flag drainage issues, slab settlement, unsafe access, or incomplete coordination at dock areas. These issues can delay occupancy even when the main building structure is complete.

6. How do dock designs affect long-term maintenance costs?

Dock-related maintenance often exceeds expectations when pits, slabs, or seals are poorly designed. Repeated repairs to levelers, doors, and concrete are common indicators of early design shortcomings rather than equipment failure.

7. Should dock doors and levelers be selected before structural design is complete?

Yes. Dock equipment dimensions and loads influence framing, slab reinforcement, and pit detailing. Selecting equipment late often forces structural compromises or redesign.

8. Are loading docks a common source of safety risk in warehouses?

They are one of the highest-risk zones. Pedestrian interaction, trailer movement, ice formation, and uneven surfaces contribute to incidents. Many safety issues originate from geometry and grading rather than worker behaviour.

9. Can a warehouse operate efficiently if dock design is undersized?

It may function initially, but inefficiencies accumulate quickly. Congestion, extended truck dwell times, and equipment damage often reveal that dock capacity and spacing were underestimated during design.