Design, Loads, Workflow, and Long-Term Operational Performance

Manufacturing facilities are not generic buildings. They are working environments where structure, workflow, equipment loads, and long-term durability directly influence productivity, safety, and operating cost.

In Ontario, these requirements are further shaped by climate, inspection standards, labour conditions, and regulatory oversight. Steel buildings have become the preferred structural solution for manufacturing facilities across the province because they provide predictable performance, open layouts, and the flexibility needed to support evolving production demands. These same principles apply across broader industrial operations, which are discussed further in industrial steel buildings in Ontario.

This article explains how steel buildings are designed specifically for manufacturing use in Ontario, what technical considerations matter most, and why early engineering decisions often determine whether a facility performs as intended over decades.

Who This Article Is For

This guide is intended for owners, developers, and operators planning permanent manufacturing facilities that must meet Ontario permitting requirements, pass municipal inspections, and support long-term industrial operations.

It may not apply to temporary storage structures, lightly engineered sheds, or short-term enclosures where full code compliance, equipment loading, and operational durability are not required.

Why Steel Is the Preferred Structure for Manufacturing Facilities

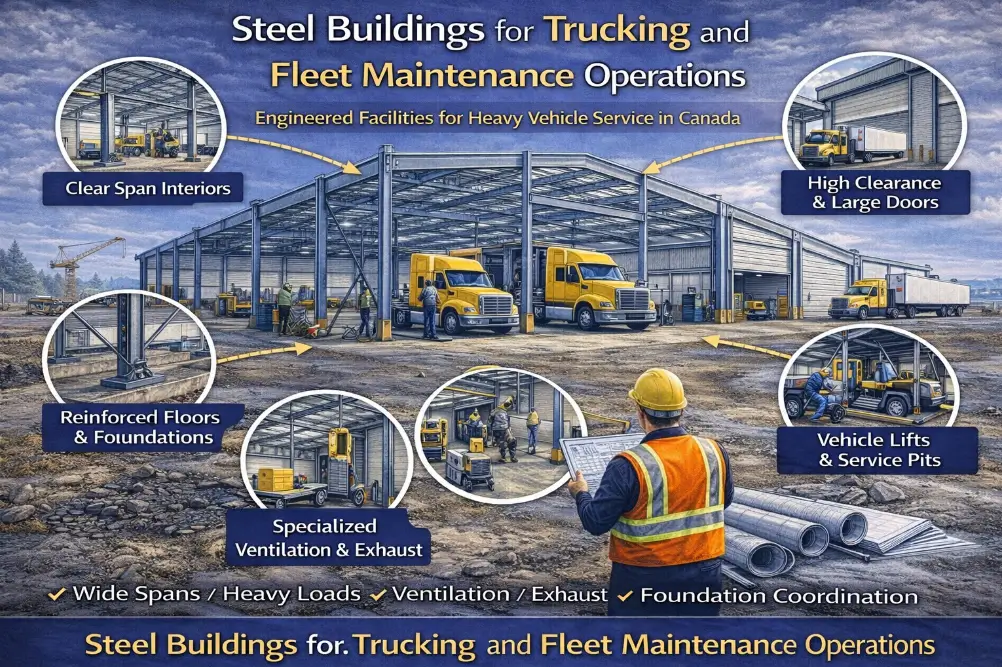

Manufacturing buildings must support more than basic roof and wall loads. They must accommodate heavy machinery, overhead systems, cranes, mezzanines, storage racks, and continuous operational use.

Steel buildings are particularly well suited to these demands.

First, steel offers predictable structural behavior. Loads are calculated, transferred, and resisted through engineered members rather than relying on material variability. This predictability is essential in environments where equipment accuracy and alignment matter.

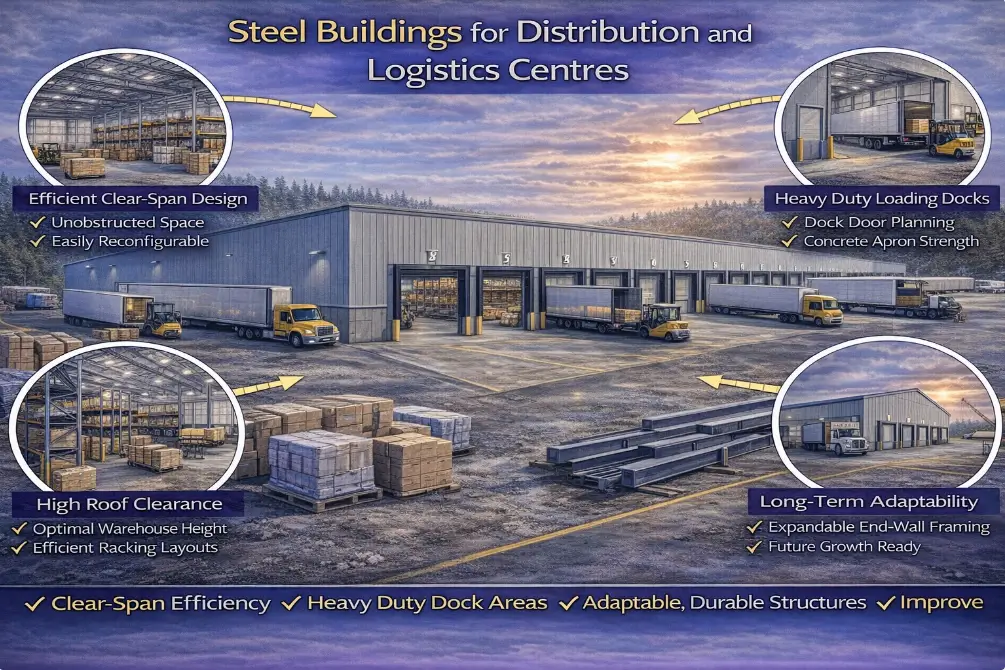

Second, steel buildings allow for clear span interiors. Open layouts improve production flow, equipment placement, and future reconfiguration while minimizing internal obstructions that disrupt manufacturing processes.

Third, steel structures provide long-term adaptability. Manufacturing operations evolve. Steel buildings can be expanded, reinforced, or reconfigured more efficiently than many traditional systems when change is required.

In Ontario, where manufacturing facilities are routinely scrutinized during permitting and inspection, steel buildings offer consistency that engineers, inspectors, and insurers recognize.

Ontario Building Code Considerations for Manufacturing Facilities

Manufacturing facilities fall under specific occupancy classifications within the Ontario Building Code. These classifications influence structural loads, fire separation requirements, egress design, and safety provisions.

Key considerations include:

- Structural load criteria based on industrial use

- Snow and wind loads specific to the project location

- Fire resistance ratings and separation requirements

- Clearances for equipment, exits, and emergency access

- Foundation design based on soil conditions and frost depth

While the Ontario Building Code establishes minimum acceptable performance, manufacturing facilities often require designs that exceed baseline assumptions due to equipment loads, vibration sensitivity, and operational intensity.

Steel buildings allow these higher demands to be addressed efficiently when design intent is clearly defined early.

Structural Loads Unique to Manufacturing Buildings

Manufacturing environments introduce loads that are not present in storage or light commercial buildings. These load conditions are examined further in structural steel buildings in Ontario, where framing, connections, and load paths are engineered for demanding industrial use.

Equipment Loads

Production machinery often creates concentrated loads on slabs and structural framing. These loads must be identified early so slab thickness, reinforcement, and foundation design can be coordinated correctly.

When equipment loads are ignored or underestimated, costly slab retrofits or structural reinforcements often follow installation.

Overhead Cranes and Hoisting Systems

Many manufacturing facilities require overhead cranes, jib cranes, or monorail systems. These systems introduce vertical loads, lateral forces, and dynamic effects that directly influence primary framing, column design, and bracing.

Crane systems are not accessories. They are structural elements that must be integrated into the building design from the outset. This integration is critical in facilities where material handling drives layout, as outlined in steel warehouse racking and forklift clearance requirements.

Mezzanines and Elevated Platforms

Mezzanines are commonly used for storage, offices, or process staging. These structures add vertical loads and vibration considerations that affect framing design and foundation performance.

Steel buildings allow mezzanines to be integrated efficiently when planned early, rather than added later as standalone structures.

Workflow, Layout, and Operational Efficiency

A manufacturing building succeeds or fails based on how well it supports daily operations.

Clear Span Planning

Clear span steel buildings support linear production lines, flexible equipment layouts, and efficient material movement. Interior columns often restrict workflow and complicate future changes. This is one reason clear-span layouts are also prioritized in steel buildings for auto repair shops, where uninterrupted floor space directly affects productivity.

Door Placement and Logistics

Manufacturing facilities require carefully planned door locations for shipping, receiving, and internal transport. Overhead doors, dock doors, and personnel access points must align with production flow and safety requirements.

Vertical Clearance

Ceiling height affects equipment installation, ventilation systems, lighting, and crane operation. Underestimating clearance needs often creates operational constraints that are difficult to correct later.

Steel structures allow designers to address both current and future clearance needs without unnecessary material use.

Foundation Design for Manufacturing Steel Buildings

Foundations for manufacturing facilities require careful coordination with structural design and site conditions.

Soil Conditions and Frost Protection

Ontario soils range from dense granular materials to highly plastic clays. Foundation design must account for bearing capacity, frost depth, drainage, and long-term settlement behavior. These factors are examined in greater detail in steel building foundation design in Ontario, particularly where soil variability affects long-term performance.

Steel buildings transfer loads precisely to foundations. This precision exposes foundation issues quickly, making proper geotechnical evaluation essential.

Equipment Pads and Isolated Foundations

Heavy machinery often requires isolated pads or thickened slab sections. These must be coordinated with the main foundation system to avoid differential movement or cracking.

When foundation design is separated from building design, conflicts frequently arise during construction.

Environmental Control and Energy Performance

Manufacturing facilities often require controlled interior environments for equipment performance, product quality, or worker comfort.

Insulation and Thermal Performance

Steel buildings can be insulated to support a wide range of operating conditions, from frost protection to fully conditioned production environments. Insulation strategy should reflect operating hours, internal heat gains, and ventilation needs.

Ventilation and Air Quality

Manufacturing processes generate heat, fumes, or particulates that require engineered ventilation. Roof and wall systems must accommodate penetrations and airflow paths without compromising structural or weather performance.

Moisture and Condensation Control

Condensation can damage equipment and materials. Proper vapor barrier placement and thermal detailing are critical in manufacturing environments.

Durability, Maintenance, and Lifecycle Performance

Manufacturing buildings are long-term assets. Design decisions directly influence maintenance requirements and operational reliability.

Steel structures offer:

- Resistance to rot, mold, and pest damage

- Predictable long-term structural performance

- Compatibility with durable exterior cladding systems

- Reduced maintenance compared to many alternative systems

When properly engineered, constructed, and maintained, steel manufacturing buildings commonly support 30 to 40 years of structural performance, depending on coatings, exposure conditions, and foundation quality.

This durability also influences insurance acceptance and long-term asset value. Similar lifecycle considerations apply to warehouse steel buildings in Ontario, where long-term operational continuity is a priority.

Engineering Documentation and Quality Expectations

Manufacturing facilities benefit from comprehensive engineering documentation that addresses both structural performance and constructability.

Complete documentation typically includes:

- Fully engineered drawings stamped by licensed professional engineers

- Coordinated foundation and slab designs

- Defined load paths and connection detailing

- Deflection and vibration criteria appropriate to manufacturing use

- Erection considerations aligned with equipment installation

In Canada, engineered steel building systems are typically manufactured and certified in accordance with CSA A660 certification for steel building systems.

Structural drawings and calculations are reviewed and sealed by licensed professional engineers in Ontario, ensuring accountability and regulatory compliance.

Incomplete or phased engineering often leads to redesigns, inspection delays, and construction conflicts. These risks are explored further in steel building engineering practices in Ontario, particularly where permitting and inspections intersect.

Why Experience Matters in Manufacturing Facility Design

Designing steel buildings for manufacturing is not theoretical. It requires understanding how facilities operate in practice.

Experience informs decisions about:

- Where loads truly occur

- How equipment installation affects structure and foundations

- How inspectors interpret code requirements

- How construction sequencing affects production schedules

Facilities designed with operational realities in mind experience fewer disruptions and smoother approvals.

Steel Buildings as Manufacturing Infrastructure

A manufacturing building is more than an enclosure. It is infrastructure that enables production, safety, and growth.

Steel buildings provide the reliability, adaptability, and efficiency required for Ontario’s manufacturing sector. When designed with manufacturing realities in mind, a steel building becomes a long-term operational asset rather than a constraint.

Reviewed by the Tower Steel Buildings Engineering Team

This article has been reviewed by the Tower Steel Buildings Engineering Team to confirm technical accuracy, alignment with Ontario permitting practices, and consistency with real-world manufacturing facility design and construction experience.

The guidance reflects direct involvement in engineered steel manufacturing projects across Ontario and Canada, incorporating lessons learned from permitting, inspection, fabrication, and erection.

1. Are steel buildings suitable for heavy manufacturing equipment?

Yes. Steel buildings are commonly engineered to support heavy equipment loads, overhead cranes, and dynamic forces when those requirements are identified early in the design process.

2. Do manufacturing steel buildings require specialized foundations?

Often, yes. Equipment loads, soil conditions, and frost depth typically require customized foundation and slab designs coordinated with the steel structure.

3. Can steel manufacturing buildings be expanded in the future?

Steel buildings can be designed with future expansion in mind. Structural framing, foundations, and site layout can often accommodate phased additions when planned early.

4. How long do steel manufacturing buildings typically last?

With proper engineering, coatings, foundations, and maintenance, steel manufacturing buildings commonly achieve 30 to 40 years or more of structural service life.

5. Do manufacturing facilities face stricter inspections than warehouses?

Yes. Manufacturing occupancies often receive closer scrutiny due to equipment loads, fire safety requirements, and operational risks. Comprehensive engineering documentation helps streamline approvals.