Deciding to move forward with a steel building is rarely a sudden decision. For most owners, developers, and operators, it is the result of a series of practical signals coming together over time. These signals often relate to planning readiness, operational clarity, financial alignment, and regulatory awareness rather than enthusiasm or urgency.

This article outlines the most reliable signs that indicate when a project is genuinely ready to proceed. It is written for buyers planning permanent steel buildings in Canada, where permitting, engineering, climate, and long-term performance matter. It may not apply to temporary shelters or lightly engineered structures intended for short-term use.

Understanding readiness before committing to fabrication or contracts reduces delays, change orders, and cost escalation. In many cases, the difference between a smooth project and a difficult one is not budget. It is timing and preparation.

You Have a Clear and Stable Purpose for the Building

One of the strongest indicators of readiness is clarity of use.

Buyers who struggle during steel building projects often change direction midstream. Storage becomes manufacturing. A workshop becomes fleet maintenance. A warehouse suddenly needs overhead cranes or racking loads that were not planned.

If you can clearly answer the following questions, you are likely ready to proceed:

- What will the building be used for on day one

- How will it be used daily

- What equipment or vehicles must fit comfortably inside

- Whether the use is seasonal or year-round

- Whether future expansion is anticipated

Steel buildings are highly adaptable, but design decisions must be aligned with use early. When purpose is stable, engineering assumptions remain valid and costs stay predictable.

Your Site Is Identified and Realistically Understood

Projects are often delayed not because a site is unavailable, but because it is not fully understood.

Being ready means more than owning or leasing land. It means having a practical understanding of site realities, including:

- Access for deliveries and cranes

- General grading conditions

- Drainage behaviour during rain and spring melt

- Proximity to neighbouring structures

- Available space for staging during construction

You do not need a finished site to move forward, but you do need awareness. This is especially true when evaluating steel building site preparation considerations before final design begins.

Steel building design depends heavily on foundation coordination and erection planning, particularly when considering steel building foundation requirements in Canada. When site unknowns are left unresolved, they surface later as delays or redesigns.

You Are Prepared to Engage Engineering Early

A clear sign of readiness is willingness to engage proper engineering early in the process.

Many buyers try to delay engineering to reduce upfront cost. In practice, this often increases total project cost. Engineering defines load paths, foundation reactions, connection requirements, and erection sequencing, all of which are explained in detail in our guide to steel building engineering in Canada. Without it, drawings remain assumptions rather than commitments.

Industry standards for structural steel design are supported by the Canadian Institute of Steel Construction.

If you are ready to:

- Review engineered drawings

- Coordinate foundation design with steel reactions

- Allow time for permit review and revisions

- Ask questions about loads, deflection, and performance

then your project is approaching the right stage to move forward.

You Understand That Permits Influence Timelines

In Canada, steel building schedules are shaped as much by permitting and inspections as by fabrication speed. Building permit review processes are governed under the National Building Code of Canada.

Buyers who are ready recognize that:

- Permit timelines vary by municipality, and understanding steel building zoning and permit requirements in Canada early helps prevent delays.

- Engineering review may require revisions

- Foundations are often inspected before steel delivery

- Seasonal conditions affect inspection availability

If you have allowed time for approvals and are not relying on unrealistic timelines, that is a strong indicator of readiness. Projects that attempt to rush permitting often experience longer delays than those planned conservatively.

Your Budget Is Aligned With Scope, Not Just Size

Readiness is not defined by having a number in mind. It is defined by understanding what that number must include.

A realistic steel building budget considers:

- Structural engineering

- Fabrication quality

- Foundation requirements

- Delivery logistics

- Erection planning

- Climate and exposure conditions

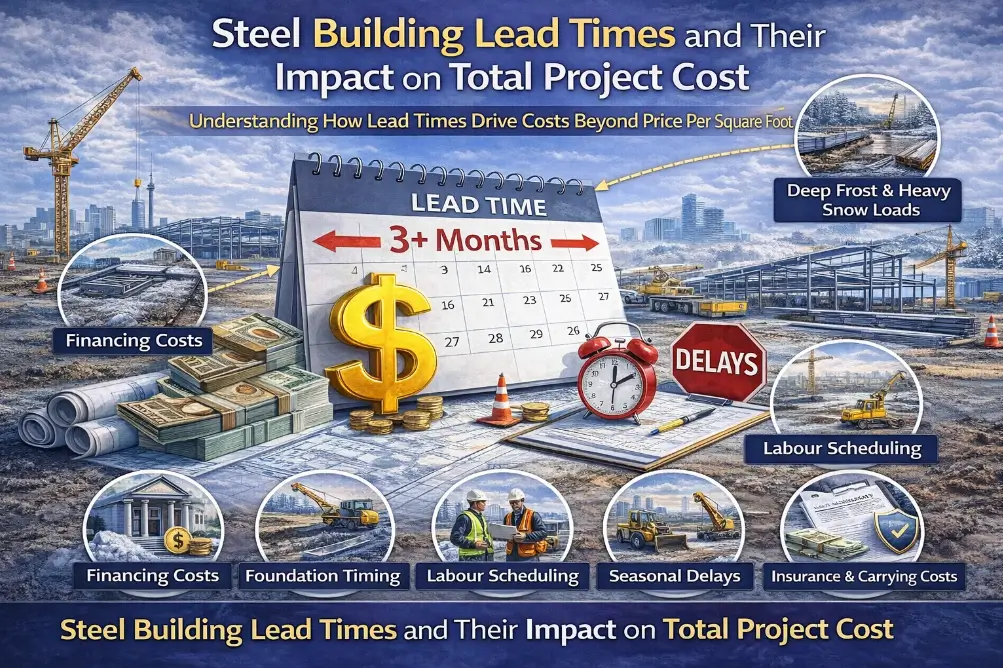

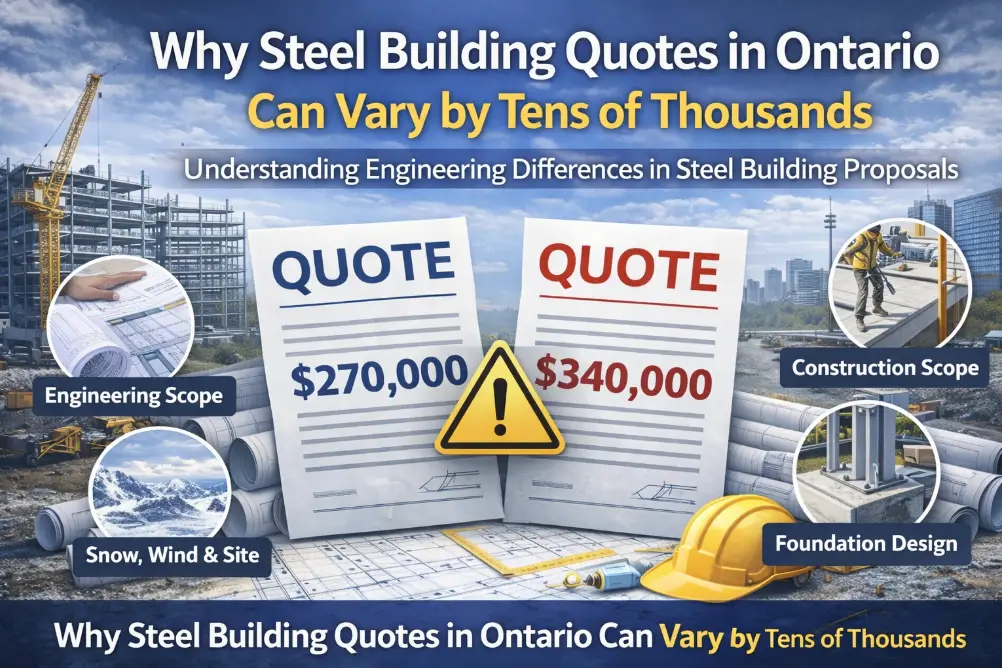

Understanding how pricing varies by engineering scope is critical, which is why reviewing why steel building quotes vary in Canada helps set realistic expectations.

Buyers who are ready understand that two buildings of the same size can differ significantly in cost based on use, location, and performance requirements. When expectations align with scope, decision-making becomes straightforward.

You Have Considered Long-Term Ownership, Not Just Initial Cost

Steel buildings are long-term assets. Long-term performance planning should account for regional climate data published by Environment and Climate Change Canada. Owners who are ready think beyond the first invoice.

Signs of long-term thinking include:

- Asking about corrosion protection

- Understanding roof and wall system performance

- Considering insulation and condensation control

- Thinking about maintenance access

- Evaluating operational downtime risk

Projects driven only by lowest upfront price often incur higher costs later through maintenance, repairs, or operational inefficiencies. This lifecycle perspective is explored further in our analysis of long-term steel building cost savings. Readiness means valuing lifecycle performance as much as initial cost.

You Know What Level of Customization You Actually Need

Steel buildings offer extensive customization, but not every project requires every option.

Being ready means understanding:

- Which features are essential

- Which features are optional

- Which features can be added later

- Which features must be designed in from the start

Examples include door sizes, crane capacity, mezzanines, insulation systems, and clear spans. These decisions often determine structural assumptions, especially in custom steel building applications across Canada. When customization decisions are intentional rather than reactive, projects move faster and cost less.

You Are Comfortable Asking Technical Questions

Buyers who are ready are not afraid to ask detailed questions.

These may include:

- How loads are calculated

- How foundations are coordinated

- How erection sequencing works

- What assumptions are being made

- What happens if conditions change

This is not a sign of distrust. It is a sign of engagement. Steel building projects benefit when owners understand how decisions affect performance and cost.

You Have Identified Who Will Be Involved in the Project

Readiness includes clarity around roles and responsibilities.

This may involve:

- Owner representatives

- Engineers

- Foundation contractors

- Erection crews

- Municipal inspectors

Projects often slow down when responsibilities are assumed rather than defined. Knowing who will make decisions, who will coordinate trades, and who will respond to issues keeps momentum intact.

You Accept That Preparation Determines Speed

One of the most misunderstood aspects of steel building projects is speed.

Steel buildings can be erected quickly, but only when prerequisites are complete. Most delays originate before steel arrives on site.

If you recognize that:

- Foundations control schedules

- Access controls erection

- Permits control delivery

- Coordination controls progress

then you are approaching the project with the right mindset. Readiness is not about rushing. It is about sequencing.

You Are Looking for Predictability, Not Just a Quote

Finally, a strong indicator of readiness is the desire for predictability.

Buyers who are ready want to know:

- What assumptions are included

- What is excluded

- Where risks exist

- How changes will be handled

This approach leads to fewer surprises and better outcomes. Steel building projects reward clarity and discipline far more than optimism.

Bringing the Signals Together

No single sign determines readiness. It is the combination that matters.

Projects tend to move smoothly when owners:

- Have a defined purpose

- Understand their site

- Engage engineering early

- Respect permitting realities

- Align budget with scope

- Think long-term

- Ask informed questions

- Plan coordination carefully

When these conditions are present, moving forward with a steel building is not a gamble. It is a structured decision.

Organizations such as Tower Steel Buildings see the difference clearly. Projects that begin with readiness move efficiently through design, permitting, fabrication, and erection, especially when working with experienced providers of turnkey steel building projects in Canada.

Projects that begin prematurely often spend more time correcting assumptions than building.

The most successful steel buildings are not rushed. They are prepared.

Reviewed by the Tower Steel Buildings Engineering Team

This content has been reviewed for technical accuracy, real-world applicability, and alignment with Canadian steel building design, permitting, and construction practices.

1. How do I know if I am truly ready to start a steel building project?

You are ready when the building purpose is clearly defined, the site is identified, and you understand that engineering, permitting, and foundation planning will influence timelines and cost. Readiness is less about urgency and more about clarity and preparation.

2. Do I need to own land before starting steel building design?

Not always, but having a confirmed site significantly improves design accuracy. Engineering decisions such as snow load, wind exposure, frost depth, and access planning depend on location. Conceptual planning can start earlier, but final design requires site-specific information.

3. What is the most common reason steel building projects get delayed after signing?

Delays most often occur due to unresolved foundation design, incomplete site preparation, or permit review issues. These delays usually originate before steel fabrication begins, not during erection itself.

4. Can I get an accurate steel building quote before engineering is complete?

Preliminary ranges can be discussed, but accurate pricing depends on defined engineering scope. Load requirements, foundation reactions, and connection design all influence material quantities and fabrication details. Quotes issued without this clarity often change later.

5. Who is responsible for foundation design on a steel building project?

Foundation design is typically handled by a structural engineer, coordinated with the steel building reactions. While steel suppliers provide loading information, foundations must be designed for site conditions, soil capacity, and local code requirements.

6. Is it risky to change building use after design has started?

Yes. Changing use after design can trigger engineering revisions, permit amendments, and cost increases. Steel buildings are adaptable, but assumptions about loads, openings, and clearances must align with final use to avoid redesign.

7. How early should I involve municipal permitting authorities?

As early as practical. Understanding zoning, setbacks, and permit timelines early helps avoid redesign and scheduling conflicts. Early awareness is often more valuable than early submission.

8. Does long-term ownership really affect steel building design decisions?

Absolutely. Decisions around corrosion protection, insulation, drainage coordination, and structural redundancy influence maintenance costs and service life. Buildings designed with long-term operation in mind typically deliver better value over decades.

9. What questions should I be asking before approving steel fabrication?

Key questions include what assumptions the design is based on, how changes are handled, how erection sequencing is considered, and what coordination is required with foundations and other trades. Clear answers indicate a well-prepared project.

10. Is moving forward with a steel building mostly about budget readiness?

Budget is important, but it is not the primary signal of readiness. Projects succeed when scope, site conditions, engineering, and approvals are aligned. Budget alone cannot compensate for unresolved technical or regulatory issues.