Finalizing a steel building design is not a paperwork milestone. It is the point where assumptions become commitments and where design decisions begin to affect cost, schedule, permitting, and long-term performance.

In Canada, steel building projects often move forward with drawings that are technically complete but not fully coordinated. That gap is where redesigns, change orders, inspection delays, and operational issues originate. An engineering review checklist helps prevent those problems by forcing clarity before fabrication begins.

This article outlines a practical engineering review checklist that should be completed before finalizing a steel building design. It is written for owners and project teams planning permanent steel buildings where code compliance, constructability, and lifecycle performance matter.

Who This Article Is For

This article is intended for owners, developers, and project managers planning permanent steel buildings in Canada that require permits, inspections, and long-term operational reliability. It may not apply to temporary structures or lightly engineered enclosures where full coordination is not required.

Why an Engineering Review Checklist Matters

Steel buildings are engineered systems. Each component depends on the accuracy of the others. When one assumption is wrong or incomplete, the correction rarely stays isolated.

Engineering reviews are not about questioning competence. They are about confirming alignment. Early coordination is also a primary method of managing construction risk in steel building projects.

Most project issues are not caused by design errors, but by design gaps. Gaps between disciplines. Gaps between drawings. Gaps between intent and execution.

A structured checklist ensures that the design reflects how the building will actually be built, permitted, and used.

Site Conditions and Geotechnical Assumptions

Confirm Site Data Is Final

Engineering should not be finalized until site information is reliable. This includes:

- Verified property boundaries and setbacks

- Confirmed elevations and grading strategy

- Final building orientation

Designs based on preliminary site data often require revision once surveys or grading plans change.

Review Geotechnical Inputs

Foundation design depends on soil conditions, frost depth, and groundwater assumptions. Site investigation procedures follow professional geotechnical engineering practice guidelines.

Proper evaluation begins with understanding soil conditions affecting steel building foundations in Canada.

Confirm that:

- Soil bearing values are site-specific

- Frost depth reflects local requirements

- Seasonal and perched water conditions are considered

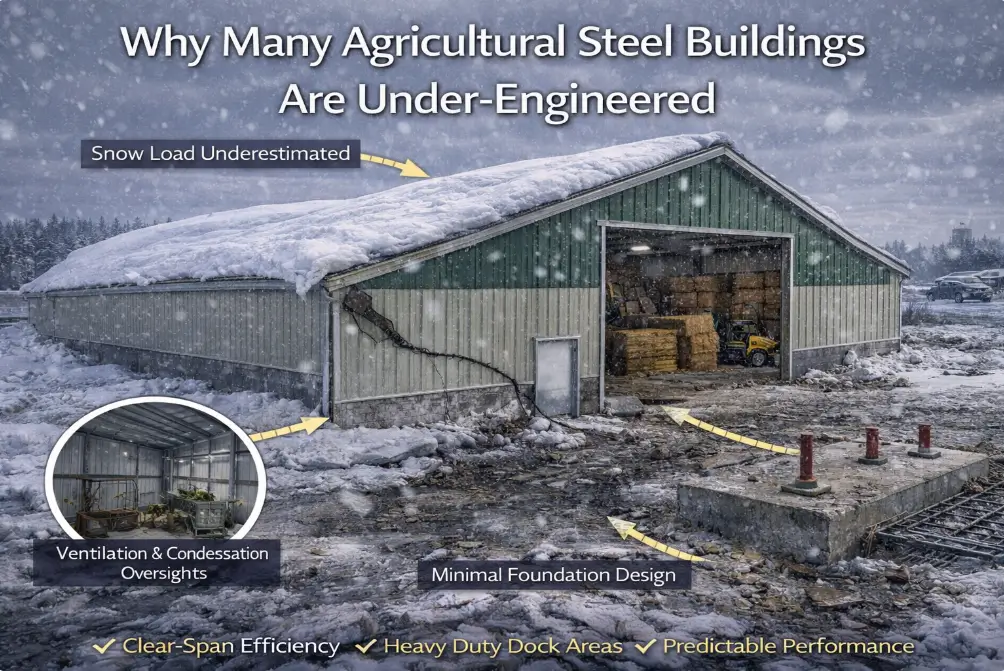

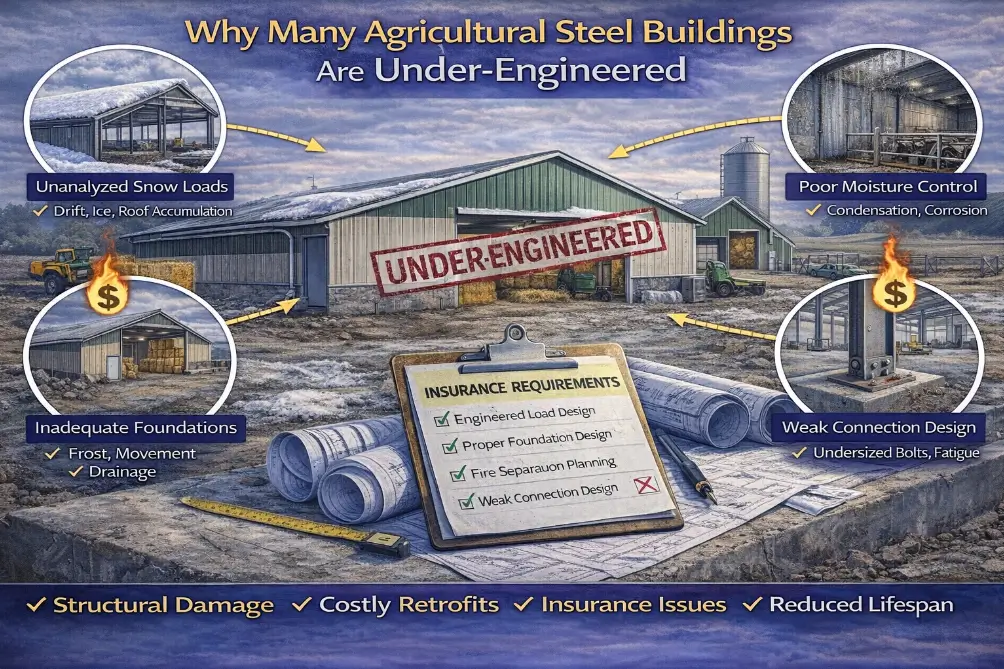

Steel buildings are sensitive to foundation movement. This is why designers must account for frost depth effects on steel building foundations during engineering review. Incorrect geotechnical assumptions often result in costly foundation revisions after permits are submitted.

Code Compliance and Load Criteria

Confirm Applicable Codes

Ensure the design references the correct governing codes:

- National Building Code of Canada

- Applicable provincial or municipal amendments

- CSA standards where required

Design provisions for steel structures are governed by CSA structural steel design standards.

Technical requirements are defined in the National Building Code of Canada official publication.

Code references should reflect the project location, not generic assumptions reused from previous projects.

Review Load Criteria

Verify that all relevant loads are clearly defined and documented:

- Snow loads based on local climate data

- Wind loads reflecting exposure category

- Seismic parameters where applicable

- Live loads consistent with actual building use

In Canada, load assumptions vary significantly by region. Designs that rely on default values often fail during permit review.

Structural System and Load Path Review

Primary Framing System

Confirm that the primary framing system aligns with:

- Clear span and interior clearance requirements

- Crane, mezzanine, or equipment loads if applicable

- Planned or potential future expansion

Frame selection directly affects foundation reactions, erection sequencing, and long-term flexibility.

Secondary Framing and Bracing

Review secondary members and bracing systems to ensure:

- Lateral loads are clearly transferred

- Bracing locations do not interfere with doors or equipment

- Redundancy is appropriate for the building’s operational risk profile

Incomplete bracing coordination is a common source of late-stage design changes.

Load Path Continuity

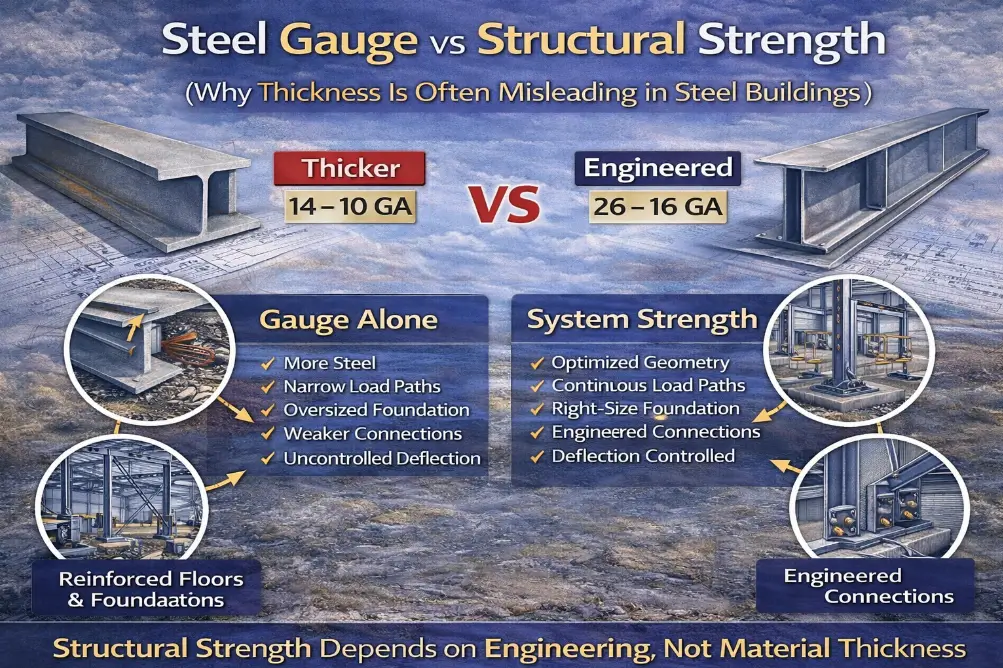

Every load must have a clear path from roof to foundation. System reliability also depends on structural redundancy principles in steel building design.

Confirm that:

- Connections are engineered, not assumed

- Deflection limits are appropriate for finishes and equipment

- No load paths rely on non-structural elements

Foundation Coordination Review

Confirm Steel Reactions Are Final

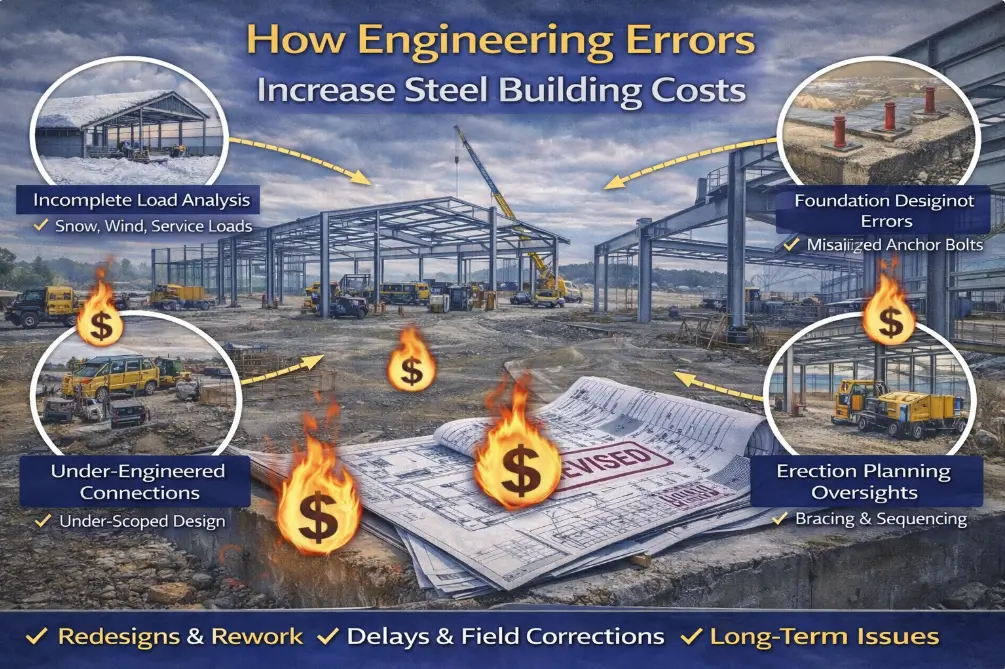

Foundation design should be based on final steel reactions, not preliminary estimates. Changes after foundation drawings are issued frequently trigger redesign, re-approval, and inspection delays.

Review Foundation Types and Detailing

Confirm that foundation systems align with site conditions and use:

- Shallow versus deep foundation selection

- Slab-on-grade thickness and reinforcement

- Anchor bolt layouts and placement tolerances

Clear-span and long-span steel buildings tolerate far less foundation error than column-supported structures.

Openings, Penetrations, and Attachments

Door and Opening Locations

Confirm all door sizes, locations, and types before design finalization. Late changes often affect:

- Primary framing

- Bracing layouts

- Lateral load resistance

Roof and Wall Penetrations

Review penetrations for:

- Mechanical and ventilation systems

- Process equipment

- Future service allowances

Uncoordinated penetrations are a frequent cause of field modifications and inspection concerns.

Building Use and Operational Loads

Confirm Actual Building Function

Ensure the design reflects how the building will be used in practice, not just how it is described. Review:

- Storage heights and racking systems

- Equipment and vehicle loads

- Traffic patterns and maintenance access

- Crane systems if applicable

A building can meet minimum code requirements and still be poorly engineered for its actual use.

Review Floor Load Assumptions

Confirm slab and foundation loads reflect:

- Concentrated equipment loads

- Forklift and truck traffic

- Point loads from storage systems

Operational loads are commonly underestimated during early design stages.

Erection and Constructability Review

Erection Sequencing

Confirm the design considers how the structure will be erected:

- Temporary stability during erection

- Crane access and lift paths

- Member sizes, weights, and handling constraints

Designs that ignore erection realities often require costly field adjustments.

Temporary Bracing Requirements

Review assumptions related to temporary bracing and stability during construction. Inadequate planning can introduce safety risks and schedule delays.

Coordination and Responsibility Boundaries

Steel building coordination often fails not because people are unwilling, but because responsibility is assumed rather than assigned.

At minimum, confirm:

- Who provides final equipment loads

- Who coordinates penetrations and openings

- Who confirms foundation assumptions

- Who reviews erection sequencing impacts

These items frequently fall between scopes unless explicitly acknowledged early.

Risk and Change Management Review

Identify High-Risk Assumptions

Flag assumptions that may change later, such as:

- Future crane installation not fully documented

- Tenant modifications assumed but not engineered

- Planned expansion noted conceptually but not detailed

For example, a building designed without confirmed crane loads may meet initial code requirements but require major structural reinforcement later, often after fabrication has begun.

Review Tolerances and Allowances

Confirm tolerances for fabrication, erection, and foundation work are realistic and documented.

Fabrication Release Stop-Point

Design should not be released for fabrication if any of the following remain unresolved:

- Final steel reactions are not issued to foundation design

- Equipment, crane, or racking loads are unknown or provisional

- Major penetrations or openings are unconfirmed

- Erection access or sequencing conflicts remain

- Conflicting information exists between drawings

Once steel is fabricated, flexibility decreases rapidly and costs escalate.

Cost and Schedule Implications

Understand Cost Drivers

Engineering decisions directly influence:

- Steel tonnage and connection complexity

- Foundation size and reinforcement

- Erection duration and crane time

Reducing engineering scope early often increases total project cost later.

Avoid False Economy

Shortening the engineering phase rarely shortens the project. It typically shifts risk downstream where corrections are more expensive.

Final Engineering Sign-Off Checklist

Site and Code

- Site data verified and final

- Codes and load criteria location-specific

- Geotechnical assumptions confirmed

Structure and Foundations

- Primary and secondary framing coordinated

- Bracing and load paths complete

- Foundations designed to final steel reactions

Operations and Erection

- Actual building use reflected in design

- Erection sequencing reviewed

- Temporary stability considered

Documentation and Risk

- Drawings complete and consistent

- High-risk assumptions documented

- Responsibility boundaries acknowledged

Closing Perspective

Engineering reviews do not slow projects down. They prevent projects from slowing themselves down later.

In steel construction, accurate engineering costs less than correction. A disciplined review checklist turns design completion into a confident release, not a hopeful one. Fully coordinated design reviews are standard practice in turnkey steel building project delivery systems.

Reviewed by the Tower Steel Buildings Engineering Team

This article has been reviewed by the Tower Steel Buildings Engineering Team, drawing on decades of combined experience in structural steel design, foundation coordination, and steel building delivery across Canada.

The review ensures the checklist reflects real permitting practices, fabrication constraints, and construction-stage risks encountered on Canadian steel building projects.

1. At what point should an engineering review checklist be completed?

An engineering review checklist should be completed before drawings are released for fabrication, not after permit submission or contract signing. Once steel is fabricated, correcting design gaps becomes significantly more expensive and disruptive.

2. Who is responsible for completing the engineering review checklist?

Responsibility is shared. Structural engineers typically confirm code compliance and load paths, while owners, project managers, and steel suppliers must verify site data, equipment loads, and coordination inputs. Problems arise when responsibility is assumed rather than confirmed.

3. Can a steel building be permit-approved but still poorly coordinated?

Yes. A design can meet minimum code requirements and still be poorly coordinated for erection, operations, or future use. Permit approval does not guarantee constructability, cost certainty, or long-term performance.

4. Why do foundation issues often appear after steel design is finalized?

Foundation issues typically appear when steel reactions change, soil assumptions are incomplete, or site grading evolves after design. This is why foundation coordination must be reviewed using final steel reactions, not preliminary values.

5. Should erection sequencing be reviewed during engineering?

Yes. Erection sequencing affects member sizing, temporary bracing needs, crane access, and safety planning. Designs that ignore erection realities often require field modifications that increase cost and delay schedules.

6. How do unconfirmed equipment loads affect steel building costs?

Unconfirmed loads often force conservative assumptions or late-stage redesigns. Both outcomes increase cost. Accurate equipment and operational load data early in design reduces steel tonnage, foundation size, and change orders.

7. Is a checklist still necessary for smaller steel buildings?

Yes. Smaller projects often have tighter budgets and less tolerance for rework. Even modest steel buildings can experience major delays if coordination gaps are discovered after fabrication begins.

8. Can an engineering checklist reduce inspection delays?

Yes. Clear documentation, coordinated drawings, and resolved assumptions reduce inspector questions and resubmissions. Many inspection delays stem from missing or conflicting information rather than structural deficiencies.

9. How does this checklist support long-term building performance?

By aligning design with actual use, site conditions, and erection realities, the checklist helps prevent settlement issues, connection problems, and operational limitations that emerge years after construction.

10. What is the most common mistake teams make before releasing steel for fabrication?

Releasing drawings with unresolved assumptions. This includes provisional loads, incomplete penetration coordination, or foundation designs based on outdated steel reactions.

et test

Your description goes here. Edit or remove this text inline or in the description settings