Building a steel structure is an exciting investment – but the success of your project begins long before the first beam is set in place.

Choosing the right site can make or break your build. The right property will save you money, simplify permitting, and ensure your building performs well for decades.

In Ontario, site selection must consider soil quality, zoning, drainage, accessibility, and environmental factors. This guide walks you through each step of steel building site selection in Ontario, with real insights from Tower Steel Buildings, a leading local manufacturer and design-build specialist.

Understand Zoning and Local Bylaws

Before you purchase land or break ground, confirm that the property’s zoning allows the type of building you plan to construct.

Why zoning matters:

- It defines what types of buildings are permitted (commercial, agricultural, industrial, residential).

- It determines setbacks – how far your structure must be from property lines, roads, and water bodies.

- It may limit building height, use, or appearance in certain districts.

Ontario example:

In Durham Region, agricultural zones often permit steel workshops or barns without a full change of use, while urban commercial zones may require site plan approval for steel-framed retail or storage buildings.

Checklist:

- Contact your local planning department or check the municipal website.

- Review zoning maps and setback requirements.

- Confirm maximum building coverage (percentage of lot area).

- Identify if the site lies in a conservation or floodplain zone.

Tower Steel Tip:

Tower Steel’s team helps clients verify zoning compliance early, preventing costly delays during permit review.

Assess Accessibility and Transportation Routes

Good site access is crucial for both construction and long-term use.

Your location should accommodate delivery trucks, cranes, and service vehicles safely.

Key factors:

- Road access: Check width, grade, and weight capacity of nearby roads.

- Turning radius: Ensure trucks and trailers can turn and back into the site.

- Proximity to highways: Convenient access can reduce delivery costs and logistics challenges.

- Year-round maintenance: Municipal snow clearing and gravel upkeep affect site usability in winter.

Ontario example:

A client near Orillia selected a property along a maintained county road rather than a private lane. That choice saved over $5,000 annually in snow removal and truck access costs.

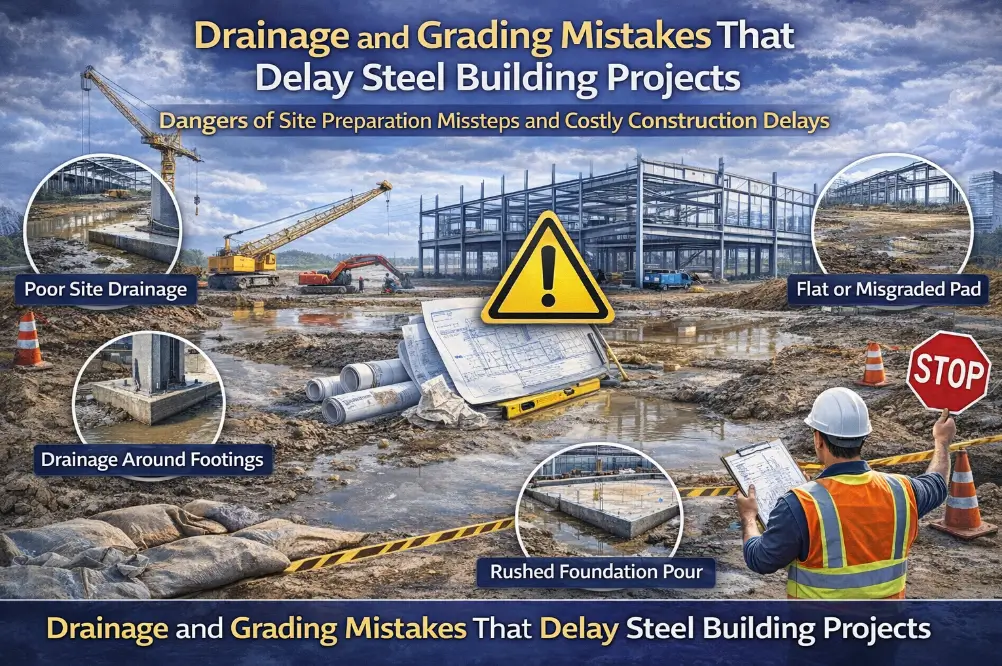

Evaluate Drainage and Water Flow

Ontario’s freeze-thaw cycle can create drainage issues if not planned properly.

Poor water management leads to foundation cracking, corrosion, and soil shifting over time.

Checklist for evaluating drainage:

- Look for natural slopes that promote runoff without pooling.

- Avoid low-lying areas or flood-prone zones.

- Check for existing ditches, culverts, or swales to divert surface water.

- Ensure grading allows water to flow away from the future foundation.

If your property lacks proper drainage, you may need engineered solutions like French drains, swales, or gravel beds.

Tower Steel Buildings often collaborates with local civil engineers to integrate drainage plans into the building’s foundation design.

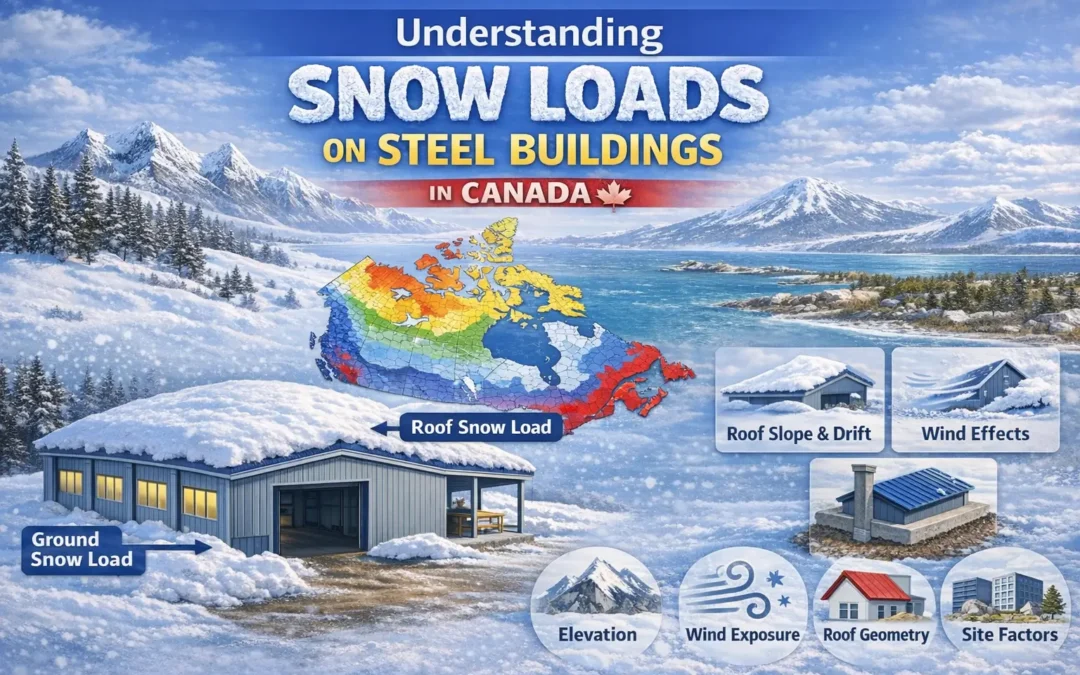

Test Soil and Ground Conditions

The quality of your soil directly impacts the foundation design and cost.

Ontario has diverse soil profiles – from sandy loam in Essex County to heavy clay in the GTA and limestone in eastern regions.

Steps for proper evaluation:

- Hire a geotechnical engineer to perform soil testing.

- Determine bearing capacity – how much weight the soil can safely support.

- Identify frost depth (typically 4–5 feet in most Ontario regions).

- Check for organic material or fill that may need to be removed.

Ontario example:

A warehouse project near London required soil stabilization before pouring concrete due to high clay content. The added preparation ensured the foundation stayed level through freeze-thaw cycles.

Tower Steel Tip:

Tower Steel provides engineer-stamped foundation drawings tailored to soil reports, preventing costly over-engineering or structural issues later.

Consider Orientation and Sunlight

Orientation affects energy efficiency, interior lighting, and snow management.

By positioning your building correctly, you can take advantage of natural light and minimize heating costs during Ontario’s long winters.

Smart orientation practices:

- Face large doors or loading bays south or east to reduce snow buildup.

- Position office or windowed areas to maximize sunlight.

- Align roof slope to direct runoff away from walkways or driveways.

- Account for prevailing winds when placing vents or openings.

Ontario example:

A shop in North Bay oriented its garage doors south-facing, preventing snowdrifts from blocking access and improving winter energy efficiency.

Check Utility Availability

Your site needs access to essential utilities for the building’s intended use.

Utility checklist:

- Hydro availability and transformer proximity.

- Water service or well access.

- Sewage or septic system capacity.

- Natural gas or propane access.

- High-speed internet and communications lines (critical for commercial sites).

If utilities are unavailable, plan for alternative systems – such as well water, septic tanks, or solar panels.

Tower Steel Buildings can integrate mechanical and electrical requirements into the early design stage to prevent layout conflicts later.

Review Environmental and Conservation Considerations

Many parts of Ontario are governed by conservation authorities that regulate construction near wetlands, rivers, and environmentally sensitive areas.

Before building, confirm:

- Whether your property falls within a Conservation Authority jurisdiction (e.g., TRCA, LSRCA).

- If the site is affected by natural hazard mapping or protected vegetation zones.

- Any required permits for grading, fill, or drainage alterations.

Ontario example:

A client in Oshawa planned to build near a small creek. Early consultation with the Central Lake Ontario Conservation Authority allowed adjustments to the layout without delaying permits.

Plan for Construction Equipment and Staging Areas

A good site layout includes room for cranes, lifts, and material storage during construction.

Underestimating space for staging can slow progress or increase safety risks.

Checklist:

- Designate laydown zones for steel bundles and panels.

- Provide flat, compacted access routes for forklifts and trucks.

- Ensure clear overhead access for cranes and telehandlers.

- Maintain separation between construction and operational areas if building on an active site.

Tower Steel’s project managers plan equipment access and offloading with each delivery – ensuring safe, efficient assembly once materials arrive.

Review Permitting and Approvals Early

Permitting is often one of the longest steps in any construction project. Starting early avoids unnecessary downtime.

Typical Ontario permits and documents include:

- Building permit application with engineer-stamped drawings.

- Site plan approval (for commercial or industrial builds).

- Grading or drainage permits for land alterations.

- Entrance permits for new driveways connecting to municipal roads.

Tower Steel Tip:

Tower Steel assists clients by preparing permit-ready drawings that meet Ontario Building Code and zoning standards – expediting municipal review.

Budget for Site Preparation

Even the best lot will need preparation before construction starts.

Costs vary widely depending on grading, excavation, and utility connections.

Common expenses:

- Clearing trees and vegetation.

- Excavation and backfilling.

- Gravel or crushed stone for base stabilization.

- Concrete forming for slab or frost wall foundations.

- Temporary site access or fencing.

Ontario example:

A logistics client near Kitchener budgeted $30,000 for site prep but saved 20% by choosing a naturally level parcel that required minimal grading.

Think About Future Expansion

If your business grows, you’ll want the flexibility to expand.

A smart site plan anticipates future needs without forcing a complete redesign later.

Tips for expansion-ready sites:

- Leave one or more building sides unobstructed.

- Ensure property boundaries allow for added square footage.

- Oversize utilities slightly for future load.

- Preserve access routes for future construction equipment.

Tower Steel Buildings designs modular systems that make expansion simple – often without new foundations or redesign fees.

Real Ontario Example – From Site Evaluation to Completion

A manufacturing client in Peterborough planned to build a 5,000 sq. ft. workshop on rural property.

After an initial consultation, Tower Steel conducted a site review that identified minor drainage issues and a need for frost-depth foundation design. Adjustments were made early, saving several weeks of rework later.

The project was completed on schedule, with an insulated, energy-efficient building that passed final inspection without issue.

This case shows how thorough site selection and early engineering coordination directly affect success.

Tower Steel Buildings: Supporting Smart Site Selection Across Ontario

Choosing the right site is one of the most important steps in any steel building project.

With years of experience across Ontario’s municipalities, soils, and climate zones, Tower Steel Buildings helps clients evaluate properties for practicality, compliance, and cost efficiency.

Our team supports you with:

- Zoning and setback verification.

- Soil testing coordination and foundation design.

- Drainage and grading consultation.

- Permit-ready drawings and site plans.

- Guidance for future expansion and access layout.

From Toronto to Thunder Bay, Tower Steel ensures your site is ready for safe, efficient construction – and your building performs as designed for decades to come.

Reviewed by the Tower Steel Buildings Engineering Team

This guide was reviewed by the Tower Steel Buildings Engineering Team, which oversees hundreds of Ontario projects annually. Their practical experience ensures every site evaluation recommendation is based on real construction results.

1. Do I need a soil test for my steel building site?

Yes. A geotechnical soil test identifies bearing capacity and frost depth, which determine your foundation type.

2. Can I build on uneven or sloped land?

Yes, but you’ll need proper grading and possibly retaining walls. Tower Steel engineers can adjust designs for these conditions.

3. How close can I build to a property line in Ontario?

Setbacks vary by municipality and zoning type. Always confirm with your local planning department before finalizing layout.

4. What is the best soil type for steel buildings?

Stable, well-drained soils such as gravel or sandy loam perform best. Heavy clay or fill soil may require reinforcement.

5. Does Tower Steel help with permits?

Yes. Tower Steel Buildings provides permit-ready, engineer-stamped drawings and guidance throughout the application process.