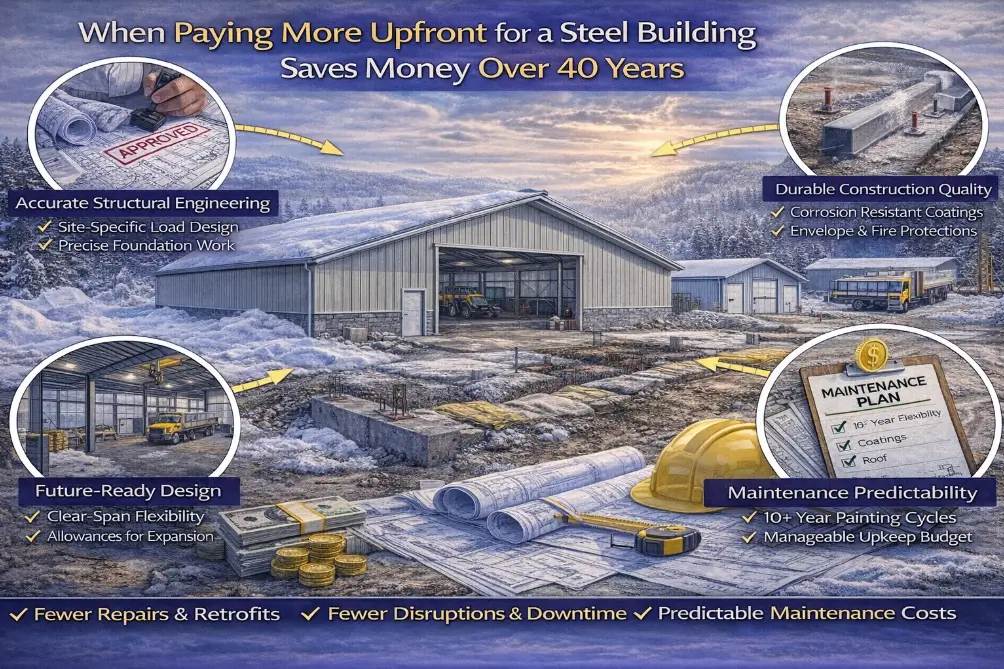

When buyers evaluate steel buildings, initial price often receives the most attention. That focus is understandable, but it is incomplete. For permanent steel buildings intended to operate for decades, long-term maintenance costs are one of the most significant drivers of total return on investment.

In Canada, where buildings face freeze-thaw cycles, snow loads, temperature swings, and inspection scrutiny, maintenance decisions made during design and fabrication directly affect operating costs, downtime, insurance acceptance, and asset value. Minimum durability and performance expectations are established through the National Building Code of Canada. A steel building with a lower upfront cost can easily become the more expensive option over its lifecycle if maintenance requirements are underestimated. This tradeoff is often misunderstood during pricing comparisons, as explained in why steel building quotes vary.

This article explains how long-term maintenance influences steel building ROI, what cost factors buyers often overlook, and how informed design choices reduce operating risk over time.

Who This Article Is For

This article is intended for owners planning permanent steel buildings where long-term operating cost, durability, and asset value matter. It may not apply to temporary storage structures or short-term enclosures where full lifecycle performance is not a priority.

Why Maintenance Costs Matter More Than Initial Price

A steel building is not a disposable product. It is infrastructure expected to perform reliably for 30 to 40 years or longer. Over that lifespan, maintenance costs often exceed the difference between competing upfront quotes.

Maintenance affects ROI in three critical ways:

- Direct expenses such as repairs, recoating, and component replacement

- Indirect costs such as downtime, access equipment, and labour disruption

- Risk exposure related to inspections, insurance, and resale value

A building that requires frequent intervention, even if structurally sound, consumes time and capital that erode long-term value.

Structural Steel Quality and Maintenance Exposure

Steel itself does not fail randomly. Long-term material performance is informed by research published by the National Research Council Canada. Maintenance requirements are strongly influenced by material selection, fabrication quality, and detailing accuracy. These decisions are established during steel building engineering approval, long before fabrication begins.

Coatings and Corrosion Protection

Coating systems play a major role in long-term performance. Protective coating requirements and performance benchmarks align with standards developed by CSA Group. Inadequate surface preparation or inappropriate coating selection increases the likelihood of corrosion, especially in humid or industrial environments.

Repainting or recoating structural steel is not a minor expense. It often requires:

- Access equipment or lifts

- Production shutdowns

- Surface preparation under controlled conditions

A more robust coating system at the fabrication stage typically reduces maintenance frequency and lowers total lifecycle cost. Lifecycle durability considerations are discussed further in over-engineering versus under-engineering steel buildings.

Fabrication Accuracy and Fit

Poor fabrication tolerances can introduce stress concentrations, water traps, or alignment issues that accelerate wear. Over time, these conditions increase the need for repairs and inspections.

Well-fabricated steel assemblies distribute loads evenly and minimize areas where moisture, debris, or chemicals accumulate.

Envelope Systems and Ongoing Maintenance

The building envelope is one of the most common sources of long-term maintenance cost. Many of these issues originate during steel building design and engineering, particularly around detailing and coordination.

Roof Systems

Roof design influences drainage, snow accumulation, and leak risk. Poor slope control, inadequate flashing, or improper fastener detailing can lead to recurring maintenance issues.

Roof repairs are disruptive and often expensive due to access requirements. Long-term ROI improves when roof systems are designed to shed water effectively and tolerate local climate conditions.

Wall Cladding and Penetrations

Wall systems must accommodate thermal movement, wind loads, and penetrations for services. Improper detailing around doors, louvers, and exhaust systems increases maintenance frequency.

Steel buildings designed with coordinated wall systems typically experience fewer envelope failures and lower repair costs.

Foundations and Slabs as Maintenance Drivers

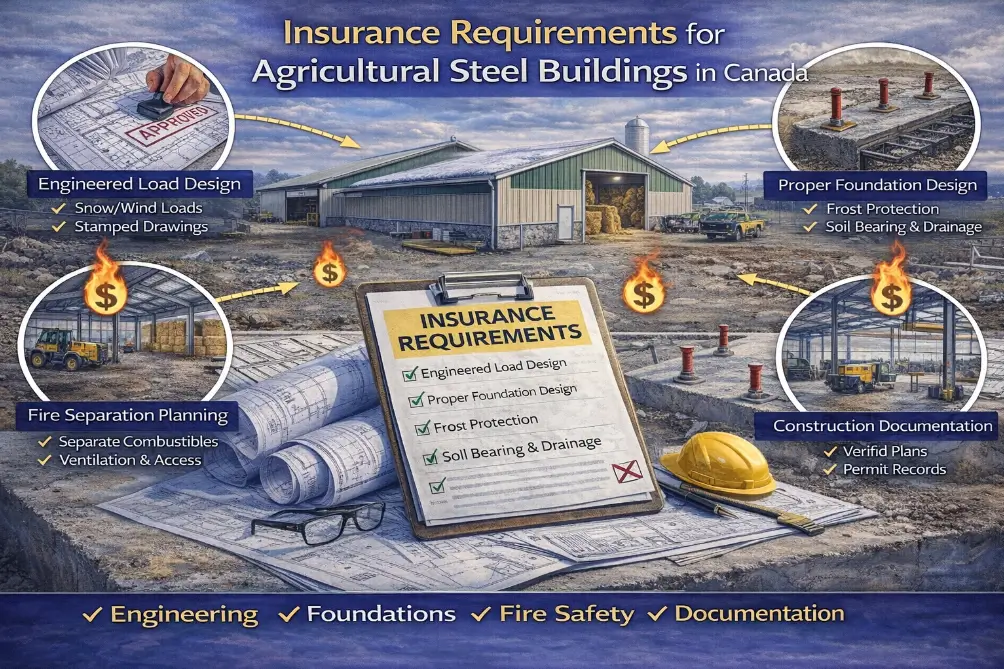

Foundation and slab performance have a direct impact on long-term maintenance, even though they are often considered separate from the steel structure. Long-term stability depends on proper steel building foundation design and soil coordination.

Settlement and Cracking

Uneven settlement can introduce misalignment, door operation issues, and structural stress. Correcting these problems after construction is costly and often disruptive.

Foundations designed with proper soil evaluation, frost protection, and load coordination reduce long-term corrective maintenance.

Drainage and Moisture Control

Poor site drainage increases moisture exposure at the foundation interface. These issues are commonly traced back to drainage and grading mistakes made during site preparation. Over time, this accelerates corrosion risk and slab deterioration.

Maintenance costs rise when drainage issues require retrofits or repeated surface repairs.

Mechanical Integration and Maintenance Access

Steel buildings often support mechanical systems such as ventilation, cranes, piping, and process equipment.

Load Coordination

When mechanical loads are not fully coordinated with structural design, retrofits become necessary. Reinforcing steel after installation is far more expensive than designing for known loads upfront.

Access for Maintenance

Maintenance access is a hidden cost driver. Access constraints often become visible during steel building erection planning rather than during design. Equipment that requires frequent servicing must be accessible without excessive lift rentals or production interruptions.

Steel buildings that incorporate maintenance access into their design reduce long-term operational disruption.

Inspection, Insurance, and Compliance Costs

Maintenance is not limited to physical repairs. It also includes compliance with inspection and insurance requirements.

Inspection Frequency

Buildings with recurring issues often attract closer inspection scrutiny. Structural condition and maintenance planning are reviewed by licensed engineers operating under national standards coordinated by Engineers Canada. Each inspection consumes time, administrative effort, and occasionally consultant fees.

Well-designed steel buildings with consistent performance tend to experience smoother inspection cycles.

Insurance Considerations

Insurers assess risk based on structural condition, maintenance history, and exposure. Buildings with lower maintenance demands often benefit from better coverage terms and fewer conditions.

Over time, insurance costs contribute significantly to total operating expense.

Maintenance, Downtime, and Operational Impact

Maintenance activities frequently require partial or full shutdowns of operations.

Downtime costs may include:

- Lost production

- Overtime labour to recover schedules

- Temporary relocation of equipment

Even small maintenance tasks can cascade into significant financial impact in manufacturing, logistics, or commercial environments.

Buildings designed to minimize maintenance intervention protect revenue continuity.

Lifecycle Cost Versus Initial Cost

ROI should be evaluated over the full service life of the building, not at contract signing.

A lower upfront cost may reflect:

- Reduced coating systems

- Simplified detailing

- Deferred engineering coordination

These savings often reappear later as maintenance expenses.

Conversely, slightly higher upfront investment in engineering, materials, and detailing often results in:

- Fewer repairs

- Longer service intervals

- Lower disruption to operations

Over decades, this difference becomes substantial.

Maintenance Performance and Asset Value

Steel buildings are often retained, expanded, or refinanced over time. Their long-term value depends on how well they continue to perform without excessive intervention.

Buildings with documented maintenance performance and predictable lifecycle costs consistently retain higher resale and refinancing value. This outcome is common in facilities built with long-term performance in mind, as seen in future-ready steel building design. Facilities that require frequent corrective work tend to lose appeal with buyers, lenders, and insurers, even when structurally sound.

Making Maintenance Part of the ROI Conversation

Buyers improve ROI outcomes when maintenance is discussed early, alongside design and pricing.

Key questions to consider include:

- What maintenance will be required in the first 10 years

- How often will coatings or envelope systems need attention

- Will access for maintenance disrupt operations

- How will inspection and insurance costs evolve

These questions shift decision-making from short-term cost to long-term value.

Conclusion

Long-term maintenance costs are one of the most influential factors in steel building ROI. They shape operating expense, risk exposure, and asset value long after construction is complete.

Steel buildings designed with durability, access, and climate realities in mind typically deliver stronger returns over their service life. Those built with minimal consideration for maintenance often cost more in the long run, regardless of their initial price.

In steel construction, the buildings that cost the least to maintain are almost always the buildings that deliver the highest return.

Reviewed by the Tower Steel Buildings Engineering Team

This article has been reviewed by the Tower Steel Buildings engineering team to ensure technical accuracy, practical relevance, and alignment with real-world steel building performance across Canadian climates.

Our review reflects decades of combined experience in steel building design, fabrication coordination, and long-term operational performance. The focus is on lifecycle behaviour, not theoretical assumptions, and on how maintenance decisions influence real ownership outcomes over time.

1. How long do steel buildings typically last in Canada?

Properly designed and maintained steel buildings commonly deliver 30 to 40 years of structural service life, with many performing well beyond that. Longevity depends on coating systems, foundation performance, environmental exposure, and adherence to planned maintenance rather than age alone.

2. Are steel buildings low maintenance compared to other construction types?

Steel buildings generally require less structural maintenance than wood or masonry systems. However, they are not maintenance-free. Roof systems, coatings, drainage, and envelope components still require periodic inspection and upkeep to protect long-term performance.

3. What maintenance items have the biggest impact on long-term costs?

The most influential maintenance factors are corrosion protection, roof integrity, foundation drainage, and envelope detailing around penetrations. Addressing these areas early and consistently reduces repair frequency and avoids larger corrective costs later.

4. Can poor maintenance affect insurance or financing?

Yes. Insurers and lenders often review maintenance history, inspection records, and observable condition when issuing or renewing coverage. Buildings with predictable maintenance performance and documented upkeep typically face fewer restrictions and lower risk assessments.

5. Does maintenance planning affect resale value?

It does. Buildings with consistent maintenance records, minimal corrective work, and predictable operating costs are easier to resell or refinance. Deferred maintenance or recurring issues often reduce buyer confidence and valuation.

6. Is higher upfront construction cost always better for ROI?

Not always, but strategic investment in durability, detailing, and access for maintenance often reduces long-term operating expense. ROI improves when design decisions lower future intervention rather than simply minimizing initial cost.