Steel buildings are often chosen for their predictability. Pre-engineered systems promise efficiency, durability, and cost control. Yet many Canadian buyers discover additional expenses only after a steel building contract has been signed.

These hidden costs in steel building projects are rarely the result of deception. In most cases, they come from assumptions made early, incomplete scope definitions, or responsibilities that were never clearly assigned. Understanding where these costs originate allows buyers to protect budgets, timelines, and long-term building performance.

This guide explains the most common hidden costs after signing a steel building contract, why they occur, and how informed buyers across Canada can avoid them.

Why Hidden Costs Appear in Steel Building Projects

A steel building contract typically prices a defined scope. That scope may include the steel structure itself, but steel buildings depend on foundations, site conditions, permits, erection, and coordination between multiple parties.

Hidden costs usually appear when one or more of the following occurs:

- Scope boundaries are misunderstood

- Site conditions differ from assumptions

- Code or permit requirements surface late

- Responsibilities between supplier, erector, and owner are unclear

A low initial contract value does not always reflect the total cost of completing a steel building project in Canada.

Foundation Design and Soil Conditions

Foundation-related costs are one of the most common sources of hidden expenses.

Many steel building contracts exclude foundation design and construction. While the steel manufacturer provides reaction loads, the foundation must be engineered separately based on site-specific soil conditions and frost depth.

Hidden costs arise when:

- Soil conditions require deeper or wider footings

- Frost depth requirements increase excavation and concrete volume

- Poor drainage demands engineered mitigation

- A geotechnical report is required after the contract is signed

Across Canada, soil conditions vary dramatically. Clay, silt, fill, and frost-susceptible soils can significantly alter foundation cost. When foundation assumptions made during quoting do not match site reality, budget overruns follow. Soil behaviour is one of the most common cost variables and is examined in detail in our guide on soil conditions that impact steel building foundations in Canada.

This is why foundation design is closely tied to overall steel building foundation design in Canada and should never be treated as an afterthought.

Permit and Code Compliance Gaps

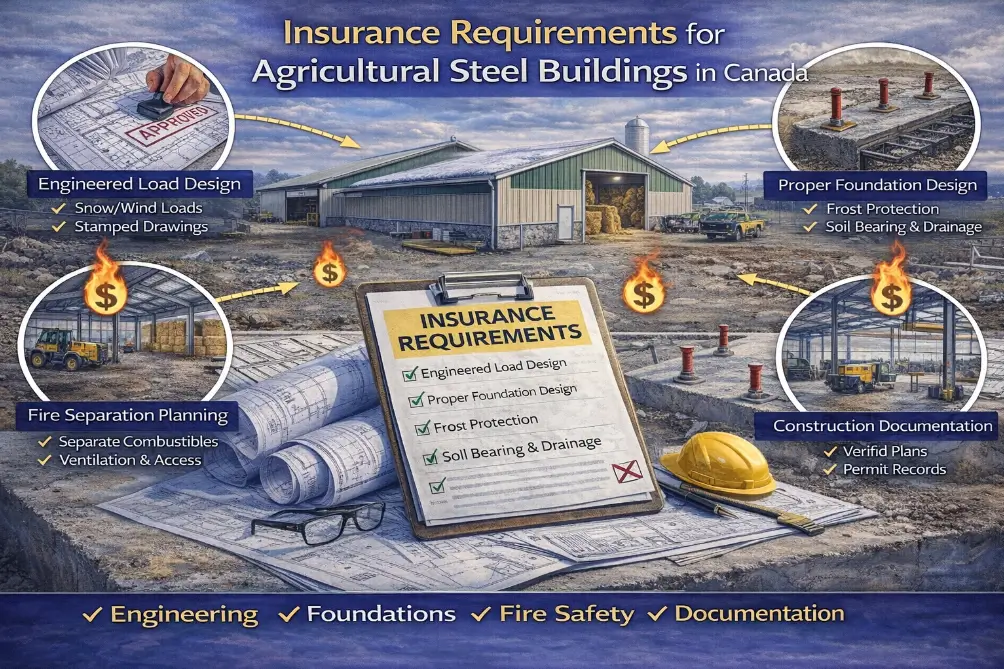

Another frequent source of hidden costs after signing a steel building contract involves permits and regulatory compliance.

Steel building pricing often assumes general code compliance, but enforcement and documentation requirements vary by municipality and province. These differences are often misunderstood, particularly when buyers do not fully understand how national and provincial building codes apply to steel structures.

Unexpected costs appear when:

- Local authorities require additional engineered drawings

- Zoning restrictions alter building height, placement, or use

- Snow, wind, or seismic loads exceed early assumptions

- Fire separation or occupancy classifications change

In some cases, buyers assume permit-ready drawings are included, only to learn later that additional stamped documents are required. Permit delays can also trigger indirect costs such as idle crews or extended equipment rentals.

Anchor Bolts and Erection Tolerances

Anchor bolt placement is one of the most underestimated risk areas in steel building projects.

Steel columns require precise anchor bolt alignment. If bolts are misplaced, correction costs can escalate quickly.

Hidden costs arise when:

- Anchor bolt templates are not used correctly

- Concrete is poured before final drawings are reviewed

- Epoxy anchoring or re-drilling becomes necessary

- Erection crews must stop work due to alignment issues

Many of these issues stem from gaps between design intent and field execution, which are explored further in our overview of steel building erection responsibilities in Canada.

These costs are rarely covered by the steel supply contract and typically fall directly on the owner.

Erection and Installation Assumptions

Many contracts price steel materials but exclude erection entirely. Even when erection is included, assumptions can lead to hidden expenses.

Common triggers include:

- Crane time exceeding allowances

- Restricted site access requiring specialized equipment

- Weather delays not factored into schedules

- Gaps between steel supplier scope and erector responsibilities

In remote regions or weather-sensitive areas of Canada, installation costs can fluctuate significantly if not planned in detail.

This is why steel building erection responsibilities should be clearly defined before a contract is signed.

Delivery, Freight, and Offloading Costs

Steel building delivery involves more than transporting materials from point A to point B.

Hidden delivery costs often include:

- Long-distance freight surcharges

- Fuel adjustments

- Permits for oversized loads

- Offloading equipment such as cranes or forklifts

Some contracts include delivery but exclude unloading. Others assume level access and clear staging areas. When those assumptions are incorrect, additional costs appear quickly.

Insulation and Condensation Control

Insulation is sometimes treated as an optional upgrade, but in Canadian climates it directly affects usability and durability.

Hidden costs appear when:

- Minimum insulation requirements are underestimated

- Vapor barrier systems are omitted

- Condensation control is addressed too late

- Heating system compatibility requires insulation changes

Retrofitting insulation after construction is far more expensive than addressing it during design.

Accessories and Functional Components

Secondary components are often overlooked during early pricing discussions.

Hidden costs commonly involve:

- Overhead and man doors

- Windows and daylighting systems

- Gutters, downspouts, and snow retention

- Ventilation and ridge vent systems

If these items are not clearly itemized in the contract, they may be added later at a premium.

Design Changes After Contract Signing

Design changes are one of the fastest ways for hidden costs to escalate.

Even minor changes such as door relocation, added openings, or roof slope adjustments can trigger:

- Engineering revisions

- Re-fabrication costs

- Schedule delays

- Permit resubmissions

Once fabrication begins, changes become significantly more expensive. Finalizing design details before signing a contract is one of the most effective cost-control measures available to buyers. The financial impact of late design revisions is examined in more detail in our analysis of how design changes impact steel building pricing.

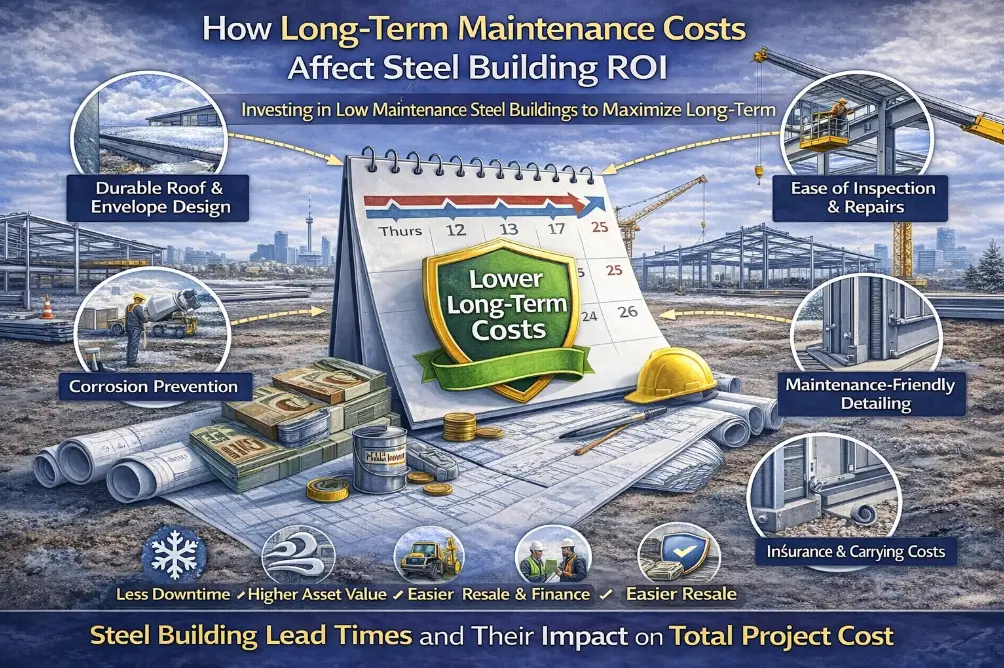

Warranty and Long-Term Performance Assumptions

Not all warranties cover the same risks.

Hidden costs emerge when buyers later discover that:

- Corrosion warranties depend on coatings and environment

- Paint systems must be upgraded for certain sites

- Foundation or erection issues void coverage

- Maintenance responsibilities were misunderstood

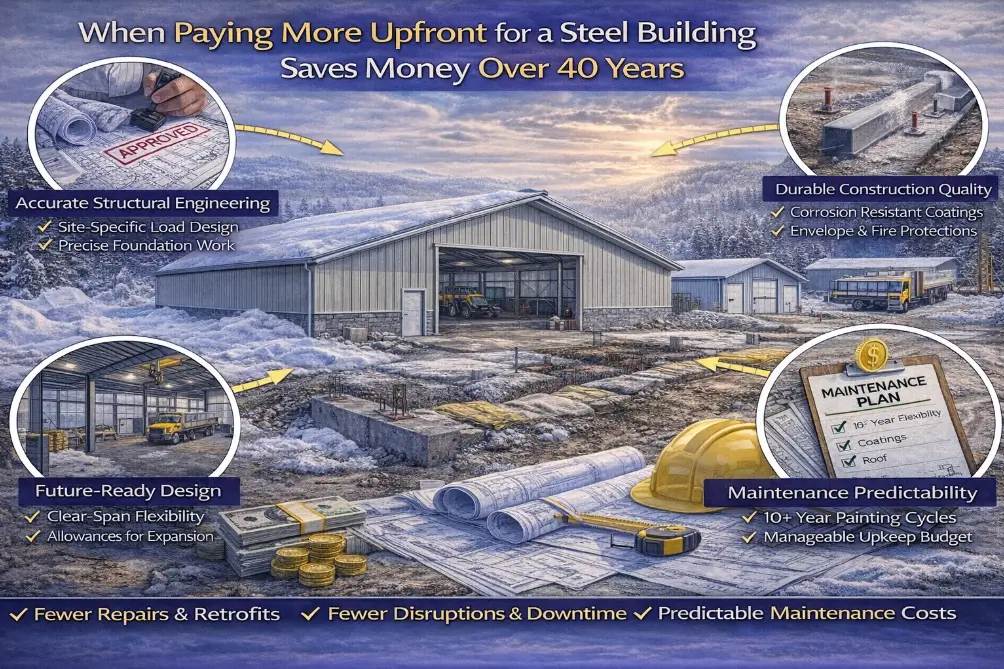

While many steel buildings are designed for 30 to 40 year structural performance, that longevity depends on coating selection, foundation quality, drainage, and ongoing maintenance.

Understanding how warranty terms connect to real-world conditions helps avoid long-term surprises.

Who Typically Pays for These Hidden Costs?

In most steel building projects, hidden costs are borne by the owner.

Unless a contract explicitly assigns responsibility elsewhere, expenses related to foundations, soil conditions, permit requirements, anchor bolt corrections, delivery logistics, and site coordination typically fall outside the steel supply scope.

This is why clarity at the contract stage is critical. Assumptions shift costs. Clear documentation assigns them.

Coordination Costs Between Trades

Steel building projects often involve independent contractors.

Hidden coordination costs arise when:

- Foundation and steel teams are not aligned early

- Erectors encounter missing or late information

- Utility connections are delayed

- Project management responsibilities default to the owner

Without a defined coordination strategy, small gaps can lead to costly delays.

How Informed Buyers Avoid Hidden Costs

Buyers who minimize hidden costs in steel building projects tend to follow similar practices:

- They demand itemized contracts

- They confirm inclusions and exclusions explicitly

- They involve foundation and permitting early

- They request site-specific engineering clarity

- They avoid decisions based solely on lowest price

Transparency before signing almost always costs less than corrections afterward.

This approach aligns closely with how experienced buyers review scope in steel building quote evaluations.

The Role of Experience in Cost Control

Hidden costs are rarely technical failures. They are planning failures.

Experienced teams understand where cost risks typically appear and address them early. This includes reviewing soil conditions, defining erection responsibilities, confirming code compliance, and coordinating trades before fabrication begins.

Experience reduces surprises because it anticipates them.

Final Thought for Canadian Steel Building Buyers

A steel building contract should never be treated as a fixed-price guarantee for the entire project. It is a starting point.

The cheapest steel building contract is rarely the lowest-cost project.

Buyers who understand where hidden costs after signing a steel building contract originate are better positioned to control budgets, protect timelines, and ensure long-term building performance.

Clarity is not an extra. It is the most valuable part of the contract.

Reviewed by the Tower Steel Buildings Engineering Team

This article has been reviewed by the Tower Steel Buildings Engineering Team to ensure technical accuracy, real-world relevance, and alignment with Canadian building practices. The insights shared reflect hands-on experience with steel building design, manufacturing coordination, foundation planning, and project execution across Canada.

1. What are the most common hidden costs in steel building projects?

The most common hidden costs in steel building projects include foundation design changes due to soil conditions, additional permit or code requirements (National Building Code of Canada), anchor bolt corrections, delivery and offloading expenses, and erection-related assumptions that were not clearly defined in the original contract.

2. Are hidden costs caused by steel building manufacturers?

In most cases, hidden costs are not caused by manufacturers but by gaps between what is included in the steel supply contract and what is required to complete the full project. These gaps often involve foundations, permits, site conditions, and coordination between multiple trades.

3. Who is usually responsible for paying hidden costs after signing a steel building contract?

Unless stated otherwise in the contract, hidden costs are typically the responsibility of the project owner. This includes expenses related to foundations, soil conditions, permitting requirements, site access, and erection coordination.

4. Can hidden costs be avoided in steel building projects?

Hidden costs can often be reduced or avoided by clearly defining scope before signing, confirming inclusions and exclusions in writing, addressing soil conditions early, and coordinating foundation, permitting, and erection requirements before fabrication begins.

5. Do hidden costs affect steel building warranties?

Yes. Certain hidden issues such as foundation deficiencies, improper anchor bolt installation, or drainage problems can affect warranty coverage if they fall outside the manufacturer’s responsibility. Understanding warranty conditions and installation requirements is essential for long-term protection.

6. Why is foundation planning critical to controlling steel building costs?

Foundation planning directly impacts excavation, concrete volume, frost protection, drainage, and anchor bolt placement. When foundation requirements are underestimated early, corrective work later can significantly increase total project cost.