Steel has become the preferred structural system for agricultural buildings across Canada because of its strength, fire resistance, and long service life. When properly engineered and constructed, steel farm buildings routinely perform for decades with predictable maintenance.

Yet many agricultural steel buildings show structural distress, moisture damage, corrosion, and performance issues far earlier than expected.

Early failure is rarely caused by steel itself.

It is almost always the result of design shortcuts, incomplete engineering, and site conditions that were never properly accounted for.

Understanding why farm steel buildings fail early helps owners avoid costly repairs, downtime, and premature replacement while ensuring long-term reliability.

Owners planning new agricultural facilities can request project guidance through our steel building quote and planning process.

Early Failure Is Usually Designed In, Not Caused by Use

Most failing agricultural steel buildings were never engineered for the realities they face.

This pattern is widely documented in cases involving under-engineered farm steel buildings in Canada, where simplified design assumptions lead directly to premature structural distress.

Common design assumptions that lead to early problems include:

- Generic snow load values instead of site-specific analysis

- Simplified framing layouts without proper load paths

- Foundations sized without soil conditions or frost movement considered

- Moisture control treated as optional rather than structural

- Agricultural use loads underestimated

These shortcuts may reduce initial price, but they shift cost and risk directly onto the owner over time.

Steel is highly efficient at transferring loads. That same efficiency means errors become visible sooner and compound faster than in loosely framed structures.

Underestimated Snow Loads Are a Primary Failure Driver

Roof failures and long-term structural deflection remain among the most common agricultural steel building issues in Canada.

This is usually caused by:

- Drift accumulation near ridges and adjacent structures

- Roof geometry concentrating snow loads

- Exposure conditions increasing localized loading

- Failure to account for regional extremes

Many farm buildings are designed using simplified snow assumptions rather than full engineering analysis.

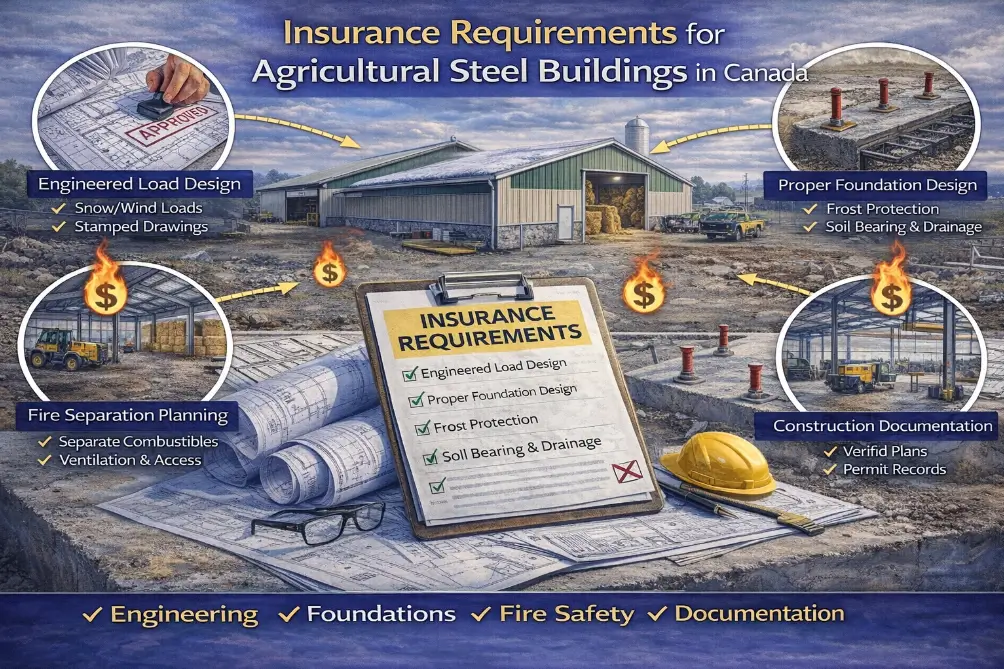

Canadian environmental loading requirements for structural design are defined by the National Building Code of Canada structural load requirements, which establish minimum snow load criteria based on geographic location and exposure.

Proper agricultural structural design must account for regional loading conditions identified in Canadian snow load mapping, which is explained in detail in our guide to steel building snow load zones in Canada.

For example, a farm equipment storage building designed with generic snow loads may appear fine for several seasons before drift accumulation permanently deforms roof frames, forcing costly reinforcement long before its expected lifespan.

Over time, repeated heavy snow seasons cause:

- Permanent frame deflection

- Connection fatigue

- Roof panel distortion

- Progressive structural weakening

The building may not collapse, but its service life is significantly shortened.

Foundations That Do Not Match Steel Structural Behavior

Steel buildings rely on precise load transfer. Even small foundation movement can create serious performance issues.

Common agricultural foundation problems include:

Many of these issues originate from inadequate frost protection and soil response to seasonal freezing, which is why understanding frost depth in steel building foundations is essential in Canadian agricultural construction.

- Frost heave lifting isolated footings

- Differential settlement across long building lengths

- Slab movement affecting frame alignment

- Poor drainage saturating bearing soils

When foundations are not engineered alongside steel reactions, the structure experiences:

- Frame twist

- Roof leakage

- Connection stress

- Accelerated corrosion

Many early failures originate below grade long before they appear in the steel frame. Subsurface performance is strongly influenced by soil composition, drainage behaviour, and bearing capacity, all of which are examined in our technical guide to soil conditions for steel building foundations in Canada.

Moisture and Condensation Destroy Buildings from the Inside Out

Agricultural environments generate high humidity through:

- Livestock respiration

- Washdown operations

- Stored crops

- Seasonal temperature swings

Without proper moisture control design, condensation forms on:

- Roof panels

- Purlins

- Columns

- Fasteners

This leads to:

- Corrosion

- Mold

- Insulation degradation

- Reduced structural life

Buildings that appear structurally sound often fail internally due to moisture-driven deterioration.

Agricultural Loads Are Frequently Underestimated

Load assumptions must align with regulatory requirements and operational realities defined in agricultural steel building code requirements in Ontario, which establish minimum structural and usage standards.

Farm buildings experience loads that standard storage buildings do not:

- Equipment impact and vibration

- Hay storage weight

- Grain bin interactions

- Livestock movement loads

- Suspended systems

When these loads are not explicitly engineered, frames slowly accumulate stress beyond design assumptions.

This results in:

- Connection loosening

- Member fatigue

- Permanent deformation

- Reduced safety margins

What seems minor operationally becomes significant structurally over years of use.

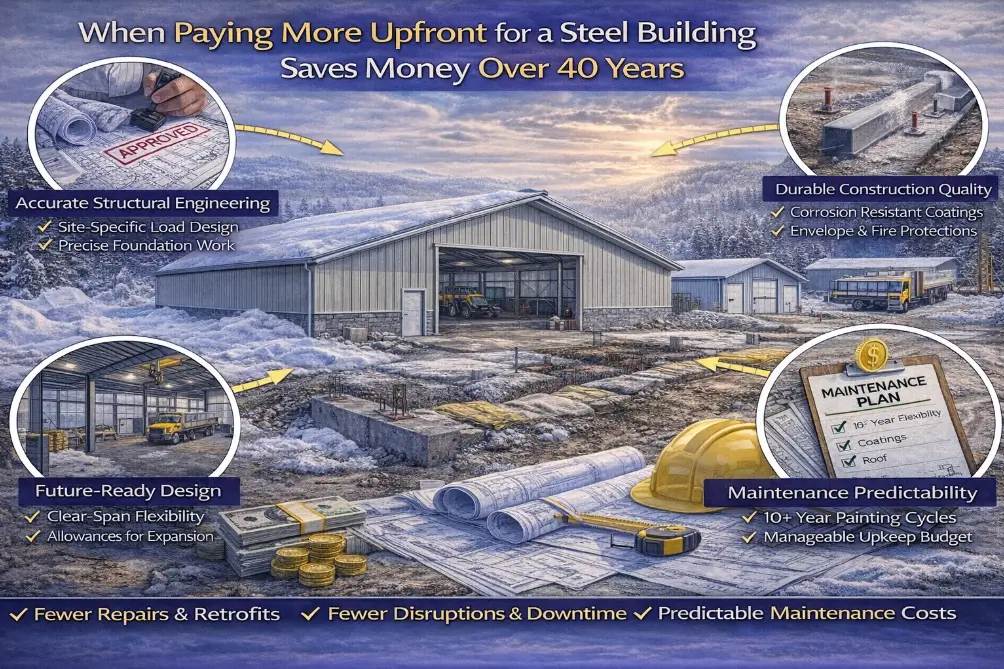

Design Conservatism Is Often Mistaken for Over-Engineering

Some owners avoid full engineering to reduce cost, believing conservative design inflates price.

In reality:

Conservative engineering means accurately accounting for real site conditions and operational loads. This reflects the critical distinction explained in our technical analysis of over-engineering vs under-engineering in steel buildings, where accuracy is often mistaken for excess.

It does not mean unnecessary steel.

Proper engineering eliminates:

- Repair cycles

- Reinforcement retrofits

- Operational disruptions

- Insurance complications

Buildings designed properly cost less over their full life than buildings corrected later.

Lifecycle performance differences are explored further in our analysis of long-term cost savings in steel building ownership.

Early Failures Often Follow the Same Pattern

Across agricultural steel building projects in Canada, early distress typically follows this sequence:

- Simplified design assumptions

- Inadequate foundation coordination

- Moisture issues begin

- Frame movement becomes visible

- Repairs and reinforcements follow

- Building value declines

Each stage compounds the next.

Climate Magnifies Small Errors Over Time

Canada’s climate accelerates structural problems through:

- Freeze-thaw cycling

- Snow load accumulation

- Seasonal moisture swings

- Ground movement

Minor design shortcuts become major failures under repeated exposure.

Buildings that might survive in mild climates often struggle in agricultural Canadian environments.

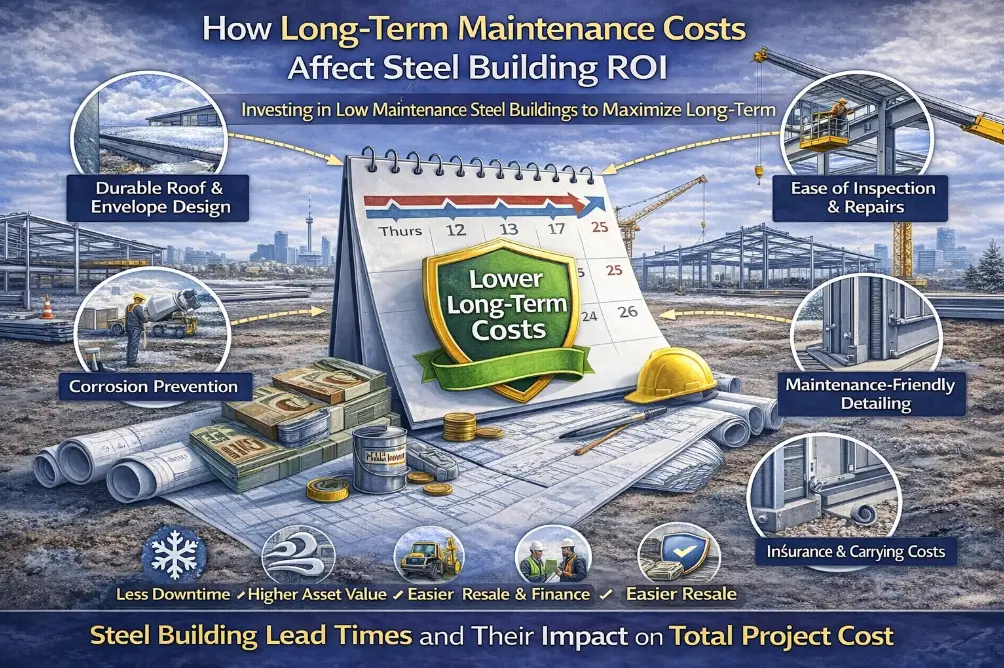

Proper Engineering Extends Service Life Dramatically

When farm steel buildings are properly engineered, they typically demonstrate:

- Stable foundations

- Controlled moisture environments

- Predictable structural behavior

- Minimal long-term maintenance

- Strong resale value

The difference is not material quality alone.

It is engineering discipline.

Why Early Failure Is Largely Preventable

Nearly all common farm steel building failures can be avoided through:

- Site-specific load analysis

- Coordinated foundation design

- Moisture control planning

- Proper agricultural load assumptions

- Engineered connections and framing

These steps are not luxury upgrades.

They are the baseline of long-term performance.

The Real Cost of Early Failure

Early failure rarely means collapse.

It means ongoing cost.

Owners face:

- Structural reinforcement expenses

- Roof replacement

- Moisture remediation

- Downtime and lost productivity

- Reduced asset value

Over a building’s lifespan, these costs frequently exceed the original construction price difference between engineered and shortcut designs.

Long-Term Thinking Protects Agricultural Investment

Farm steel buildings are infrastructure, not temporary shelters.

Owners planning permanent agricultural facilities often evaluate purpose-built farm steel buildings engineered for Canadian conditions to ensure long-term operational reliability.

They support:

- Livestock welfare

- Crop protection

- Equipment investment

- Operational efficiency

Designing for decades rather than seasons protects both finances and operations.

Final Perspective

Farm steel buildings do not fail early because steel is inadequate.

In Canada, many engineered steel building systems are designed in accordance with CSA A660 steel building certification standards, which establish performance and quality requirements for structural steel building systems.

They fail early because:

- Loads are underestimated

- Foundations are simplified

- Moisture is ignored

- Engineering is deferred

In agricultural construction, performance is designed in from the beginning.

Buildings that receive proper engineering attention almost always outperform those built on shortcuts.

Early failure is not bad luck.

It is usually the predictable outcome of early assumptions.

Reviewed by the Tower Steel Buildings Engineering Team

This article has been reviewed by the Tower Steel Buildings Engineering Team to ensure accuracy in structural design principles, agricultural load considerations, Canadian climate impacts, and long-term steel building performance.

1. Why do many farm steel buildings fail sooner than expected?

Most early failures are caused by incomplete engineering, underestimated snow and operational loads, foundation movement, and poor moisture control. The steel itself rarely fails. Design shortcuts that ignore site conditions and agricultural use are usually responsible.

2. How long should a properly engineered farm steel building last in Canada?

When engineered correctly and maintained reasonably, agricultural steel buildings in Canada commonly perform for 30 to 50 years or longer. Service life depends on structural design, foundation stability, corrosion protection, and moisture management.

3. Are snow loads really that critical for farm buildings?

Yes. Snow loads are one of the leading causes of roof deflection and long-term structural stress in agricultural steel buildings. Drift accumulation, roof geometry, and regional climate variations often govern design more than average snowfall levels.

4. Can foundation problems cause steel buildings to fail?

Absolutely. Steel structures transfer loads very efficiently, which makes them sensitive to foundation movement. Frost heave, settlement, and poor drainage can twist frames, loosen connections, and create long-term structural issues even when the steel itself is strong.

5. Why is moisture such a big issue in agricultural steel buildings?

Farm environments generate high humidity from livestock, washdowns, and stored crops. Without proper vapor control and ventilation, condensation forms on steel components, leading to corrosion, insulation breakdown, and reduced structural lifespan.

6. Are lower-priced farm steel buildings more likely to fail early?

Often yes. Lower initial prices frequently result from simplified engineering, generic load assumptions, and minimal foundation coordination. These shortcuts reduce upfront cost but increase long-term repair, maintenance, and failure risk.

7. What engineering steps prevent early steel building failure on farms?

Key protections include site-specific snow and wind load analysis, coordinated foundation design, moisture control planning, proper agricultural load assumptions, and fully engineered framing and connections.

8. Can early steel building problems be repaired?

Many issues can be corrected through reinforcement, drainage upgrades, corrosion treatment, or foundation stabilization. However, repairs are usually expensive and disruptive compared to building correctly from the beginning.

9. Do agricultural steel buildings need different engineering than warehouses or storage buildings?

Yes. Farm buildings experience unique loads from equipment, livestock, moisture exposure, and operational demands. Designs suitable for dry storage often perform poorly in agricultural environments if these factors are not addressed.

10. How can owners ensure their farm steel building is engineered properly?

Owners should confirm that full structural engineering is provided, including site-specific load calculations, foundation reactions, moisture management considerations, and connection design. Avoid relying on generic plans or preliminary designs.