Agricultural steel buildings are often viewed as simpler structures compared to commercial or industrial facilities. Because of this perception, many farm buildings across Canada are designed with reduced engineering oversight, minimal load analysis, or assumptions that would never be accepted in other construction sectors.

While some agricultural structures qualify for relaxed regulatory requirements, under-engineering is not the same as appropriate design. Over time, insufficient engineering frequently leads to structural movement, roof distress, condensation issues, foundation cracking, insurance complications, and costly retrofits.

Understanding why agricultural steel buildings are commonly under-engineered helps owners make better decisions before problems become permanent.

The Misconception That Farm Buildings Are “Low Risk”

A major driver of under-engineering is the belief that agricultural buildings carry less structural risk.

In reality, many farm buildings:

- Span large open areas with heavy snow accumulation

- Store high-value equipment, grain, or livestock

- Operate year-round under extreme Canadian weather

- Experience moisture, condensation, and corrosion exposure

From a structural perspective, these demands are often greater than those in many commercial facilities.

Yet agricultural buildings are frequently treated as temporary or lightly loaded structures during design.

Regulatory Exemptions Are Often Misunderstood

Across Canada, certain agricultural buildings qualify for modified permitting or building code treatment. These exemptions were created to reduce administrative burden for farmers, not to encourage minimal structural performance.

Problems arise when exemptions are interpreted as permission to reduce engineering entirely. This misunderstanding is common in farm construction and is explored further in agricultural steel building code differences in Ontario.

Common shortcuts include:

- Using generic building templates without site-specific loads

- Skipping professional foundation design

- Assuming southern snow loads apply in northern regions

- Eliminating deflection and drift analysis

- Simplifying bracing systems

While these approaches may pass minimal permitting requirements, they rarely represent optimal long-term performance.

Snow Load Is Frequently Underestimated

Snow load is the single largest structural demand on most agricultural steel buildings.

Under-engineering often occurs when:

- Regional snow variations are ignored

- Drift accumulation near roof steps is overlooked

- Roof slope effects are simplified

- Ice buildup is not considered

- Climate change intensity trends are ignored

Many roof failures on farm buildings are not due to material quality but to underestimated snow loading during design. This is why understanding steel building snow load zones in Canada is critical when engineering agricultural structures for regional climate conditions.

Once a roof experiences excessive deflection or connection distress, structural lifespan is permanently reduced.

Foundations Are Commonly Treated as Secondary Components

Another major cause of under-engineering is inadequate foundation design. Professional steel building foundation design ensures frost protection, load coordination, and long-term structural stability in agricultural projects.

In agricultural projects, foundations are often:

- Designed without geotechnical input

- Sized using generic slab thickness rules

- Installed without frost protection optimization

- Built without coordination with steel reactions

- Sloped improperly for drainage

Steel buildings transfer loads very precisely. Even small foundation movement can lead to:

- Frame misalignment

- door binding

- cladding cracking

- roof leaks

- connection fatigue

Foundation issues rarely appear immediately, but they compound over years. Long-term structural movement is strongly influenced by site conditions, making soil conditions and steel building foundations in Canada a key factor in agricultural building durability.

Ventilation and Condensation Are Rarely Engineered

Agricultural buildings experience high moisture loads from:

- livestock respiration

- manure handling

- grain drying

- temperature swings

- winter freeze cycles

When condensation control is not engineered, moisture accumulates inside wall cavities and roof systems.

This leads to:

- corrosion of steel members

- insulation breakdown

- mold growth

- fastener deterioration

Under-engineering ventilation is one of the fastest ways to shorten building life.

Structural Connections Are Often Simplified

In properly engineered steel buildings, connections are among the most carefully analyzed elements.

In under-engineered farm buildings, connection design is frequently:

- standardized rather than calculated

- reduced for material savings

- not reviewed for fatigue cycles

- not optimized for erection loads

Most structural failures begin at connections, not primary frames.

Once a connection yields or loosens, load redistribution increases stress throughout the structure.

Cost Pressure Encourages Engineering Reduction

Agricultural construction budgets are often tight. As a result, engineering is sometimes viewed as an area to reduce cost rather than as a risk management tool.

Common cost-cutting moves include:

- removing professional foundation design

- limiting structural calculations

- eliminating site-specific analysis

- using lighter framing than recommended

While these reductions may save money initially, they frequently result in higher maintenance, repairs, insurance issues, and shortened building lifespan.

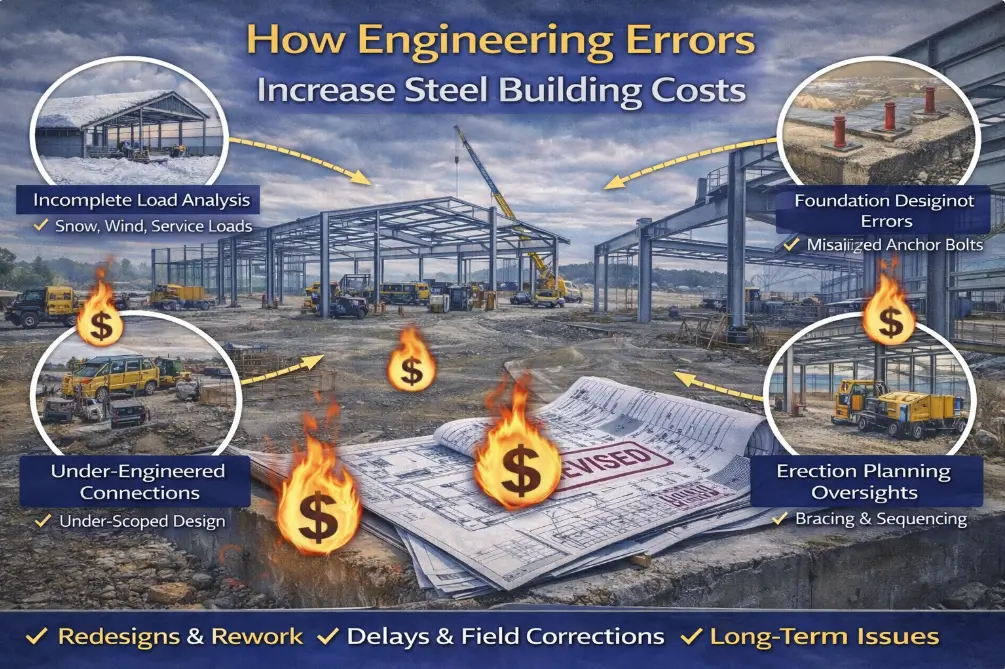

Many of these long-term costs stem from early design shortcuts, as explained in how engineering errors increase steel building costs.

Under-Engineering Often Goes Undetected for Years

One reason under-engineering persists is that problems develop slowly.

Early signs may include:

- minor roof sagging

- small foundation cracks

- condensation drip lines

- misaligned doors

- increasing corrosion

Owners often assume these are normal aging effects.

In reality, they are early indicators of structural stress.

By the time visible damage appears, corrective costs are far higher than proper engineering would have been initially.

Insurance and Financing Are Increasingly Affected

Modern insurers and lenders are paying closer attention to structural documentation.

Under-engineered buildings may experience:

- higher premiums

- limited coverage

- claim exclusions

- financing complications

- resale valuation issues

Many insurance companies now expect engineering even for agricultural structures that qualify for code exemptions. This shift reflects broader construction risk research published by the Insurance Bureau of Canada, which tracks climate exposure and structural loss trends nationwide.

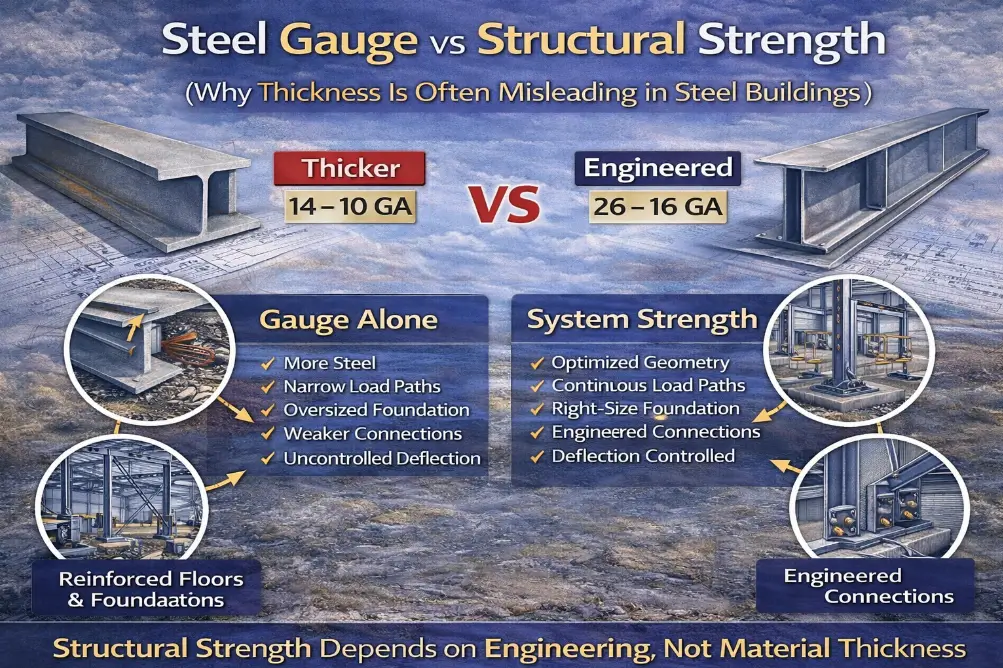

Conservative Design Does Not Mean Over-Engineering

There is a critical distinction between conservative design and over-engineering.

Conservative design means:

- accurately applying site-specific loads

- accounting for climate exposure

- designing for long-term performance

- coordinating foundations properly

Over-engineering means adding unnecessary material without structural need.

Proper engineering seeks efficiency and durability, not excessive steel.

Why Integrated Engineering Improves Agricultural Buildings

Agricultural steel buildings perform best when:

- structural design

- foundation engineering

- moisture control

- erection sequencing

- site conditions

are coordinated as a system.

Organizations such as Tower Steel Buildings apply this integrated approach by aligning engineering, fabrication, and site coordination early, helping agricultural buildings perform reliably under real Canadian conditions.

Long-Term Performance Is the True Cost Metric

The real cost of a steel farm building is not the purchase price.

It is measured by:

- maintenance frequency

- structural repairs

- insurance stability

- operational downtime

- resale value

- service life

Buildings designed properly often outperform lightly engineered structures by decades. This performance difference is reflected in ownership economics such as long-term maintenance costs and steel building ROI.

Key Takeaway

Many agricultural steel buildings are under-engineered not because steel is weak, but because assumptions replace analysis.

Snow loads, foundations, moisture, and connections demand the same professional attention in farm buildings as in commercial structures.

These structural requirements are governed nationally under the National Building Code of Canada, which establishes load design and safety standards across all provinces.

In Canadian climates, proper engineering is not an upgrade. It is the foundation of durability, safety, and long-term value.

Reviewed by the Tower Steel Buildings Engineering Team

This article has been reviewed by the Tower Steel Buildings Engineering Team to ensure technical accuracy, alignment with Canadian building practices, and real-world agricultural construction conditions across Canada.

1. Are agricultural steel buildings required to be fully engineered in Canada?

Requirements vary by province and municipality. Some agricultural buildings qualify for modified permitting processes, but structural engineering is still strongly recommended to ensure proper snow load capacity, foundation performance, and long-term safety. Many insurers and lenders now expect engineered documentation regardless of exemptions.

2. Why do many farm steel buildings experience roof sag or structural movement?

These issues are commonly caused by underestimated snow loads, simplified framing design, and insufficient foundation coordination. When structural reactions and climate conditions are not properly analyzed, stress accumulates over time, leading to visible movement or distress.

3. Does under-engineering reduce the upfront cost of a steel building?

It may reduce initial pricing, but it almost always increases total ownership cost. Repairs, reinforcement, moisture damage, insurance complications, and shortened building lifespan typically exceed the cost of proper engineering within the first several years of operation.

4. How important is foundation design for agricultural steel buildings?

Foundations are critical. Steel structures transfer loads precisely, and even small settlement or frost movement can cause frame misalignment, roof leaks, and connection fatigue. Proper geotechnical review and engineered foundation coordination are essential for long-term performance.

5. Can condensation and moisture damage be prevented in farm steel buildings?

Yes, when ventilation, insulation systems, and vapour control are engineered correctly. Many agricultural buildings suffer corrosion and structural deterioration because moisture management was not designed as part of the building system.

6. Do snow load requirements differ significantly across Canada?

Yes. Snow load values vary widely by region and are affected by roof geometry, drifting, exposure, and climate conditions. Designs based on generic assumptions often fail to account for local extremes, which is a major cause of agricultural building distress.

7. Are under-engineered buildings harder to insure?

Increasingly, yes. Many insurance providers now request structural drawings, load calculations, and professional engineering stamps. Buildings lacking documentation may face higher premiums, limited coverage, or claim restrictions.

8. How long should a properly engineered agricultural steel building last?

When engineered correctly and maintained properly, steel farm buildings often achieve service lives of 40 years or more, with predictable maintenance costs and structural stability.

9. Is conservative engineering the same as over-engineering?

No. Conservative engineering means accurately accounting for climate loads, site conditions, and long-term performance. Over-engineering involves unnecessary material use. Proper engineering seeks efficiency, safety, and durability, not excess steel.