Drainage and grading issues are one of the most common reasons steel building projects stall after permits are issued. They are also among the most misunderstood. Many owners assume that once a site looks flat and dry, it is ready for foundations and steel delivery. In reality, poor drainage and improper grading can halt a project before the first column is set.

Steel buildings are precise structural systems. They depend on accurate load transfer, stable foundations, and predictable soil behaviour. When water management is overlooked, even well engineered steel buildings face delays, failed inspections, and costly rework.

This guide explains the most common drainage and grading mistakes that delay steel building projects across Canada, why steel buildings are particularly sensitive to these issues, and how early planning can prevent weeks or months of lost time.

Why Drainage and Grading Are Critical for Steel Buildings

Steel buildings differ from many other construction systems in how they interact with foundations and site conditions. Steel frames transfer loads directly and efficiently through columns and base plates into the foundation. This efficiency means steel buildings do not tolerate uneven settlement, water softening, or frost movement well.

Poor drainage does not simply create muddy working conditions. It changes soil bearing capacity, accelerates frost heave, and introduces long term settlement risk. These issues become visible quickly in steel structures because the frame alignment, bolt tolerances, and column plumbness are precise.

When drainage or grading problems appear, inspectors respond accordingly.

Municipal inspectors will not approve foundations where drainage paths are unclear or water accumulation is visible, regardless of how well the steel building is engineered.

This is why drainage and grading are not cosmetic site concerns. They are stop-work issues.

The Most Common Drainage and Grading Mistakes

Mistake 1: Assuming Flat Means Properly Graded

A level site is not the same as a properly graded site. Grading must direct surface water away from foundations, not simply create a smooth surface for construction.

Common errors include:

- Flat pads with no positive slope away from the building

- Slopes that direct water toward column lines

- Inconsistent grading that traps water along foundation edges

Steel foundations require controlled water movement. Standing water around footings or slabs is a red flag for inspectors and engineers alike.

Mistake 2: Ignoring Seasonal Water Conditions

Many sites appear dry during summer site visits but experience significant water accumulation during spring melt or fall rains. Canadian climate conditions demand seasonal awareness.

Typical oversights include:

- No allowance for snowmelt runoff

- Failure to account for high water tables during spring

- Overlooking clay soils that retain moisture

Seasonal moisture problems are especially common in sites with challenging soil conditions, which directly affect drainage performance.

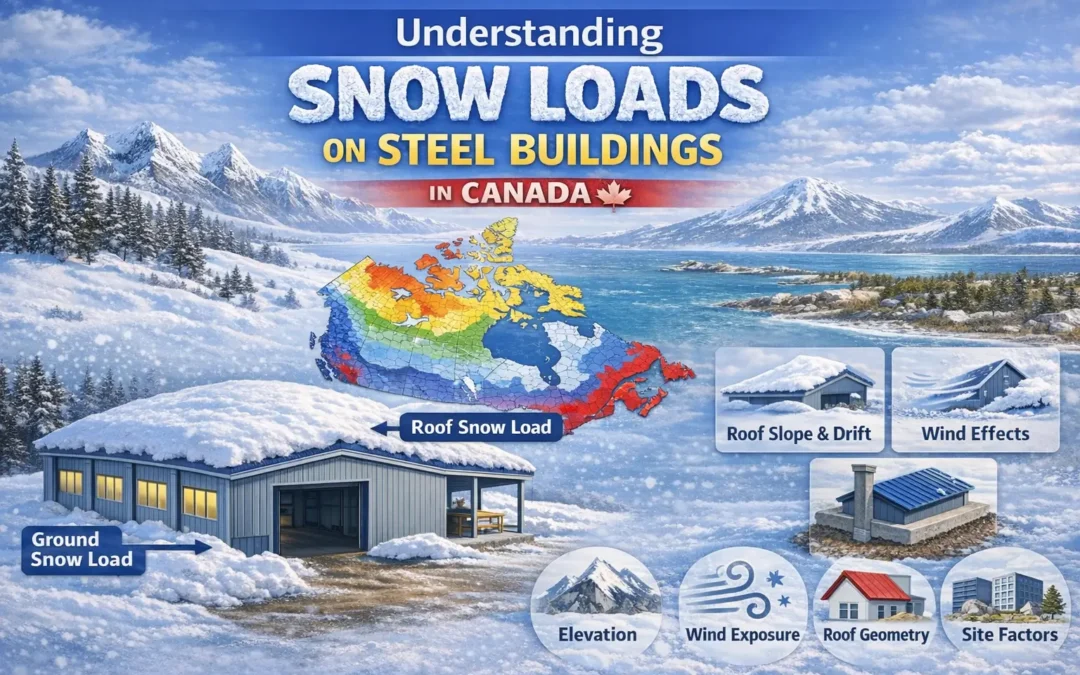

Seasonal moisture, frost depth, and climatic exposure are addressed in the National Building Code of Canada, which informs foundation design assumptions.

Foundations poured during dry conditions may show weather exposure, settlement, or cracking once seasonal moisture returns. These issues are difficult and expensive to correct after steel erection begins.

Mistake 3: Inadequate Perimeter Drainage

Perimeter drainage is often simplified or omitted entirely to reduce upfront costs. This is a short-sighted decision.

Common perimeter drainage failures include:

- No granular drainage layer around foundations

- Missing or improperly sloped drain tile

- Drain outlets that discharge toward the building pad

Long-term settlement and frost movement related to poor drainage are documented through research by the National Research Council of Canada.

Water that cannot escape will find the path of least resistance, often beneath footings or slabs. Over time, this leads to soil movement and uneven bearing conditions.

Mistake 4: Relying on “Water Will Find Its Way Out”

This assumption is one of the most damaging misconceptions in site preparation. Water does not magically resolve drainage problems. It accumulates where resistance is lowest.

Steel buildings amplify this issue because:

- Column base plates transfer concentrated loads

- Small areas of softened soil can affect structural alignment

- Foundation tolerances are tighter than wood construction

What appears to be a minor puddle can quickly become an inspection failure.

Mistake 5: Minor Grade Changes After Engineering Approval

Even small grading changes after foundation drawings are approved can cause major problems. Adjusting elevations without engineering review may alter load paths or drainage assumptions.

Examples include:

- Raising surrounding grade levels

- Adding fill against foundation walls

- Redirecting runoff from adjacent properties

Even minor grade changes can conflict with approved steel foundation drawings, triggering re-inspection and revised engineering.

These changes often trigger re-inspection requirements and, in some cases, revised engineering.

Mistake 6: Pouring Foundations Before Site Conditions Are Resolved

Project pressure sometimes leads to foundations being poured before drainage issues are fully addressed. This almost always backfires.

Foundations poured too early may show weather exposure, water infiltration, or bearing issues before steel arrives. At that point, corrective work is disruptive and costly.

Each failed inspection adds rebooking costs, schedule disruption, and administrative delay that compounds quickly across the project timeline.

Why Steel Buildings Are Less Forgiving Than Other Structures

Steel buildings rely on predictable foundation behaviour. Unlike wood framing, steel does not flex or absorb uneven movement gracefully. Small site errors become visible quickly.

Steel structures:

- Reveal settlement through column misalignment

- Expose drainage failures through slab cracking

- Transfer load changes directly to connections

This sensitivity is not a weakness. It is a reflection of precision engineering. But it does require site preparation to meet the same standard.

How Drainage and Grading Delays Affect the Entire Project

Drainage issues rarely exist in isolation. They trigger a chain reaction that affects multiple stages of the project.

Common consequences include:

- Failed foundation inspections

- Delayed steel delivery schedules

- Idle erection crews

- Extended equipment rentals

- Financing and insurance complications

Poor site conditions are a common reason steel building erection is delayed after foundations are completed.

Once steel delivery is delayed, coordination across trades becomes increasingly difficult. What began as a grading oversight can delay occupancy by weeks or months.

The Role of Engineering and Site Coordination

Drainage and grading should be addressed during early project planning, not after permits are issued. This requires coordination between:

- Site contractors

- Geotechnical consultants

- Structural engineers

- Municipal inspectors

Engineering drawings assume certain site conditions. When those assumptions are not met, revisions become unavoidable. These assumptions are defined during steel building foundation design, where drainage, soil behaviour, and frost depth are established.

For steel building foundation design in Canada, drainage planning must align with soil conditions, frost depth, and regional climate patterns. This is not a one-size-fits-all exercise.

Preventing Drainage and Grading Delays

Successful steel building projects share common site preparation practices.

Best practices include:

- Conducting soil testing before finalizing foundation design

- Establishing positive drainage away from all foundation edges

- Accounting for seasonal water conditions

- Completing grading and drainage before scheduling foundation pours

- Confirming site readiness prior to steel delivery

These steps are part of proper steel building site preparation and must be completed before foundations and steel delivery are scheduled.

These steps cost far less than correcting problems after construction begins.

Why Early Planning Saves More Than Time

Drainage and grading errors do not just delay schedules. They increase project risk. Failed inspections raise scrutiny. Revisions increase costs. Confidence erodes between project stakeholders.

Steel buildings reward preparation. When the site is ready, construction proceeds efficiently and predictably. When it is not, delays are unavoidable.

Most steel building delays blamed on manufacturing or delivery actually originate at the site level.

How This Fits Into the Bigger Picture

Drainage and grading directly influence:

- Steel building foundation design in Canada

- Long term structural performance

- Inspection outcomes

- Insurance and warranty confidence

They also connect closely with topics such as CSA A660 certification, soil conditions, and foundation engineering. These elements work together. Ignoring one weakens the entire system.

Final Thoughts

Drainage and grading mistakes are among the most preventable causes of steel building delays. They are also among the most costly when ignored.

A site that looks ready is not always ready. Steel buildings demand precision from the ground up. When drainage paths are clear, grades are correct, and seasonal conditions are understood, steel projects move forward smoothly.

Address drainage early, verify grading carefully, and treat site preparation with the same seriousness as structural design. Doing so protects schedules, budgets, and long term performance.

Reviewed by the Tower Steel Buildings Engineering Team

This article has been reviewed by the Tower Steel Buildings Engineering Team to ensure technical accuracy, alignment with Canadian site preparation standards, and consistency with real-world steel building foundation and erection practices.

The review reflects decades of combined experience working with municipal inspectors, geotechnical consultants, site contractors, and steel erectors across commercial, agricultural, and industrial projects throughout Canada.

1. Who is responsible for drainage and grading on a steel building project?

Drainage and grading are typically the responsibility of the property owner or site contractor, not the steel building manufacturer. However, foundation design assumes specific site conditions, so poor grading can invalidate those assumptions and delay approval.

2. Can drainage issues delay steel building erection even after foundations are poured?

Yes. Standing water, saturated soils, or unclear drainage paths can prevent steel erection from proceeding. Inspectors may halt work until site conditions meet approved drawings and safety requirements.

3. Do drainage problems affect foundation inspections?

Absolutely. Municipal inspectors will not approve foundations where water accumulation is visible or drainage paths are unclear, even if the structural design itself is sound.

4. Can poor drainage void steel building warranties?

While steel warranties typically cover manufactured components, foundation and site-related issues can affect long-term performance. Persistent water exposure can contribute to settlement, corrosion risk at base plates, and structural misalignment.

5. Should drainage be addressed before or after steel building engineering is completed?

Drainage and grading should be evaluated before final foundation and steel engineering is completed. Site conditions directly influence footing design, slab elevation, and long-term stability.

6. How early should grading be completed before steel delivery?

Grading and drainage should be fully completed and inspected before foundations are poured and well before steel delivery is scheduled. This reduces reinspection risk, protects schedules, and avoids costly delays.